Long-acting antistatic nano nylon master batch and preparation method thereof

An antistatic and antistatic agent technology, applied in the field of long-acting antistatic nano-nylon masterbatch and its preparation, can solve problems such as inability to meet requirements, and achieve the effects of large-scale production and application, simple process, excellent opening and smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

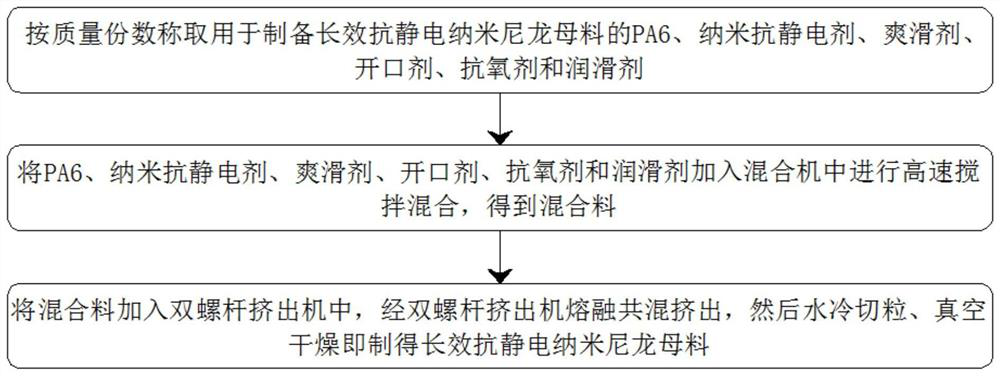

Method used

Image

Examples

Embodiment 1

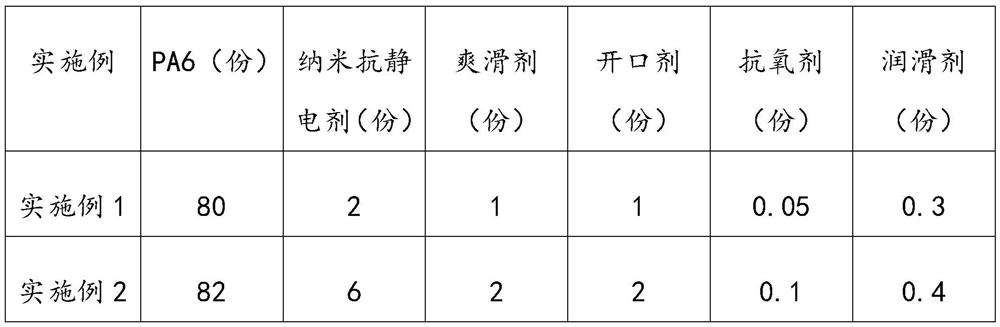

[0025] A long-acting antistatic nano-nylon masterbatch, the formula of the long-acting antistatic nano-nylon masterbatch in parts by mass is as follows:

[0026] 80 parts of PA6, 5 parts of nano antistatic agent, 1 part of slippery agent, 1 part of opening agent, 0.05 part of antioxidant and 0.3 part of lubricant.

[0027] Among them, PA6 is medium-viscosity PA6, the nano-antistatic agent is nano-silica, the slippery agent is erucamide, the opening agent is fumed silica, and the antioxidant is β-(3,5-di-tert-butyl- A composition of 4-hydroxyphenyl) n-octadecanyl propionate and tris [2,4-di-tert-butylphenyl] phosphite, and the mass ratio is 2:3, and the lubricant is polysiloxane .

[0028] A kind of preparation method of long-acting antistatic nano-nylon masterbatch, comprises the steps:

[0029] S1. Take PA6, nanometer antistatic agent, slippery agent, blocking agent, antioxidant and lubricant for preparing long-acting antistatic nanometer nylon masterbatch by mass parts;

...

Embodiment 2

[0034] A long-acting antistatic nano-nylon masterbatch, the formula of the long-acting antistatic nano-nylon masterbatch in parts by mass is as follows:

[0035] 82 parts of PA6, 6 parts of nano antistatic agent, 2 parts of slippery agent, 2 parts of opening agent, 0.1 part of antioxidant and 0.4 part of lubricant.

[0036] Among them, PA6 is low-viscosity PA6, the nano-antistatic agent is nano-silicon oxide, the slip agent is a composition of erucamide and oleic acid amide, and the mass ratio is 1:2, the anti-blocking agent is precipitated silica, anti-static The oxygen agent is antioxidant ST-181A, the lubricant is a composition of silicone powder and erucamide, and the mass ratio is 5:2.

[0037] A kind of preparation method of long-acting antistatic nano-nylon masterbatch, comprises the steps:

[0038] S1. Take PA6, nanometer antistatic agent, slippery agent, blocking agent, antioxidant and lubricant for preparing long-acting antistatic nanometer nylon masterbatch by mass...

Embodiment 3

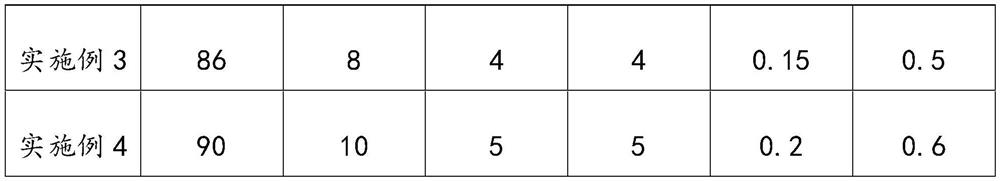

[0043] A long-acting antistatic nano-nylon masterbatch, the formula of the long-acting antistatic nano-nylon masterbatch in parts by mass is as follows:

[0044] 86 parts of PA6, 8 parts of nano antistatic agent, 4 parts of slippery agent, 4 parts of opening agent, 0.15 part of antioxidant and 0.5 part of lubricant.

[0045] Among them, PA6 is a composition of medium-viscosity PA6 and low-viscosity PA6, and the mass ratio is 1:4, the nano-antistatic agent is nano-silicon oxide, and the smoothing agent is a composition of oleic acid amide and ethylene bis-stearamide. And the mass ratio is 1:3, the blocking agent is a composition of fumed silica and precipitated silica, and the mass ratio is 1:1, the antioxidant is potassium iodide, and the lubricant is erucamide.

[0046] A kind of preparation method of long-acting antistatic nano-nylon masterbatch, comprises the steps:

[0047] S1. Take PA6, nanometer antistatic agent, slippery agent, blocking agent, antioxidant and lubricant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com