Pipe gallery joint waterproofness test method

A test method and technology for pipe gallery joints, applied in the direction of pipes/pipe joints/fittings, testing of fluid tightness, testing of machines/structural components, etc., can solve the problem of inability to simulate pipe gallery, limited scope of application, and cumbersome test steps and other problems to achieve the effect of avoiding the inability to increase the water pressure, improving the test efficiency, and shortening the time required for the test

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

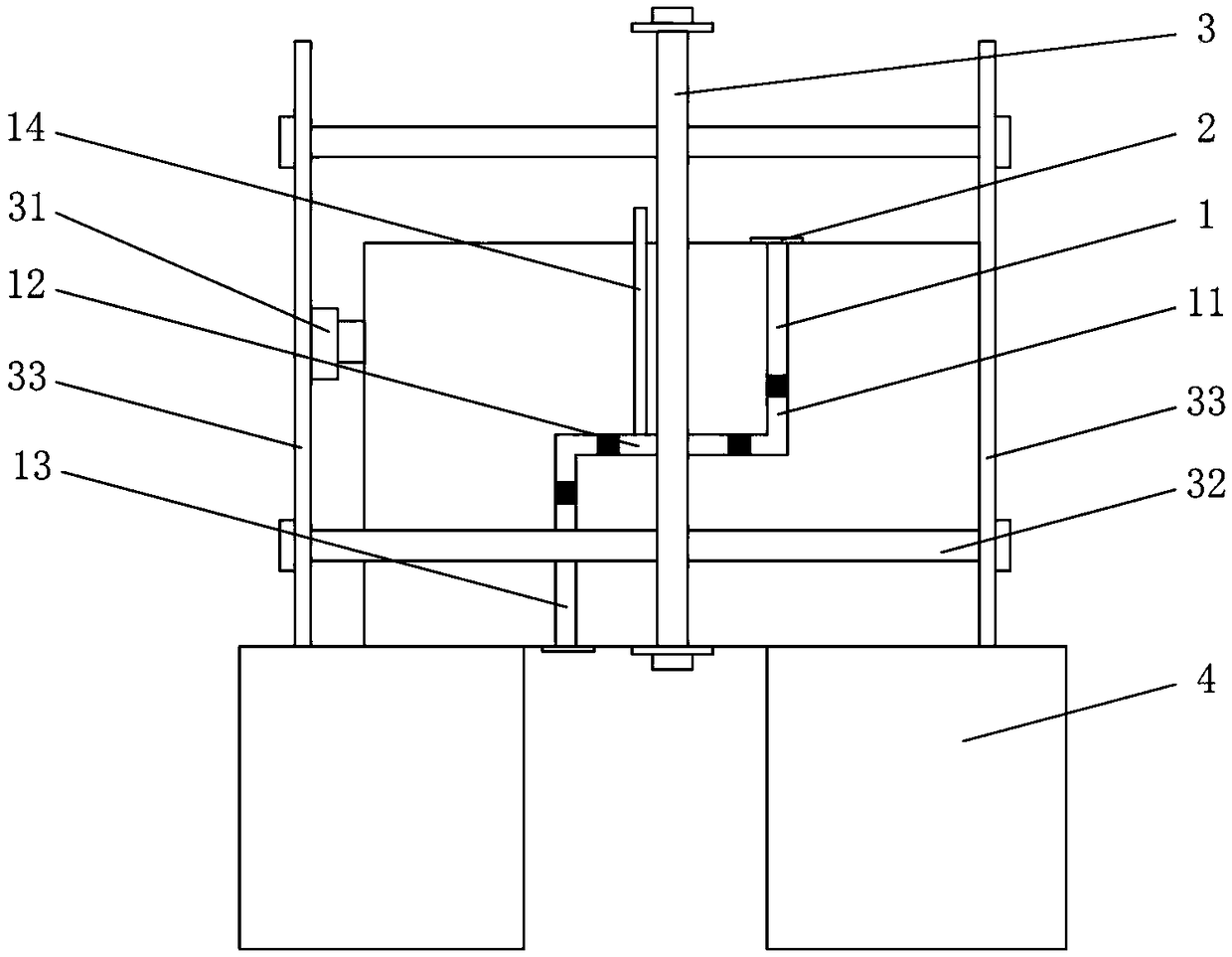

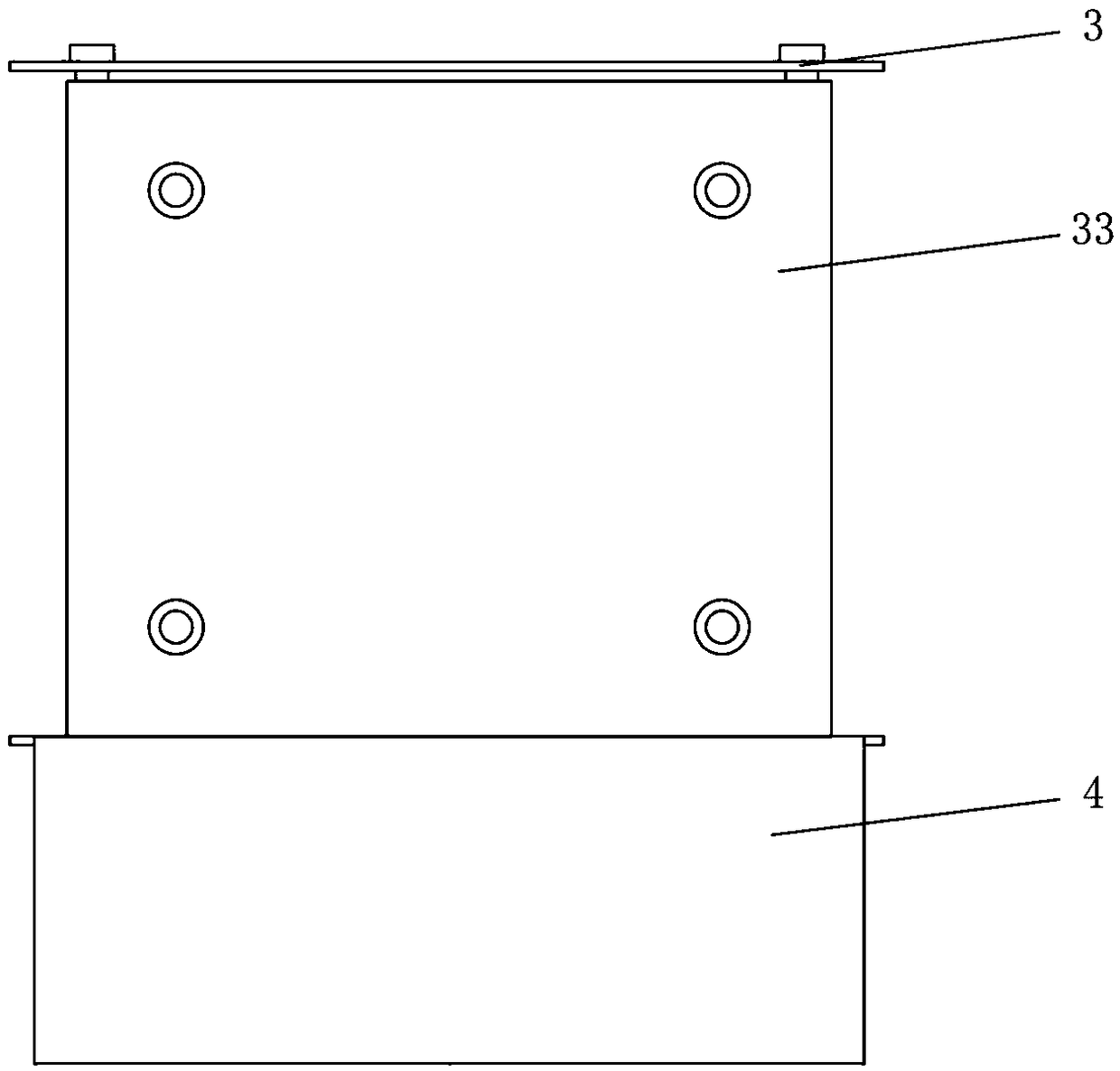

[0030] Such as figure 1 As shown, in the waterproof test method for pipe gallery joints in this embodiment, the pipe gallery is a plug-in type pipe gallery, and its butt joint 1 is a labyrinth joint, including a first radial joint 11, an axial joint 12 and a second radial joint. Two radial joints 13, the butt joint 1 also includes several sealing layers, the pipe gallery also includes a water injection pipe 14, the end of the water injection pipe 14 communicates with the axial joint 12, and several sealing layers are in the butt joint 1 is arranged symmetrically with respect to the access point of the water injection pipe 14, and water is injected into the axial joint 12 through the water injection pipe 14 during the test. Compared with the method of injecting water from the outside to the inside, this method of injecting water from the middle and extending to the two outer ends is equivalent to conducting two sets of waterproof tests at the same time, which not only greatly i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com