Water-adhesive composite waterproof pulp and preparation method thereof

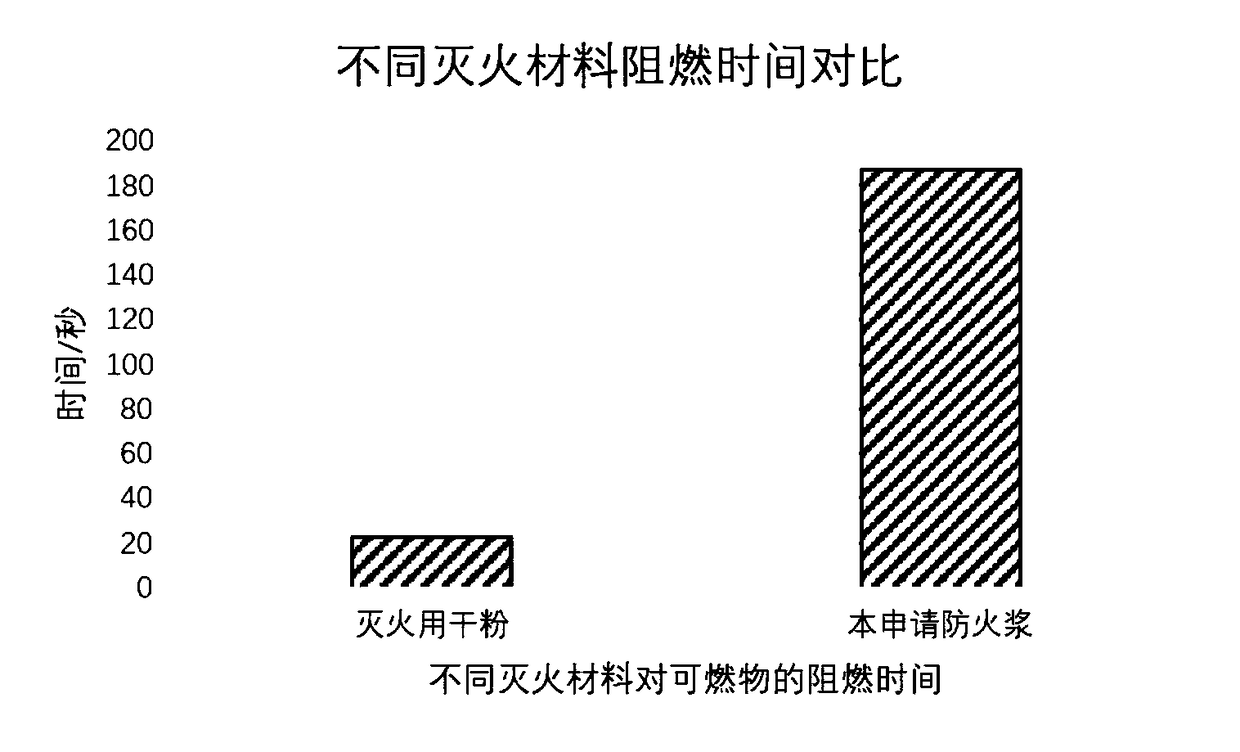

A compound, fire-proof slurry technology, applied in fire-proof coatings, coatings, etc., can solve the problems of short fire-fighting time period, soil pollution, fire source re-ignition, etc., and achieve low cost, simple equipment requirements, and short production cycle Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The present invention provides a preparation method of water-gel composite type fireproof slurry, which is specifically implemented according to the following steps: Step 1, respectively weigh 30-60 parts of water, 10-30 parts of water-soluble ammonium dihydrogen phosphate, and flame-retardant expandable graphite 10-30 parts, 3-8 parts of hydroxyethyl cellulose, 3-8 parts of xanthan gum;

[0031] Step 2, mixing the water-soluble ammonium dihydrogen phosphate weighed in step 1 with expanded graphite, stirring evenly to obtain mixture A;

[0032] Step 3, mix the mixture A obtained in step 2 with the water weighed in step 1, and stir evenly to obtain mixture B;

[0033] Step 4. Mix the mixture B obtained in step 3 with the hydroxyethyl cellulose and xanthan gum weighed in step 1, and stir evenly to obtain a water-gel composite fireproof slurry.

[0034] Ammonium dihydrogen phosphate heating chemical reaction: 2NH 4 h 2 PO 4 =2NH 3 +3H 2 O+P 2 o 5 (heating), the gen...

Embodiment 1

[0042] Step 1. Weigh 30 parts of water, 8 parts of hydroxyethyl cellulose, 3 parts of xanthan gum, 10 parts of water-soluble ammonium dihydrogen phosphate, and 10 parts of flame-retardant expandable graphite in proportion;

[0043] Step 2, mixing the water-soluble ammonium dihydrogen phosphate weighed in step 1 with flame-retardant expandable graphite, and stirring evenly to obtain mixture A;

[0044] Step 3, mix the mixture A obtained in step 2 with the water weighed in step 1, and stir evenly to obtain mixture B;

[0045] Step 4. Mix the mixture B obtained in step 3 with the hydroxyethyl cellulose and xanthan gum weighed in step 1, and stir evenly to obtain a water-gel composite fireproof slurry.

Embodiment 2

[0047] Step 1. Weigh 40 parts of water, 5 parts of hydroxyethyl cellulose, 6 parts of xanthan gum, 20 parts of water-soluble ammonium dihydrogen phosphate, and 20 parts of flame-retardant expandable graphite in proportion;

[0048] Step 2, mixing the water-soluble ammonium dihydrogen phosphate weighed in step 1 with flame-retardant expandable graphite, and stirring evenly to obtain mixture A;

[0049] Step 3, mix the mixture A obtained in step 2 with the water weighed in step 1, and stir evenly to obtain mixture B;

[0050] Step 4. Mix the mixture B obtained in step 3 with the hydroxyethyl cellulose and xanthan gum weighed in step 1, and stir evenly to obtain a water-gel composite fireproof slurry.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com