Stirring, mixing and drying device for chemical fertilizers

A stirring mixing and drying device technology, which is applied in the direction of manure drying, mixer with rotating stirring device, drying gas arrangement, etc., can solve the problems of unfavorable mixing, high labor intensity, physical discomfort, etc., to speed up mixing efficiency and reduce labor Strength, Ease of Use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

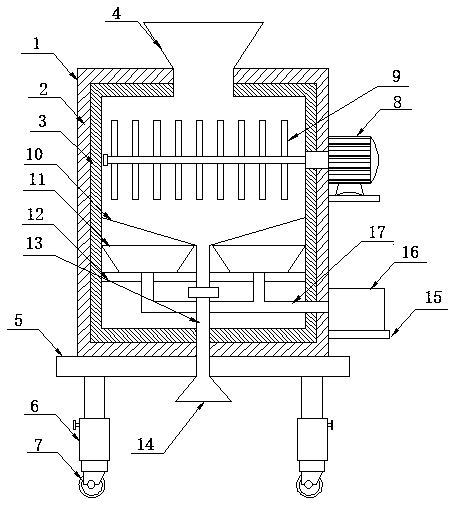

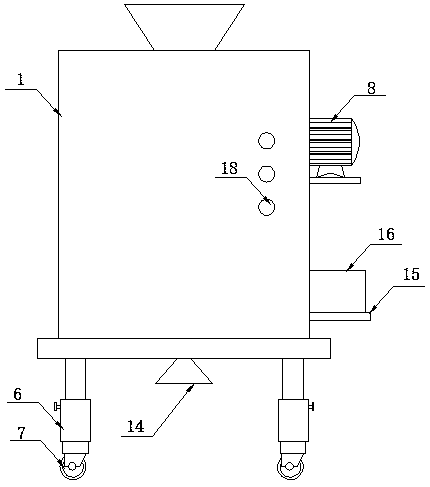

[0016] Such as Figure 1-2 As shown, the present invention discloses a chemical fertilizer mixing and drying device, comprising: a box body 1, a feed port 4, and a base 5, the inside of the box body 1 is provided with a waterproof layer 2, and the inside of the waterproof layer 2 is provided with a moisture-proof Layer 3, the top of the box 1 is provided with a feed port 4, the bottom of the box 1 is provided with a base 5, and the bottom of both ends of the base 5 is provided with telescopic adjustment rods 6, and each telescopic adjustment rod 6 The bottom is all provided with universal roller 7.

[0017] One side of the box body 1 is fixedly connected with a plurality of support plates 15 arranged horizontally, one of the support plates 15 is provided with a motor base, and the motor base is provided with a stirring motor 8, and the stirring motor 8 is connected through the rotation of the motor shaft. There is a rotating shaft, and a plurality of stirring shafts 9 are arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com