Ceiling cleaning device for construction

A technology for cleaning devices and ceilings, used in cleaning equipment, cleaning machinery, applications, etc., can solve the problems of excessive dust, low efficiency, asynchronous cleaning and water spraying, etc., and achieve the effect of improving the cleaning effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

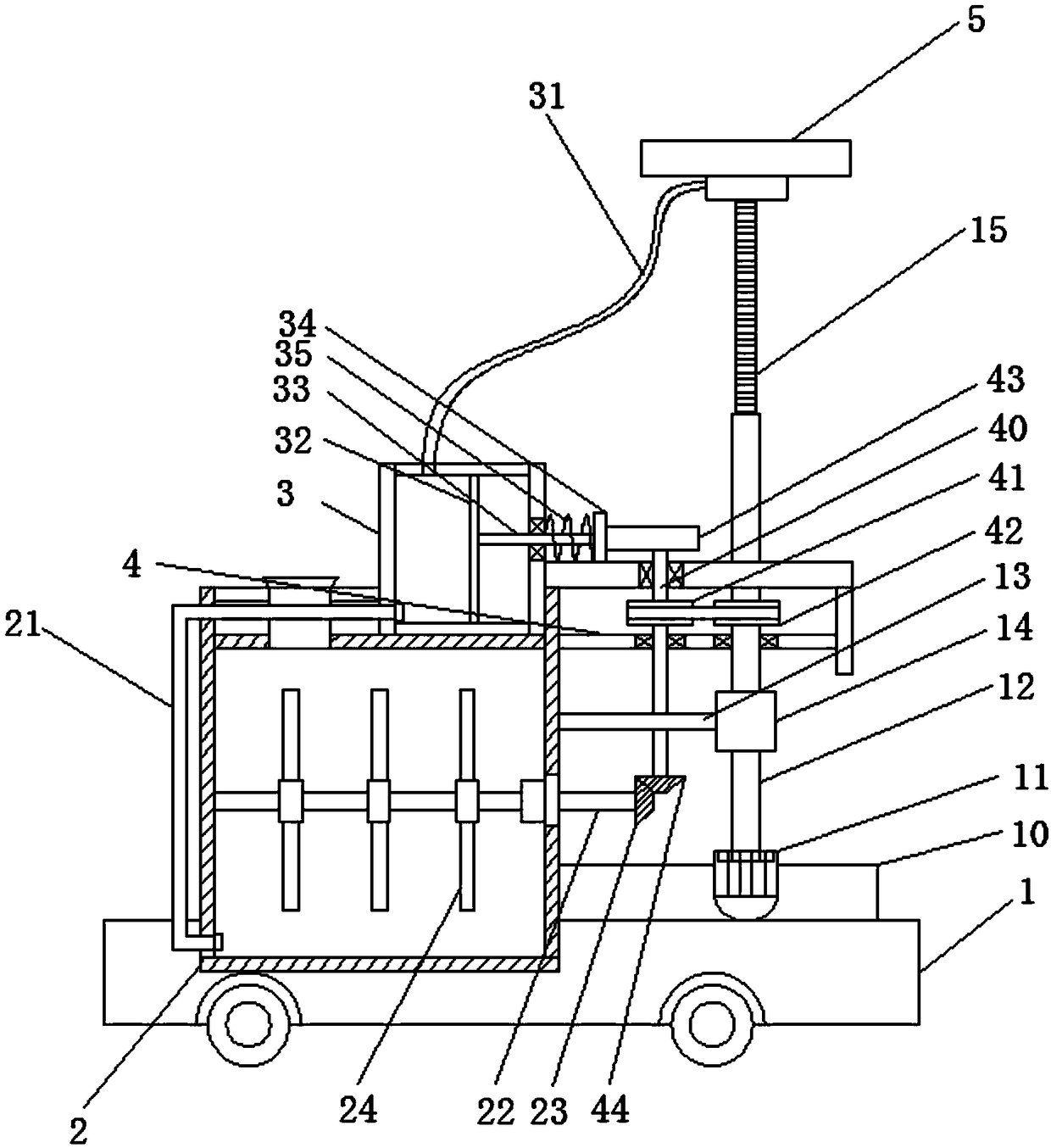

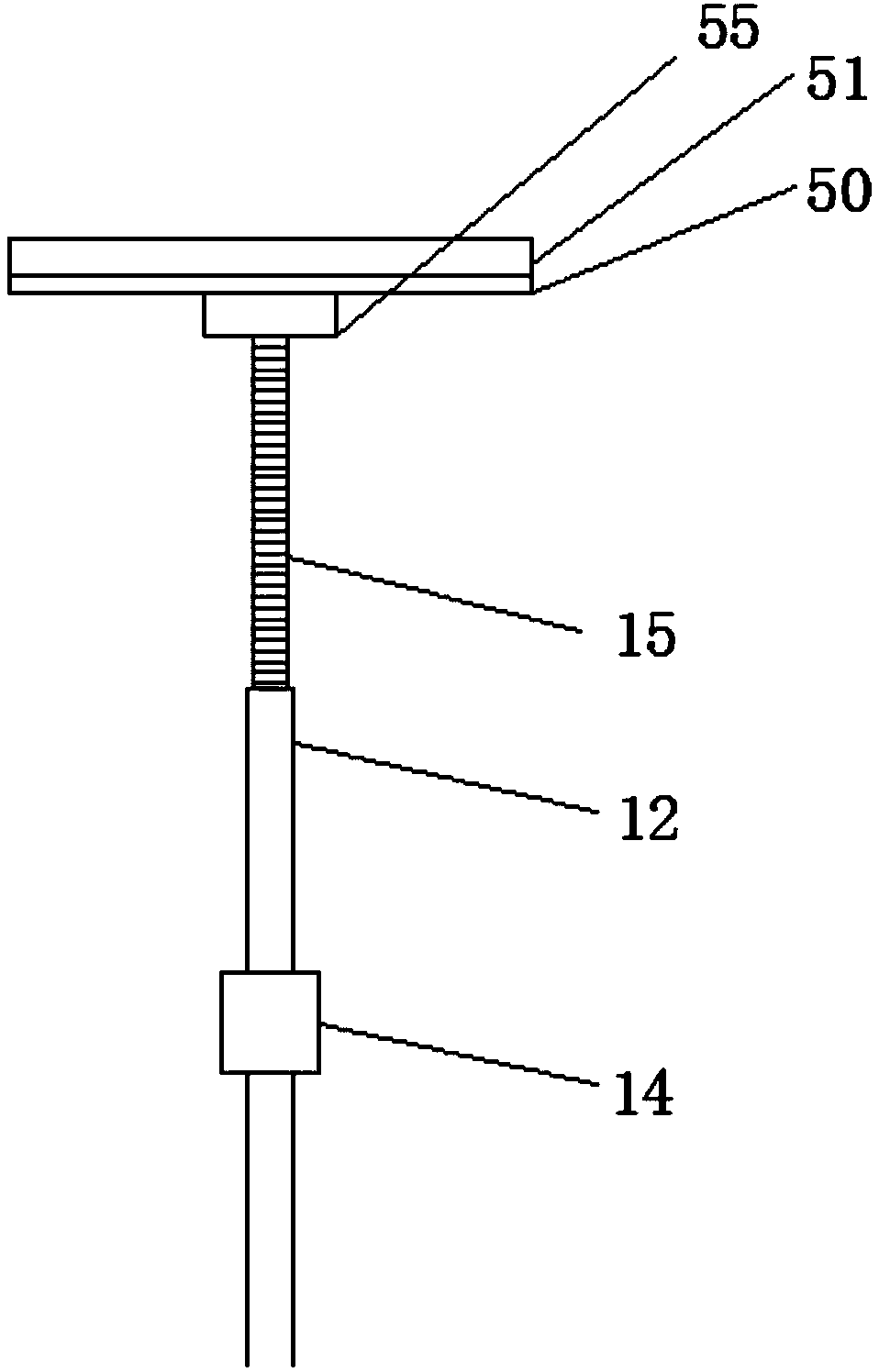

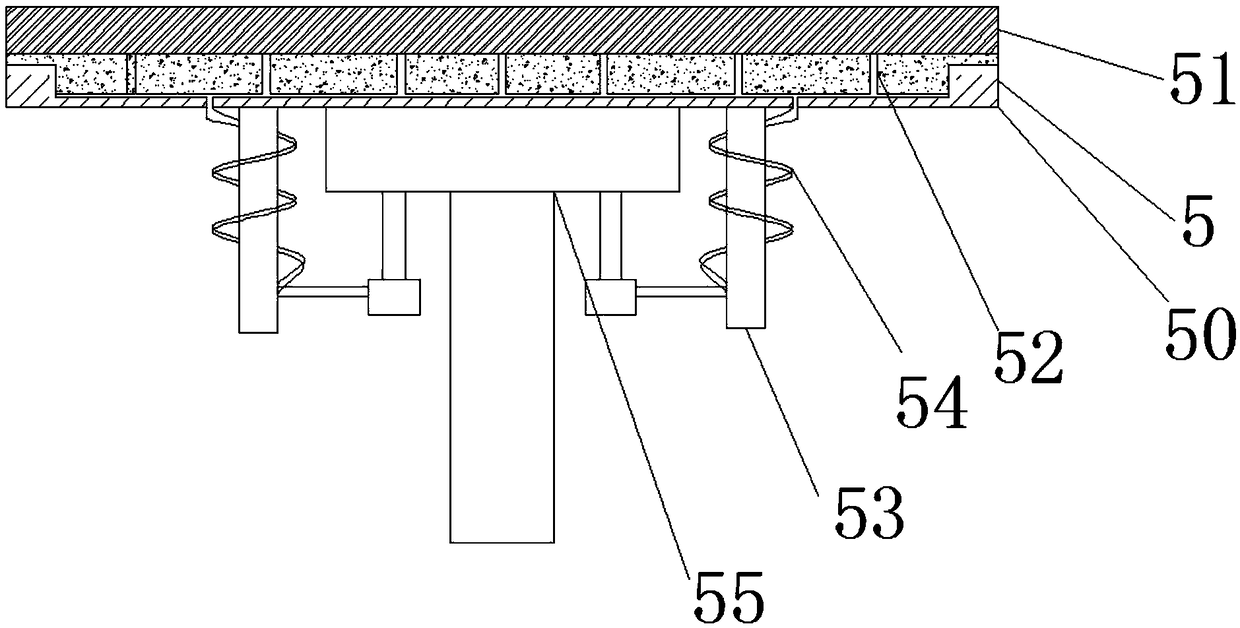

[0018] Example 1: Please refer to figure 2 with image 3 A fixing frame 13 is installed on the base 1, a fixing sleeve 14 is installed at the front end of the fixing frame 13, a transmission sleeve 12 is inserted into the fixing sleeve 14, and a base 10 is installed on the base 1, A drive motor 11 is installed on the base 10, the drive sleeve 12 is connected to the motor shaft of the drive motor 11 through a coupling, and a threaded rod 15 is penetrated in the drive sleeve 12, the threaded rod 15 external threads are provided on the outer wall, internal threads are provided on the inner wall of the transmission sleeve 12, the threaded rod 15 is engaged with the transmission sleeve 12 through threads, and a cleaning wipe 5 is installed on the top of the threaded rod 15, The cleaning wipe 5 is designed to have a disc-shaped structure. The cleaning wipe 5 includes a housing 20 and a wipe pad 51. The housing 20 is fixed on the bottom surface of the wipe pad 51. The bottom of the h...

Embodiment 2

[0021] Example 2: Please refer to figure 1 As a further solution of the first embodiment, the difference from the first embodiment is that a transmission shaft 40 is vertically installed on the frame 4, a transmission wheel 42 is installed on the transmission sleeve 12, and the transmission shaft 40 is A driven wheel 41 is installed, the driven wheel 41 and the transmission wheel 42 are connected by a belt, a cam 43 is installed at the top of the transmission shaft 40, a piston plate 32 is installed in the water delivery cylinder 3, and the piston plate 32 is connected with a piston rod 33. The front end of the piston rod 33 passes through the water delivery cylinder 3 and is equipped with a pressing plate 34 which is in contact with the cam 43. The front section of the piston rod 33 is wound with a reset A spring 35, one end of the return spring 35 is mounted on the pressing plate 34, and the other end of the return spring 35 is fixed on the front plane of the water delivery cy...

Embodiment 3

[0023] Example 3: Please refer to figure 1 As a further solution of the second embodiment, the difference from the second embodiment is that a stirring shaft 24 is installed horizontally in the water tank 2, and the stirring shaft 24 is installed horizontally to ensure the stirring range of the material at the bottom; the front end of the stirring shaft 24 A driven helical gear 23 is installed, a transmission helical gear 44 is installed at the bottom end of the transmission shaft 40, the transmission helical gear 44 meshes with the driven helical gear 23, and several pairs of stirring rods are installed on the stirring shaft 24 24. The stirring rod 24 is equidistantly installed on the stirring shaft 24, and the top of the water tank 2 is provided with a feeding port.

[0024] During operation, while the transmission shaft 40 rotates, the transmission helical gear 44 rotates synchronously, and the gear meshing transmission drives the stirring shaft 24 to rotate, thereby performing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com