Skirt separation plate underground diaphragm wall-pile combined foundation

An underground continuous wall, composite technology, applied in sheet pile walls, infrastructure engineering, construction, etc., can solve the problems of insufficient resistance to horizontal loads, stress concentration at connection points, low stiffness of suction buckets, etc., to improve the horizontal bearing capacity. capacity, the overall structure is reasonably stressed, and the effect of increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings and technical solutions.

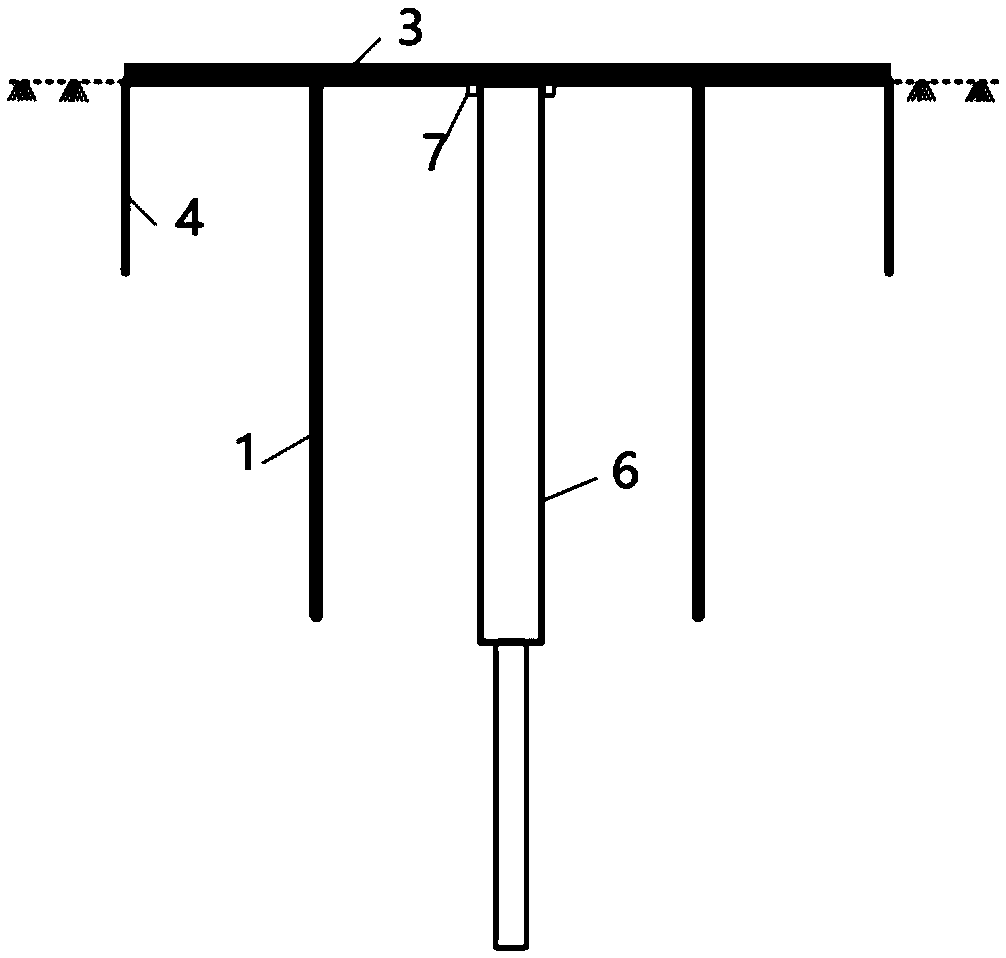

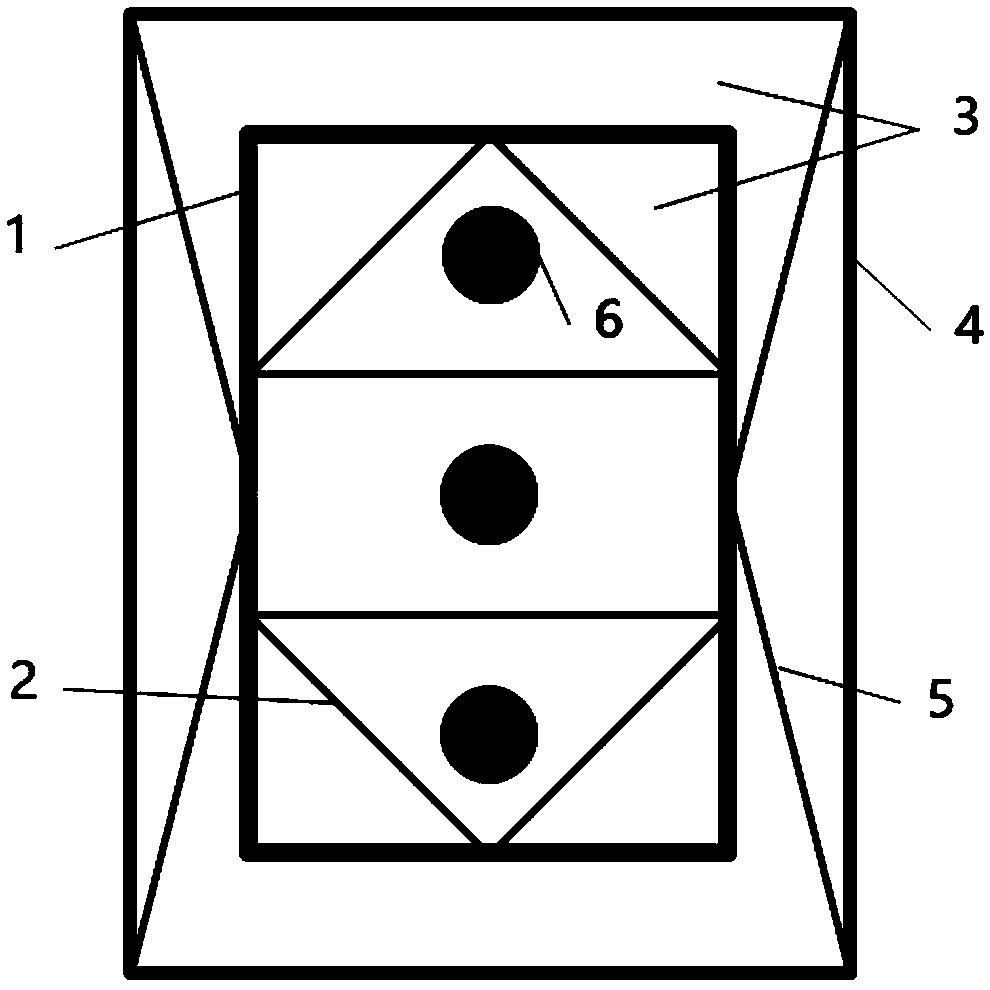

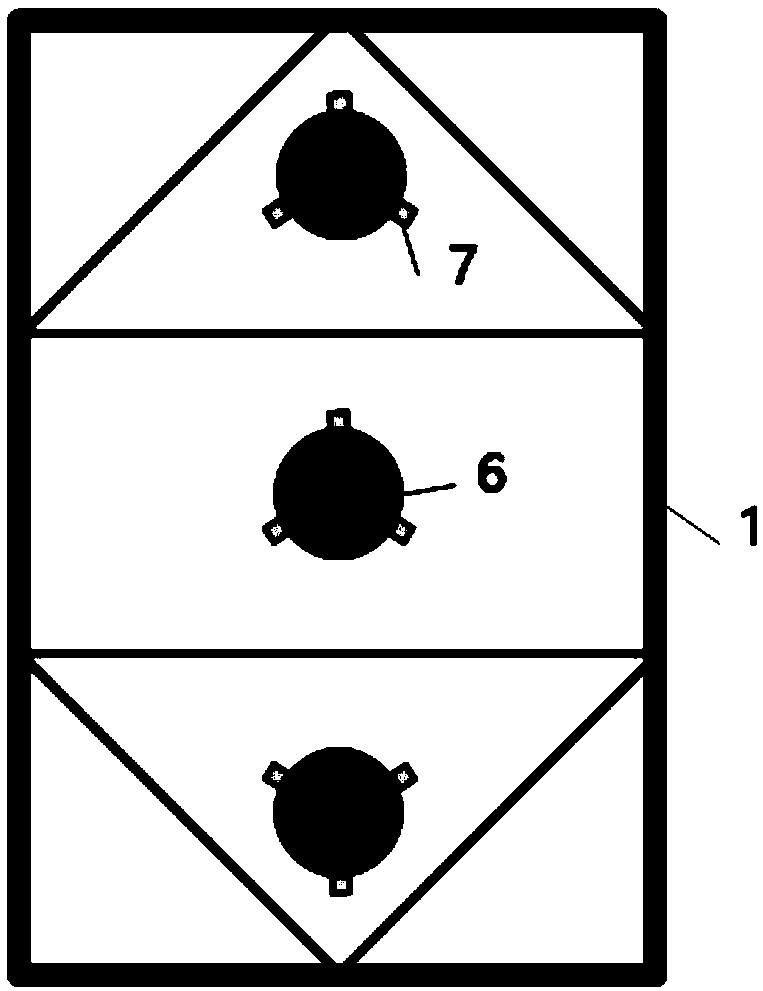

[0028] A kind of skirt-type underground diaphragm wall-pile composite foundation, such as figure 1 and figure 2 As shown, the materials selected in the present invention are steel plates and concrete materials, which mainly include the main underground continuous wall 1, the cap plate 3, the skirt structure 4 and the pile 6. And the main underground diaphragm wall 1 is connected with the skirt type underground diaphragm wall 4 through the external vertical partition 5, and the main underground diaphragm wall 1 divides the internal space into several independent small spaces through the internal vertical partition 2, and three variable-section piles 6 is filled in the independent small space, and the main underground diaphragm wall 1, skirt-type underground diaphragm wall 4 and piles 6 connect the three in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com