Flue gas waste heat recovery and utilization method

A technology of flue gas waste heat and recovery device, applied in heat exchangers, heat exchange equipment, heat exchanger types, etc., can solve the problems of exhaust gas loss, waste of resources, low thermal efficiency of boilers, etc., to achieve a high degree of automation and cost savings Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following is further described in detail through specific implementation methods:

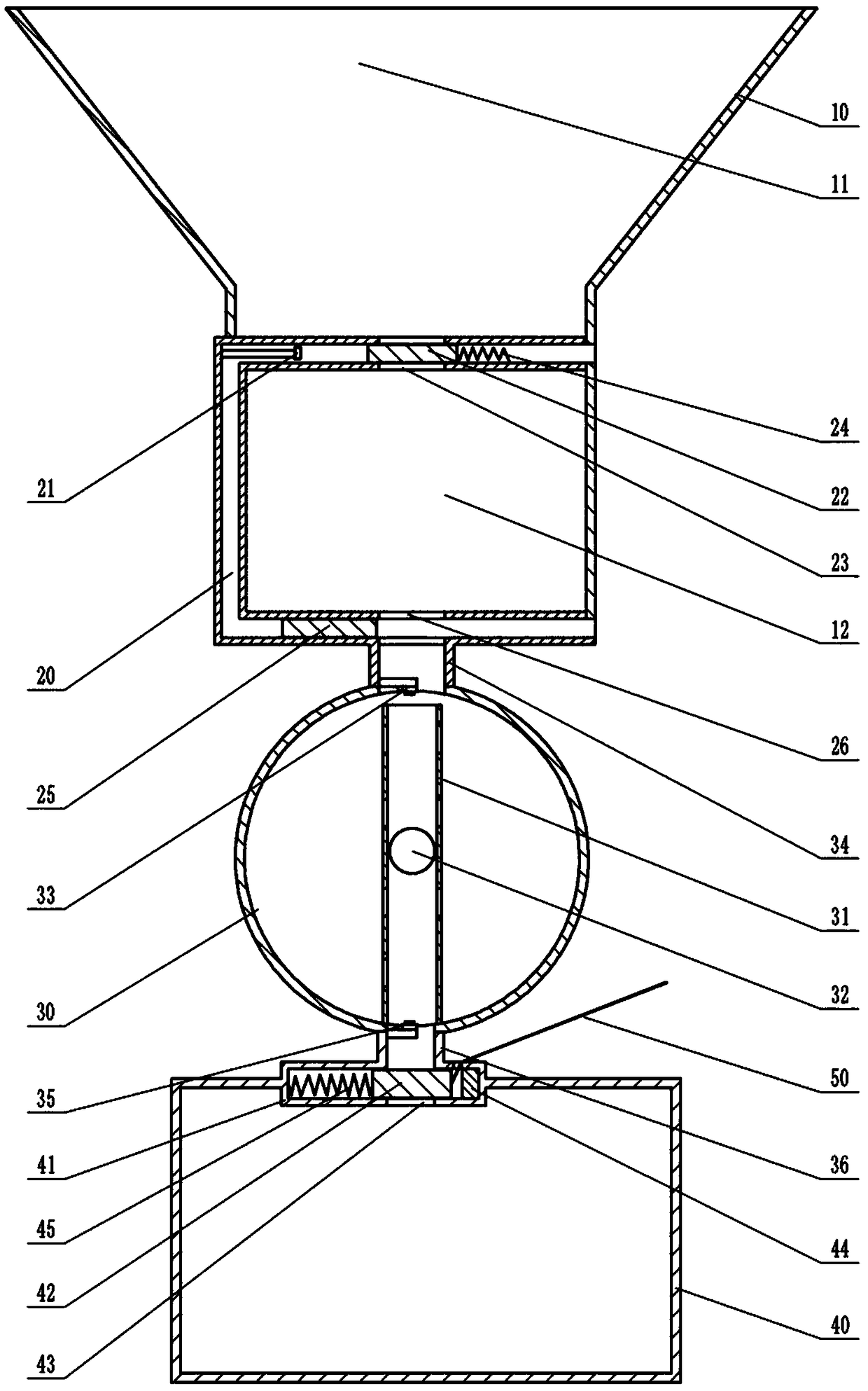

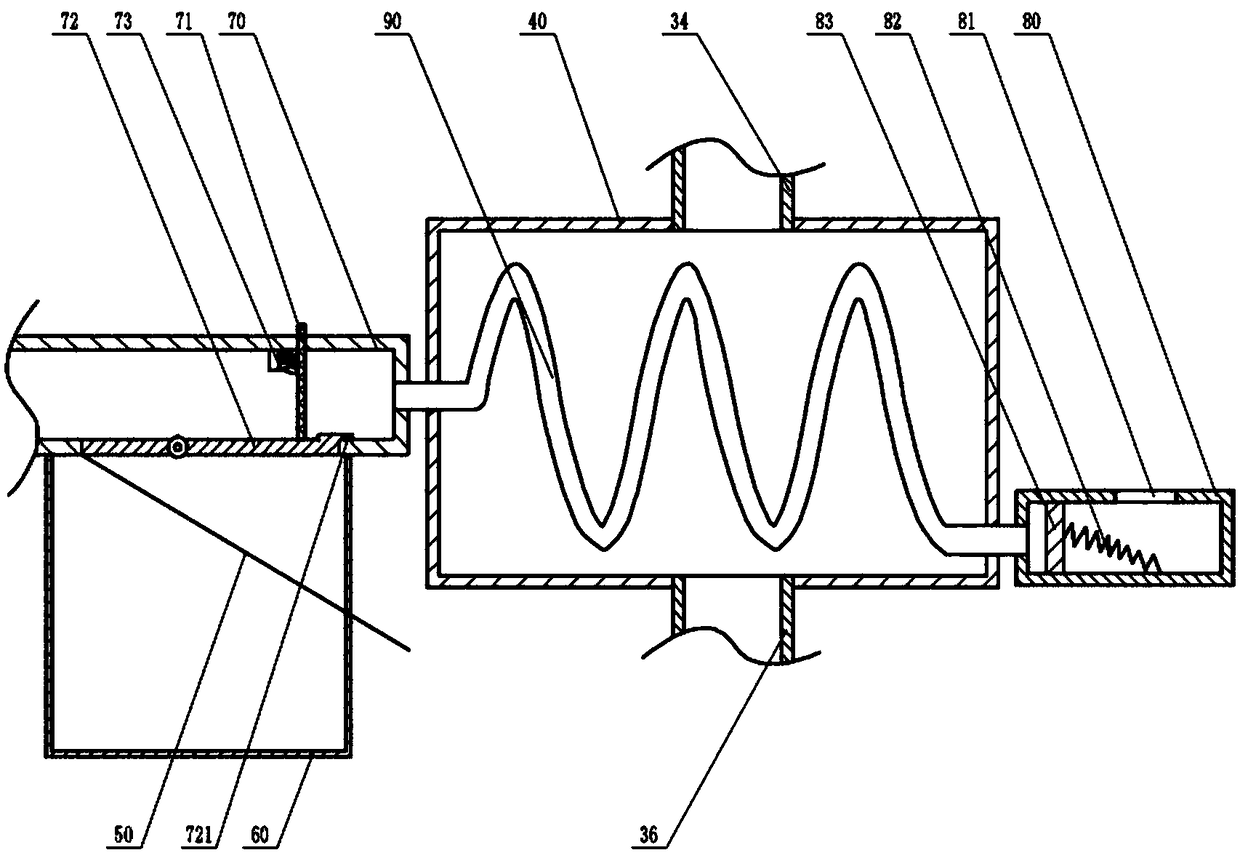

[0023] Instructions attached Figures 1 to 2 The reference signs in include: water storage tank 10, upper chamber 11, lower chamber 12, communicating pipe 20, second electromagnet 21, magnet 22, first port 23, first spring 24, slider 25, second port Port 26, heating cylinder 30, limit frame 31, floating ball 32, first single-control switch 33, first pipe 34, second single-control switch 35, second pipe 36, heat preservation water tank 40, fixed block 41, magnetic strip 42. Through hole 43, first electromagnet 44, tension spring 45, pull wire 50, dust box 60, straight line part 70, screen 71, flip plate 72, protrusion 721, brush handle 73, buffer channel 80, exhaust Port 81, second spring 82, piston 83, spiral part 90.

[0024] Such as figure 1 , figure 2 As shown, the flue gas waste heat recovery method uses a flue gas waste heat recovery device for waste heat recovery. The flue...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com