Water pump with double water outlets

A dual water outlet and water pump technology, applied in the direction of pumps, pump devices, pump components, etc., can solve the problems of increasing product volume and cost, only one liquid medium can be pumped, and uneven bearing force, etc., to increase practicability. , The bearing wear is small, and the effect of reducing friction noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

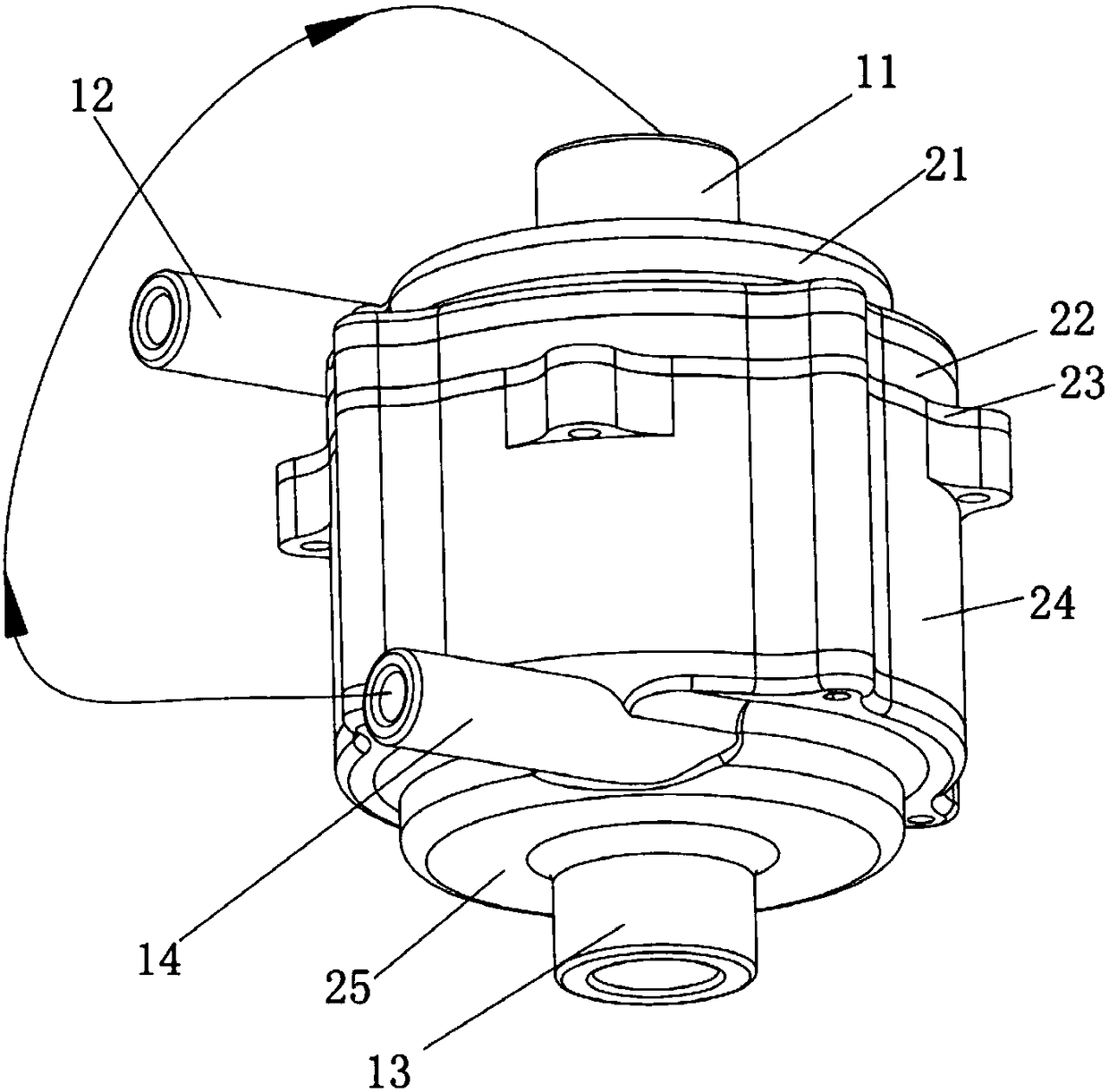

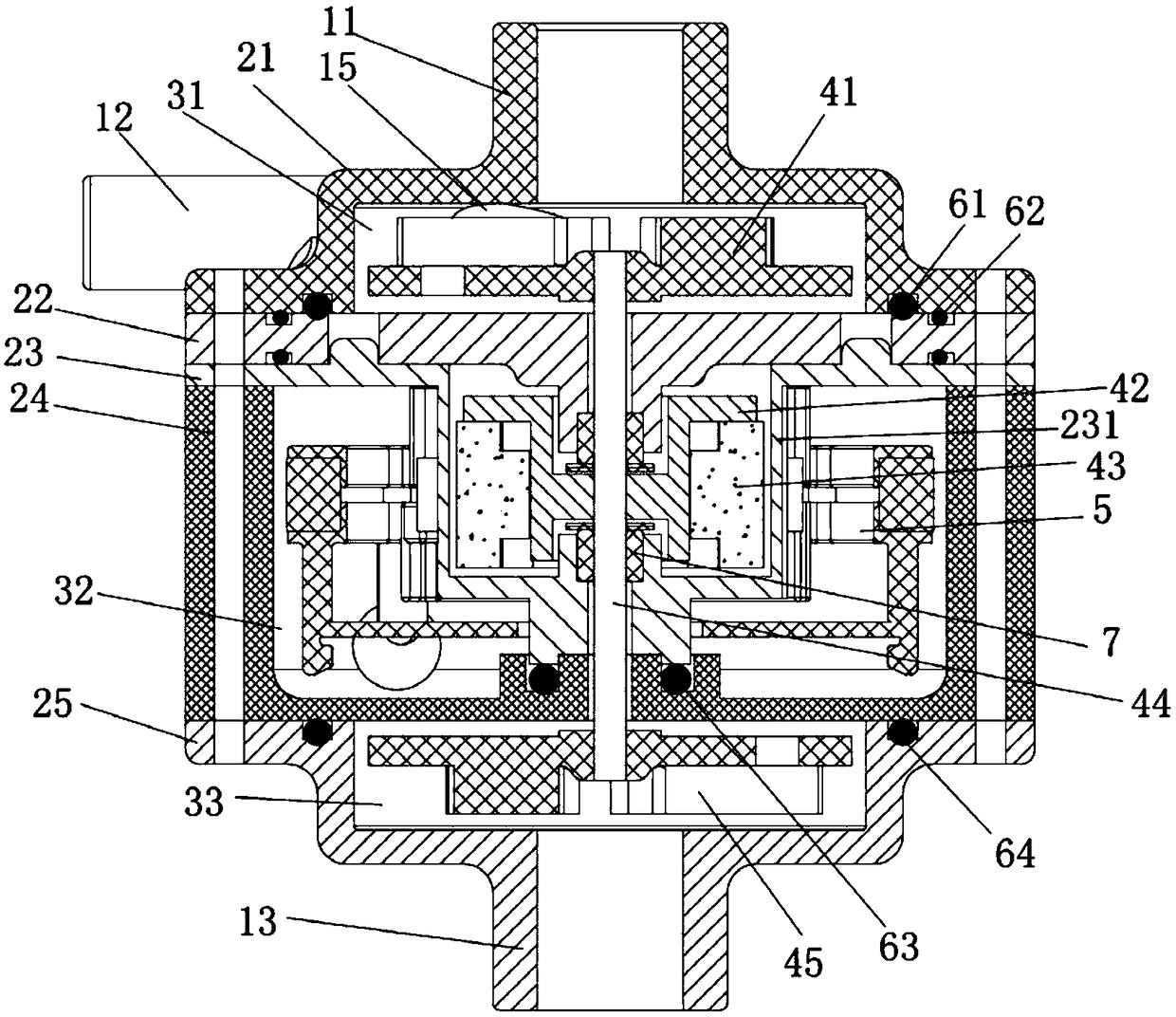

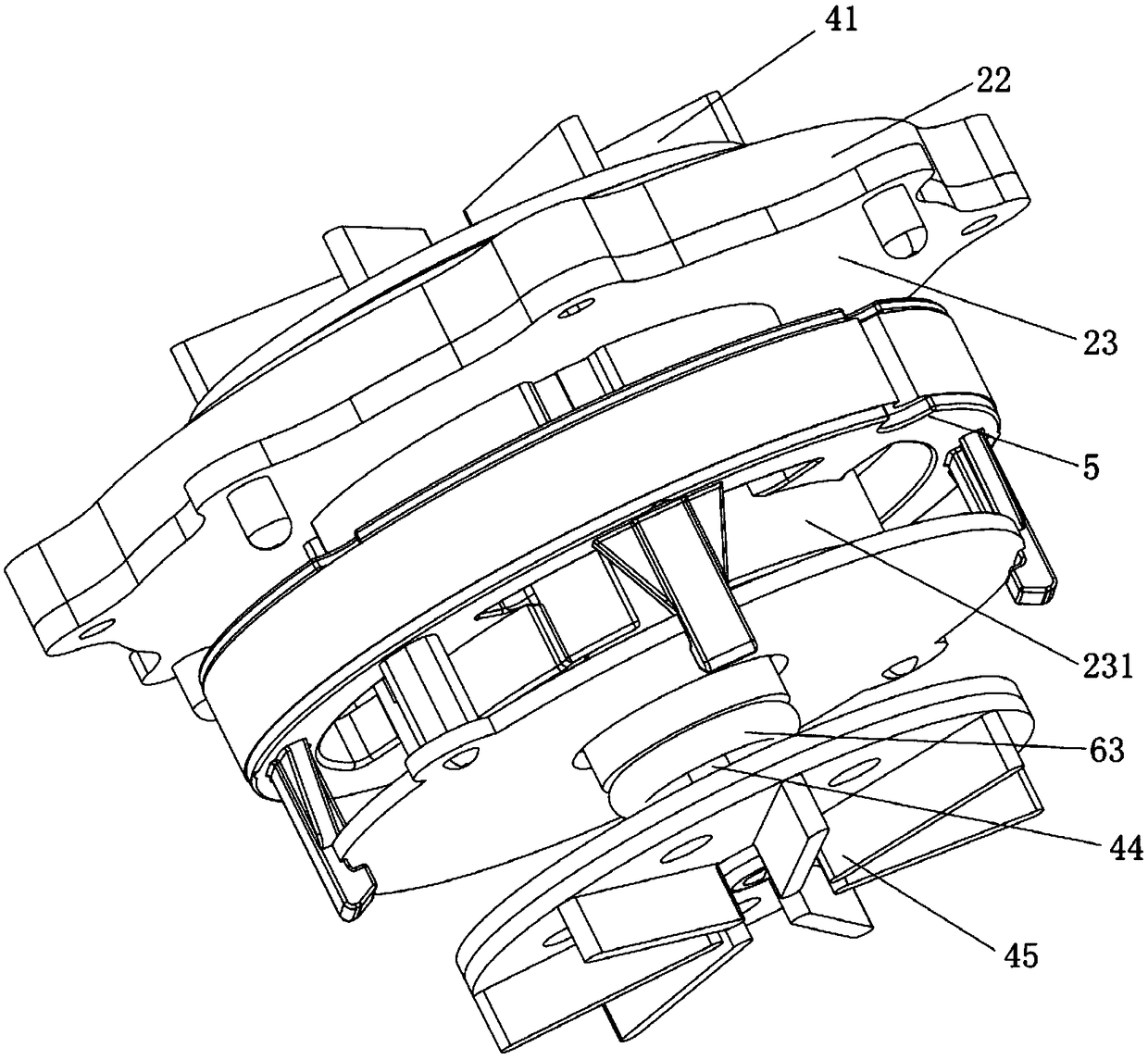

[0023] Such as Figure 1-3 As shown, a water pump with double water outlets includes a first side cover 21, a sealing plate 22, a middle plate 23, a casing 24 and a second side cover 25 arranged in sequence, and the first side cover 21 and the sealing plate 22 form a second A pump chamber 31, a second pump chamber 33 is formed between the second side cover 25 and the casing 24, an installation cavity 32 is formed between the casing 24 and the middle plate 23, and the stator 5, the middle plate 23 and the seal are arranged in the installation cavity 32 A rotor cooperating with the stator 5 is arranged between the plates 22. A main shaft 44 is arranged at the center of the rotor, and the two ends of the main shaft 44 extend toward the first pump chamber 31 and the second pump chamber 33. 31. The second pump chamber 33 is respectively provided with impellers, the first pump chamber 31 is provided with a first impeller 41, the second pump chamber 33 is provided with a second impel...

Embodiment 2

[0035] like figure 1 As shown, the difference from the technical solution of the first embodiment above is that the first water inlet pipe is connected to the second water outlet pipe through a conduit (or the first water outlet pipe is connected to the second water inlet pipe through a conduit) to connect the first pump chamber and the second water outlet pipe. The second pump chamber communicates and forms a pumping passage with a long lift, which improves the lift of the water pump and the flow rate of the pumped liquid.

[0036] After the stator 5 of the present invention is energized, the rotor starts to drive the main shaft 44 to rotate, and the two ends of the main shaft 44 drive the impeller to rotate. When the impeller rotates, a vortex will be formed in the first pump chamber and the second pump chamber to generate pressure, and the liquid will pass through the first water inlet pipe 11 Enter the first pump chamber, and then pump the liquid from the first water outle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com