Thermoplastic composite laminated body

A composite layer and thermoplastic technology, applied in the direction of shock absorbers, engine frames, springs/shock absorbers, etc., can solve the problems of inability to adjust the distance between layers and the inability to complete the composite layer, and achieve weighing capacity and Enhanced compression resistance, stable heat dissipation, and improved strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

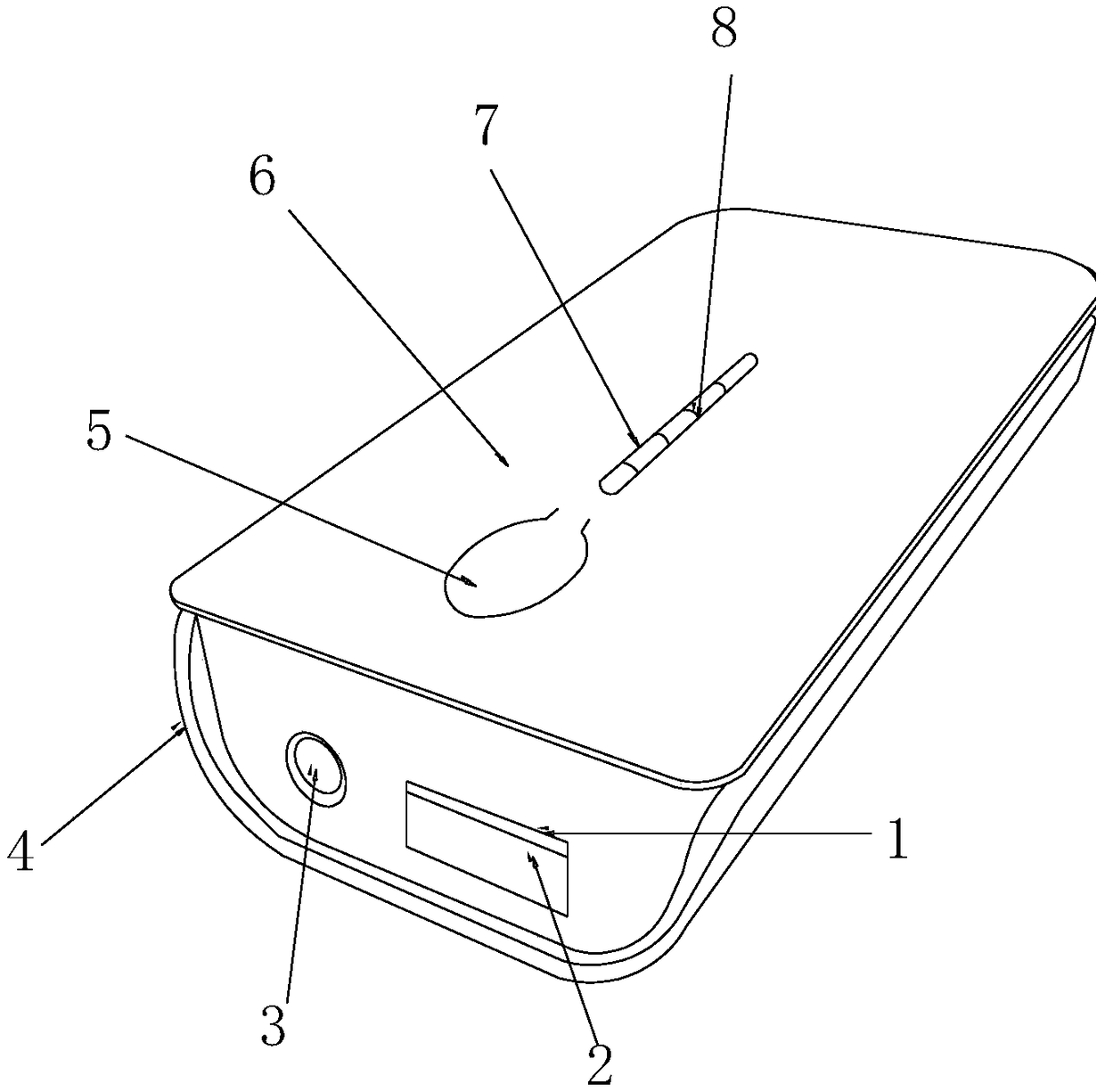

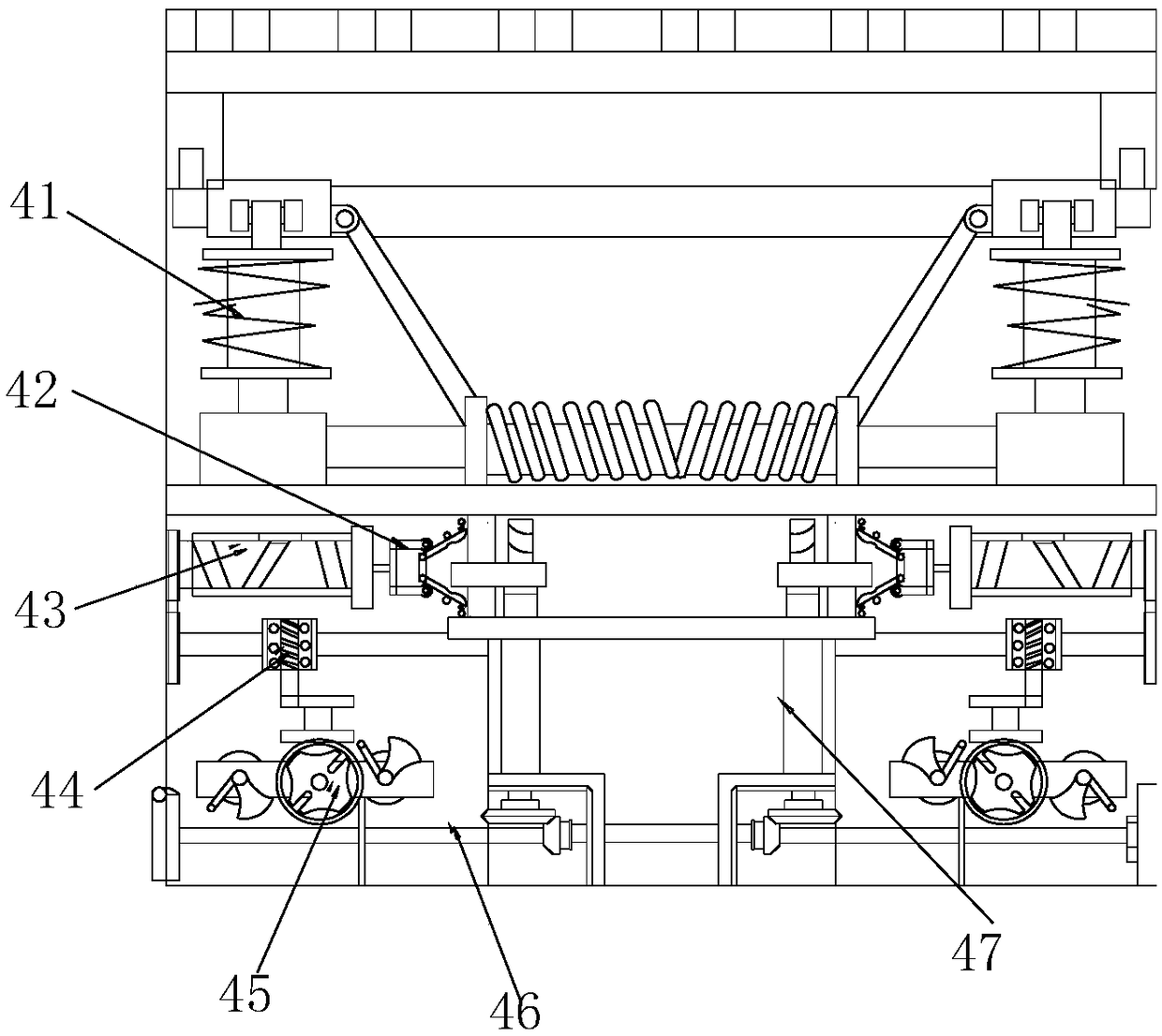

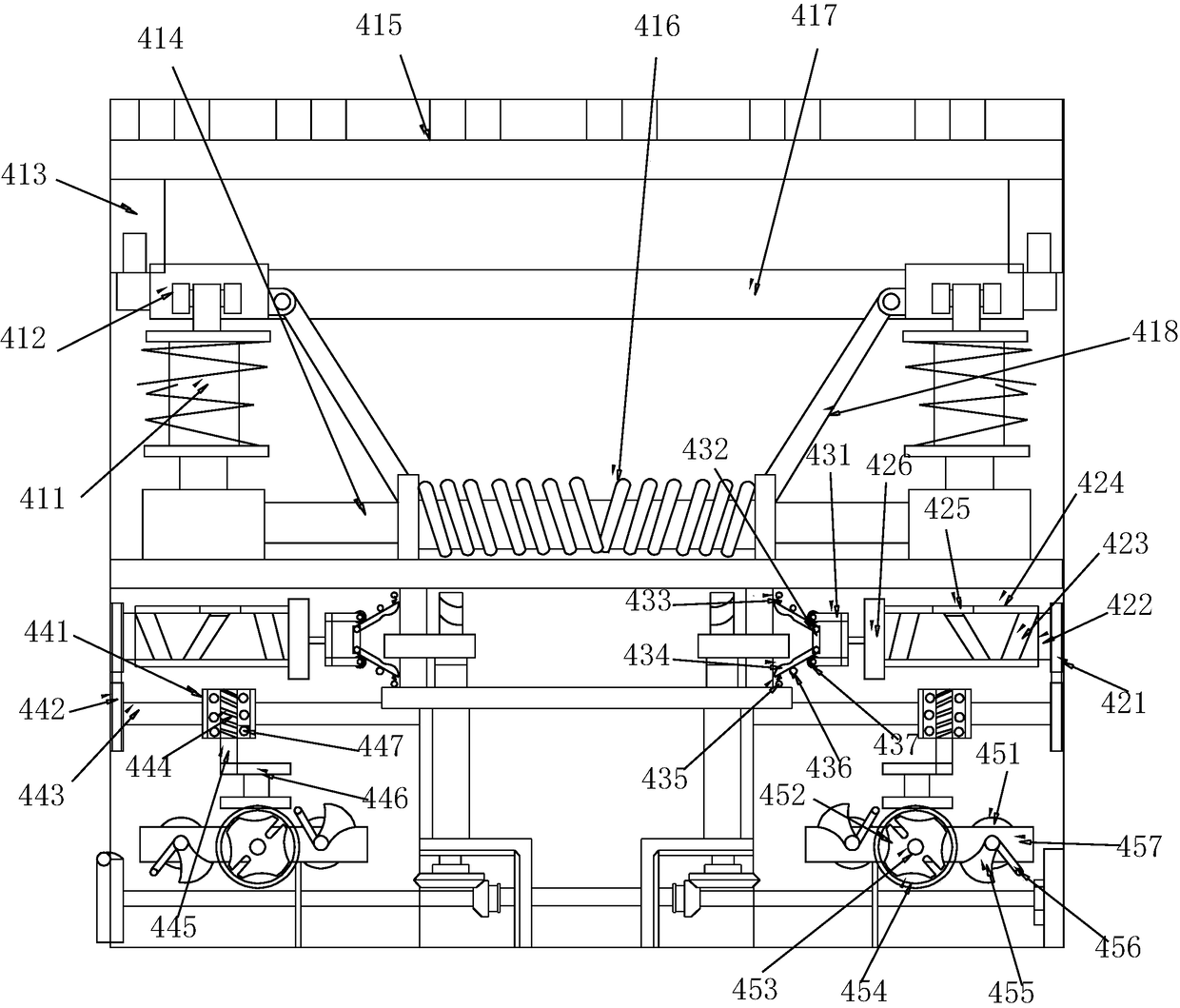

[0029] see Figure 1-Figure 5 , the present invention provides a thermoplastic composite laminate, the structure of which includes: a movable frame 1, a through-hole frame 2, a mechanical frame 3, an intelligent movable control composite device 4, a movable plate 5, a device housing 6, a chute frame 7, and a hook frame 8. The device housing 6 is located on the upper surface of the intelligent activity control composite device 4. The two form an integrated structure by welding. The movable plate 5 is arranged on the upper surface of the device housing 5 and is connected to the device housing. 5 is an integrated structure, the chute frame 7 is arranged on the upper side surface of the device housing 6 and both are fixedly connected to form a structure, and the hook frame 8 is arranged on the inner surface of the chute frame 7 to cooperate with each other. Connected together, the mechanical frame 3 is arranged on the front surface of the intelligent activity control composite dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com