Water-cooling temperature sensor and assembling method thereof

A temperature sensor and water-cooling technology, applied in the field of sensors, can solve the problems of adapting to the sensor assembly environment, affecting the service life of the product, and causing great damage to the product, achieving the effects of simple and fast assembly, high production efficiency, and fewer installation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

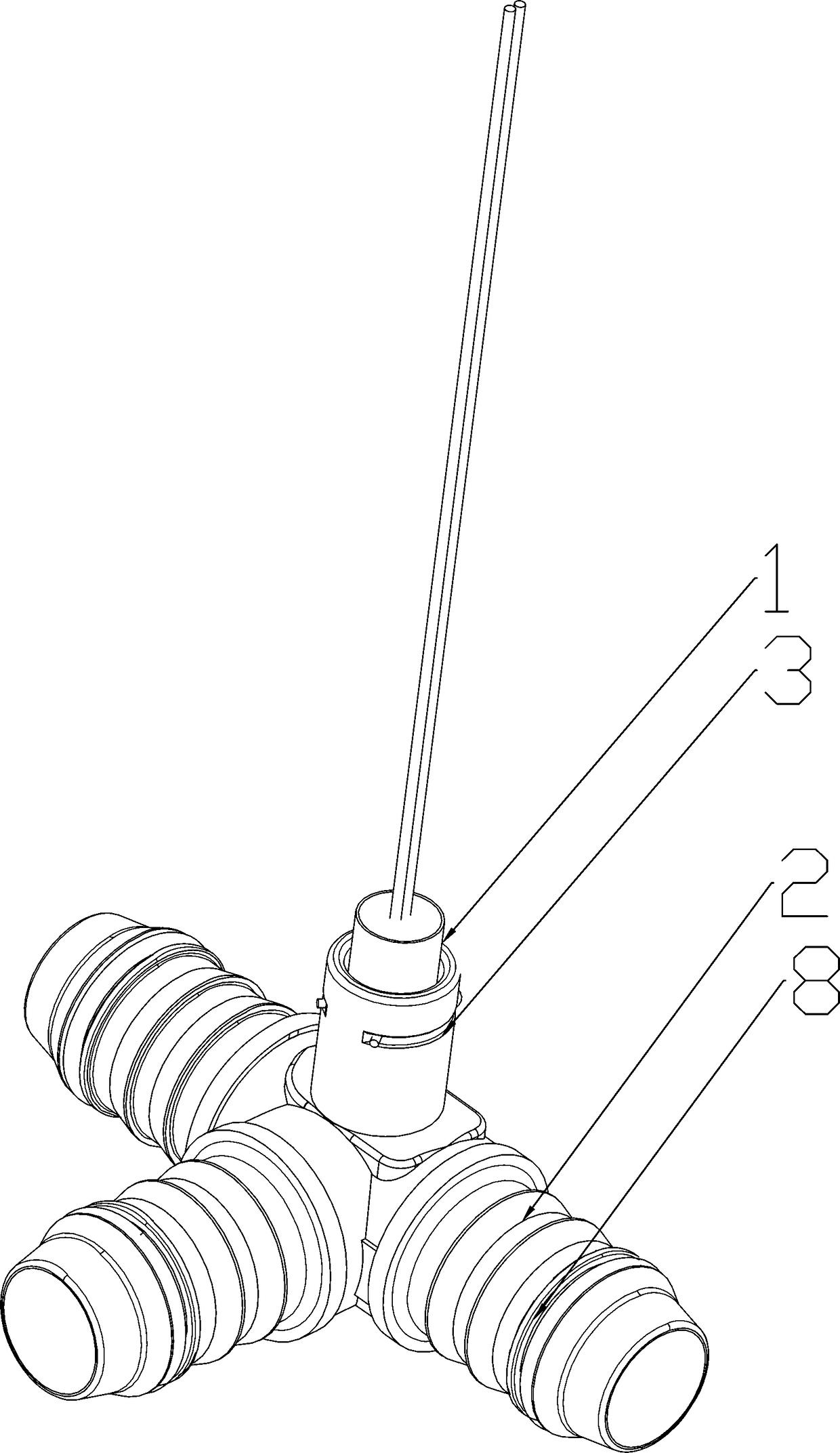

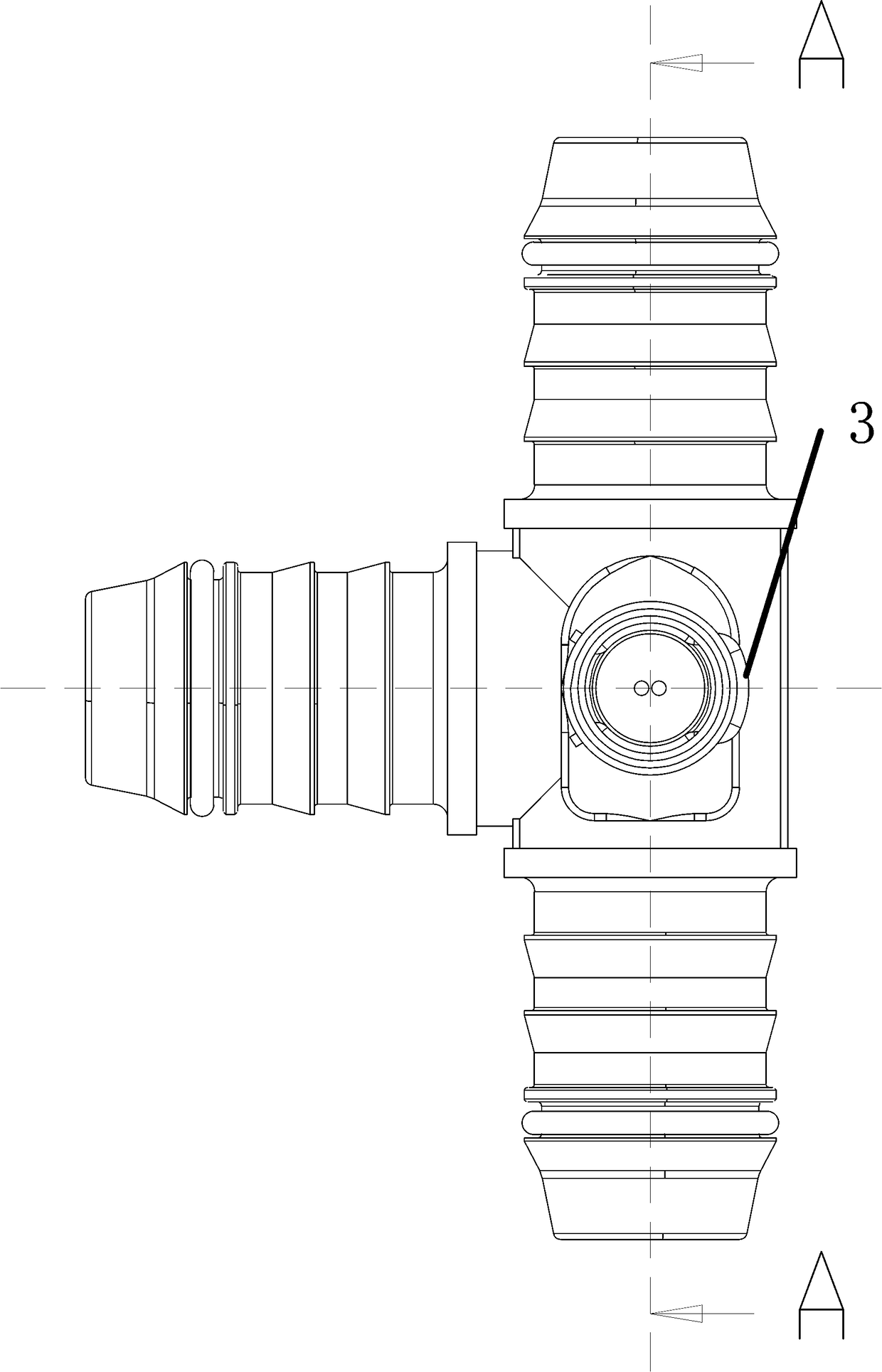

[0027] Such as Figure 1-4 As shown, a water-cooled temperature sensor includes an NTC component 1 and a water pipe joint 2.

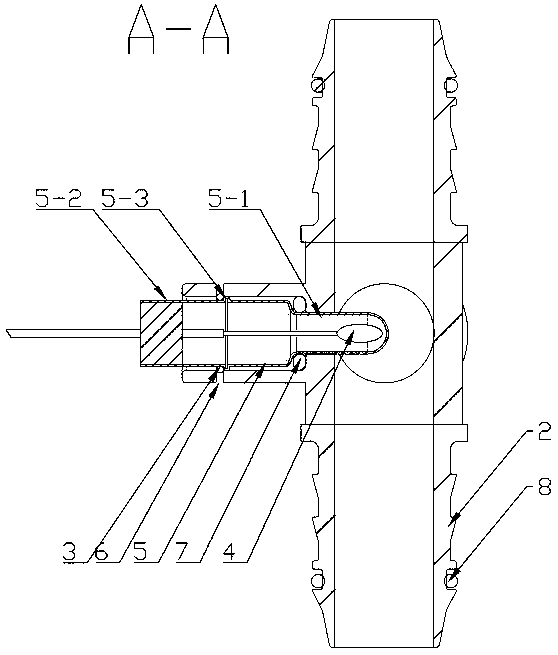

[0028] The NTC assembly 1 is assembled by a metal tube 5 and an NTC thermistor 4. The metal tube 5 is a steel tube, including a head 5-1 and a tail 5-2. The diameter of the head 5-1 is smaller than that of the tail 5-2. After the NTC thermistor 4 is loaded into the metal tube 5, the tail part 5-2 is fixed with a sealing cap or glue.

[0029] The water pipe joint 2 is injection molded, and can be a three-way water pipe joint or a two-way water pipe joint. A base is provided at the upper end of the water pipe joint, and a counterbore for the NTC component 1 to pass through is provided on the base, and the counterbore is communicated with the water pipe joint 2 inside. The head 5-1 of the NTC assembly 1 passes through the counterbore and partially extends into the water pipe joint 2, and the transition between the head 5-1 and the tail 5-2 is covered wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com