Template construction method capable of preventing wall of underground concrete pool from seepage

A construction method and anti-leakage technology, applied to artificial islands, water conservancy projects, underwater structures, etc., can solve the problems of loose formwork joints, high cost, troublesome treatment and repair, etc., to reduce construction costs and shorten construction The construction period and the effect of improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the examples, the purpose is only to better understand the contents of the present invention, therefore, the examples given do not limit the protection scope of the present invention.

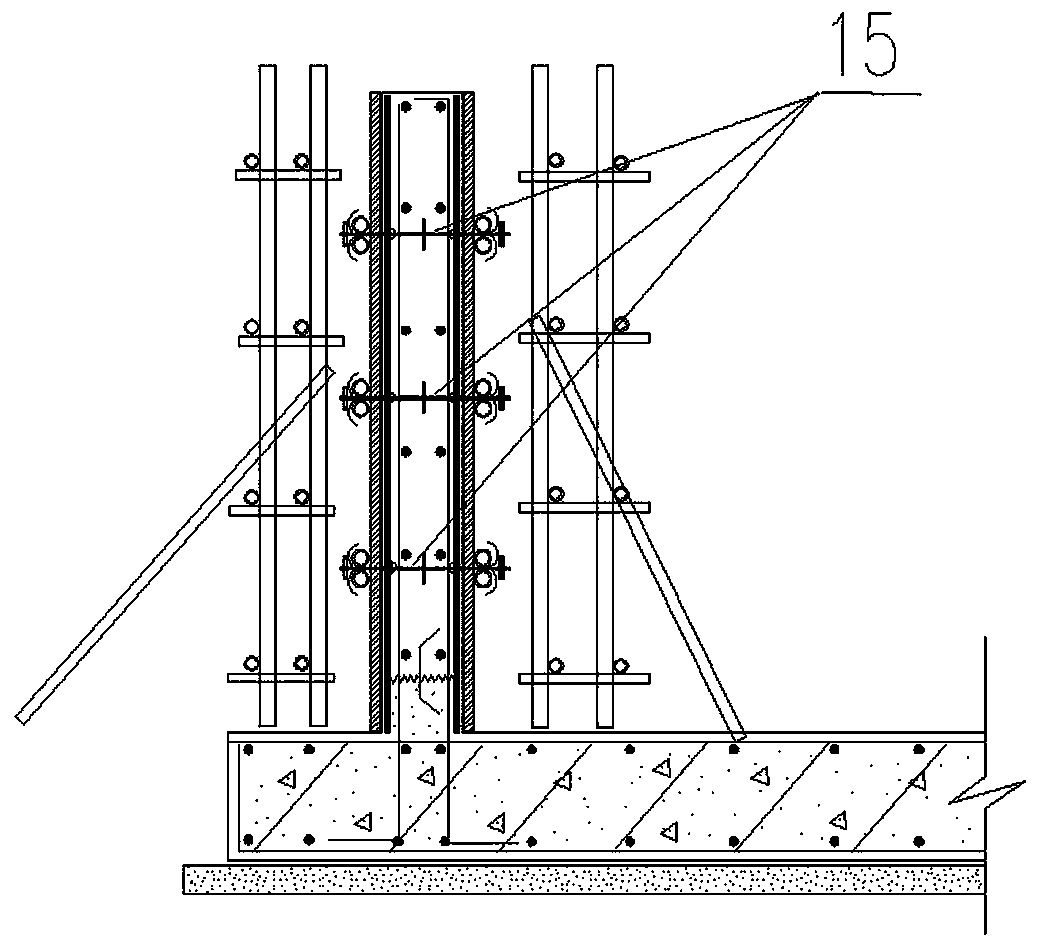

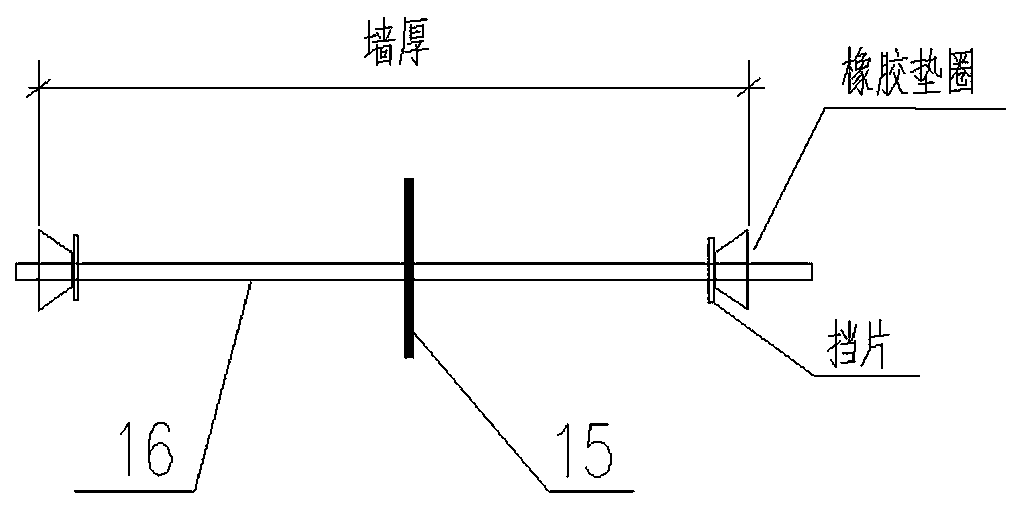

[0032] see figure 1 , figure 2 , the template support of the pool wall 3 in the prior art is to weld the waterproof steel plate 16 through the middle of the tie bolt rod 15 .

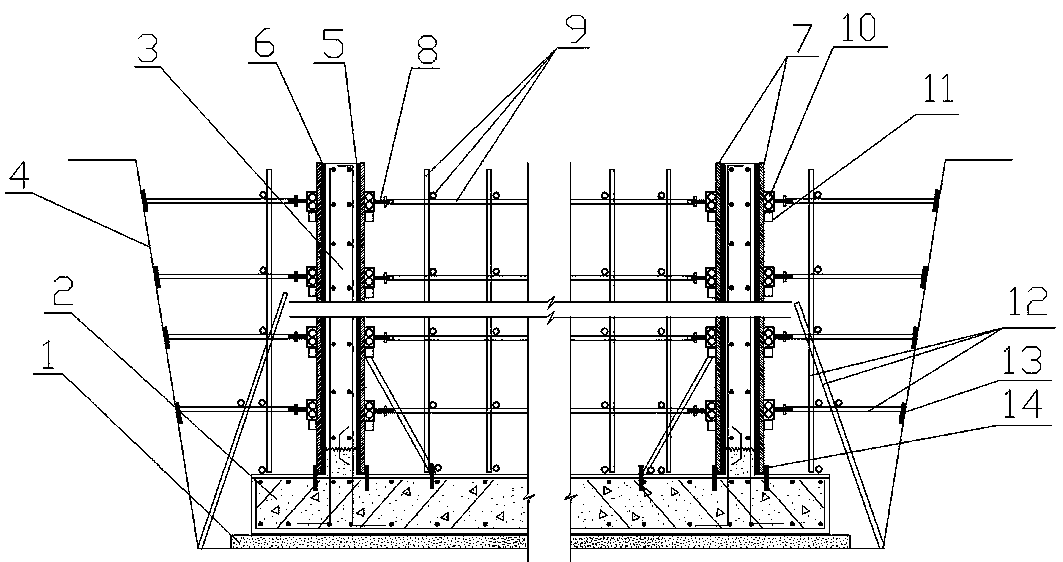

[0033] see image 3 , a formwork construction method for anti-seepage of underground concrete pool walls, comprising the steps of:

[0034] The first step, earthwork excavation of the foundation pit structure:

[0035] According to the geological conditions, excavate the foundation pit according to the approved earthwork excavation plan, and do a good job in the protection of the side slope 4.

[0036] The second step, concrete pouring of pool bottom plate 2:

[0037] The bottom plate of the pool 2 is bound to formwork, and concrete is...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap