12-oxystearic acid and boric acid composite lithium prefabricated soap lubricating grease composition and preparation method thereof

A kind of grease composition, hydroxystearic acid technology, applied in the direction of lubricating composition, petroleum industry, thickener, etc., can solve problems such as affecting the life of grease

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

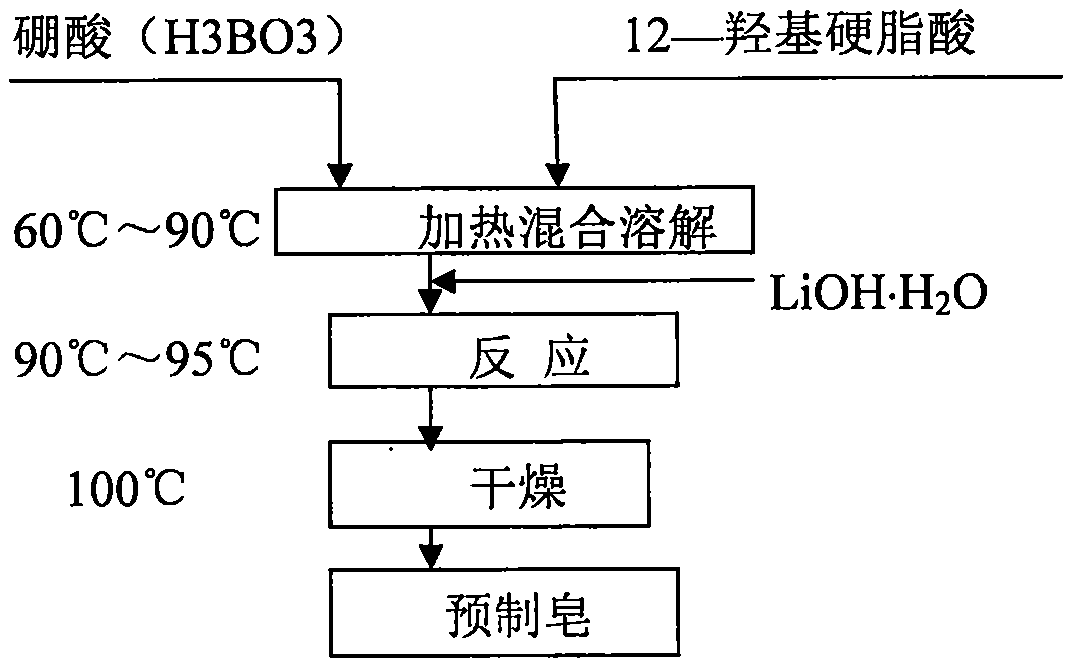

[0034] Embodiment 1: Preparation of lithium boron hydroxy compound prefabricated soap powder

[0035] Add 12.83 grams of 12-hydroxystearic acid and 2.65 grams of boric acid into the container, add 3.6 grams of lithium hydroxide at 60°C to 90°C for reaction, the reaction time is 0.5 hours to 1.5 hours, and the temperature is raised to 90°C to 95°C ℃ drying to obtain boron hydroxy complex lithium prefabricated soap powder.

Embodiment 2

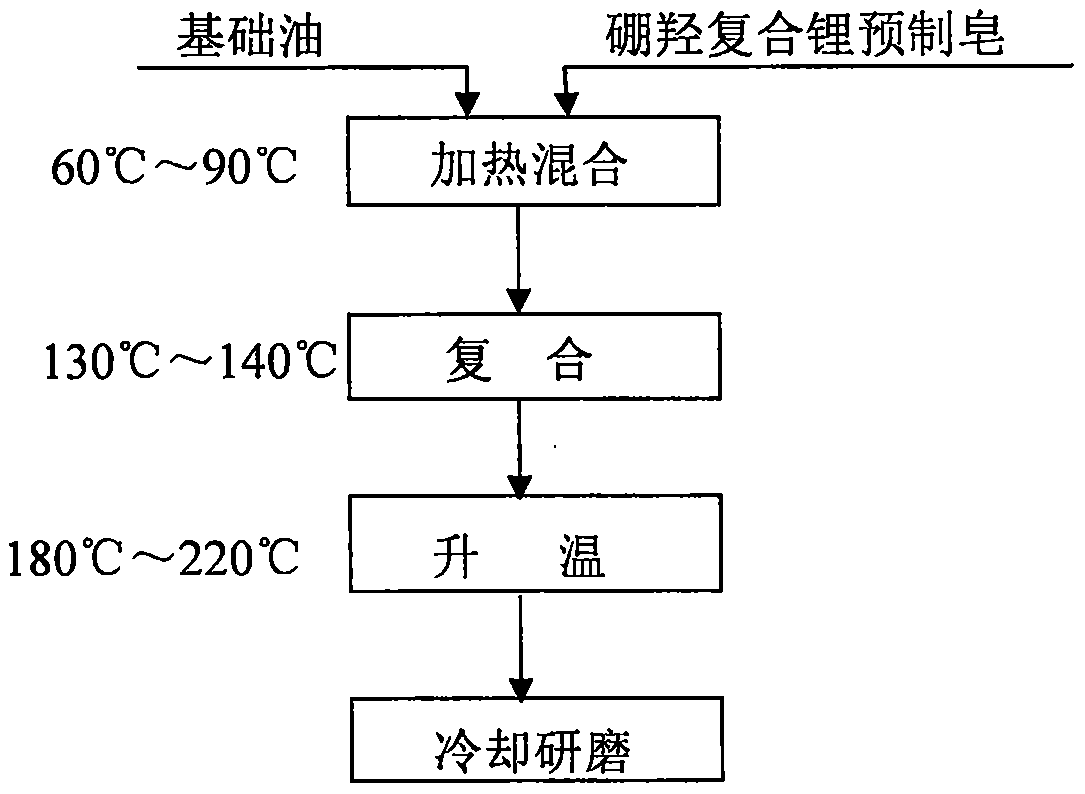

[0036] Embodiment 2: Preparation of grease composition

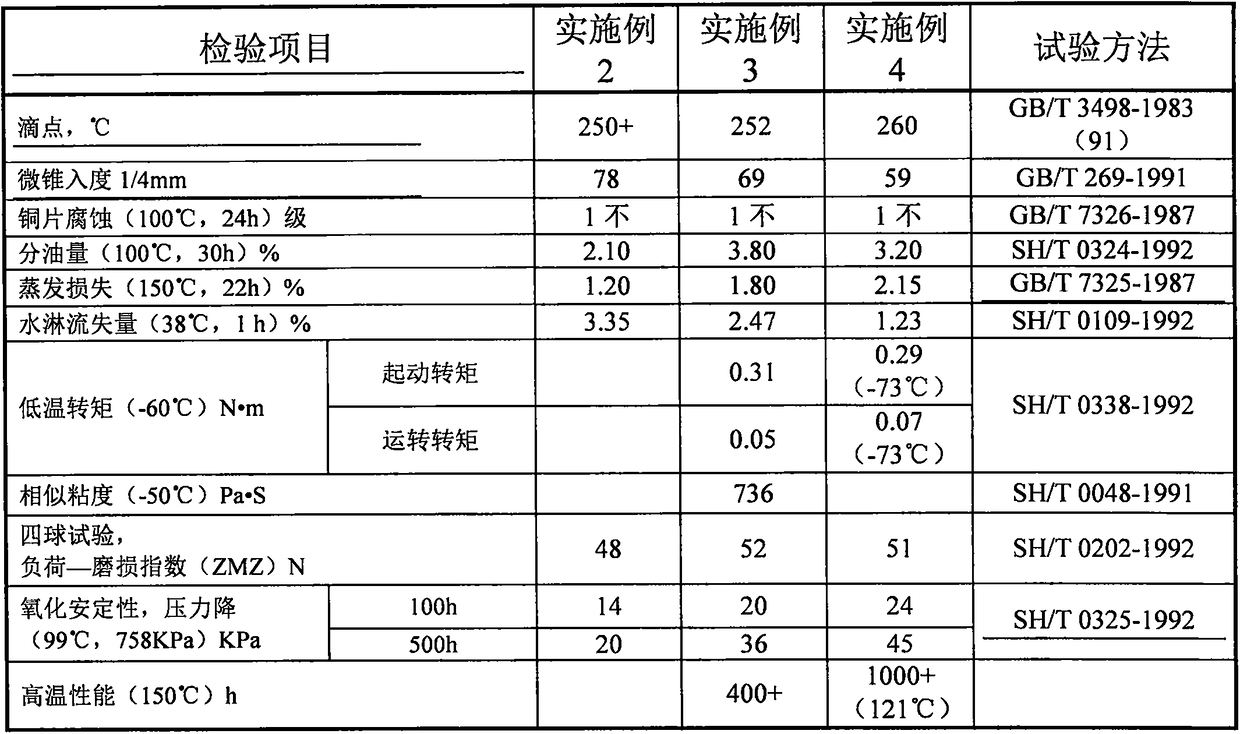

[0037] Add 8 grams of boron hydroxy complex lithium prefabricated soap thickener powder prepared in Example 1 to 92 grams of refined mineral oil (kinematic viscosity: 20 centistokes at 50° C.) at 60° C. to 90° C., stir and mix , heat up to 130°C to 140°C for 1.0 hour to 3.0 hours, continue to heat up to 200°C, cool and homogenize. Obtain the lubricating grease with dropping point > 250°C, stencil oil separation (100°C, 30h) 2.1%, micro-cone penetration 78 at 25°C.

Embodiment 3

[0038] Embodiment 3: preparation lubricating grease composition

[0039] With 15 grams of boron hydroxy complex lithium prefabricated soap thickener powder prepared in Example 1, add 85 grams of synthetic ester oil (wherein kinematic viscosity: be the lubricating oil of 5 centistokes when 50 ℃) at 60 ℃~90 ℃ 25.5 grams, 3 centistoke lubricating oil (59.5 grams), stir and mix, heat up to 130°C-140°C for 1.0 hour-3.0 hours, continue to heat up to 200°C, cool and homogenize. The lubricating grease with a dropping point of 252°C, a stencil oil separation (100°C, 30h) of 3.8%, and a micro-cone penetration of 69 at 25°C was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dropping point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com