A simulation modeling method of wheel rim

A simulation modeling and wheel rim technology, which is applied in design optimization/simulation, special data processing applications, instruments, etc., can solve the problems that the effect of the wheel hub cannot be reflected, bolts are not considered, and the strength verification of difficult-to-spoke plates is not considered, and the analysis results can be achieved. Accurate and reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to further illustrate the features of the present invention, please refer to the following detailed description and accompanying drawings of the present invention. The accompanying drawings are for reference and description only, and are not intended to limit the protection scope of the present invention.

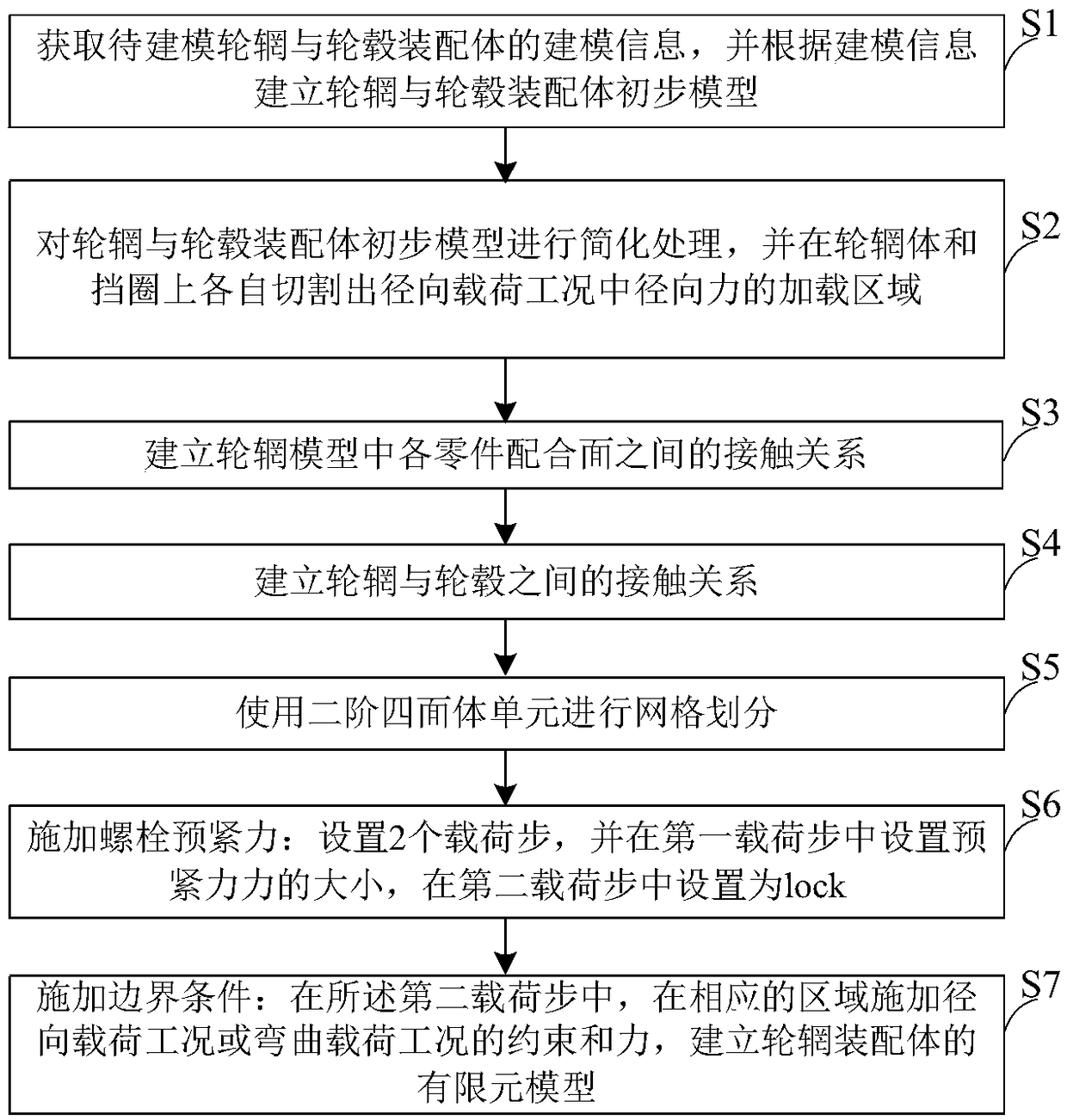

[0043] It should be noted that the simulation modeling software of the rim in this embodiment is ANSYS Workbench. The simulation modeling process of its rim is as follows: Figure 1 to Figure 5 As shown, including the following steps S1 to S7:

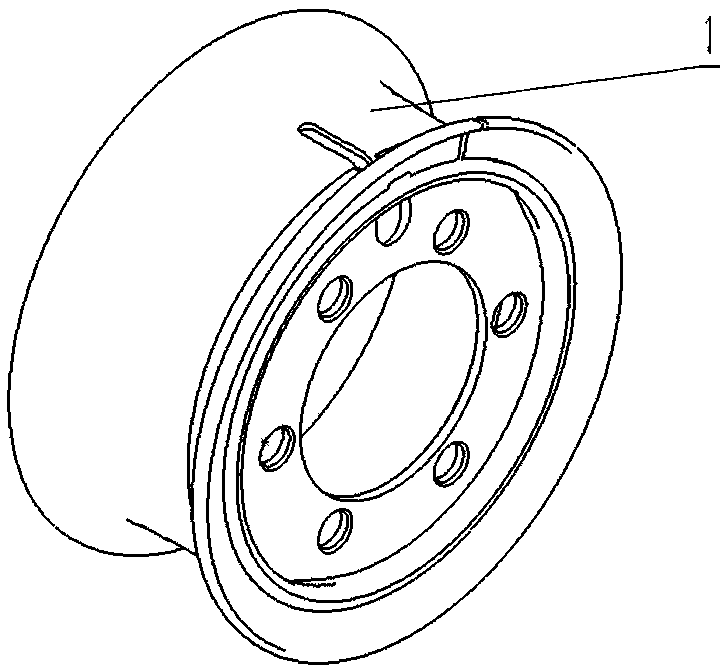

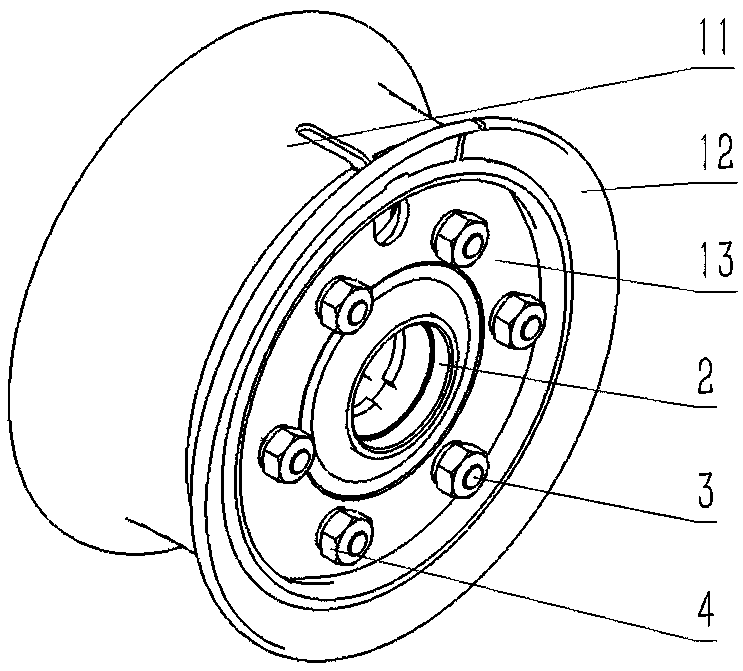

[0044] S1. Obtain the modeling information of the assembly of the rim 1 and the hub 2 to be modeled, and establish a preliminary model of the assembly of the rim 1 and the hub 2 according to the modeling information;

[0045] Among them, the modeling information of the assembly of rim 1 and hub 2 includes the three-dimensional model, load and parameter information of the assembly of rim 1 and hub 2, and a prelimina...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com