Pipe cutting machine tool

A technology for cutting pipes and machine tools, applied in the field of mechanical devices, can solve problems such as large errors and large workload, and achieve the effects of convenient transportation, reduced workload, and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

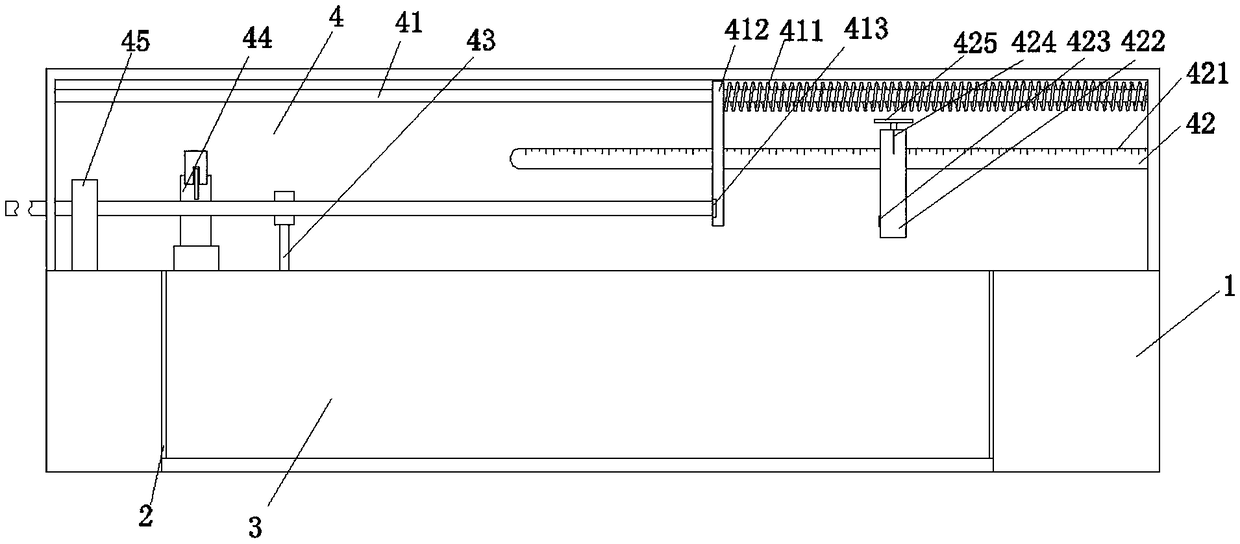

[0019] Such as Figure 1-4 As shown, a pipe cutting machine tool includes a machine base 1, the front of the machine base 1 is provided with a feeding trough 2 at the middle position near the bottom of the machine base 1, and the inner surface of the feeding chute 2 is provided with a storage box 3, and the front of the machine base 1 A working room 4 is arranged at the position above the material box 3 .

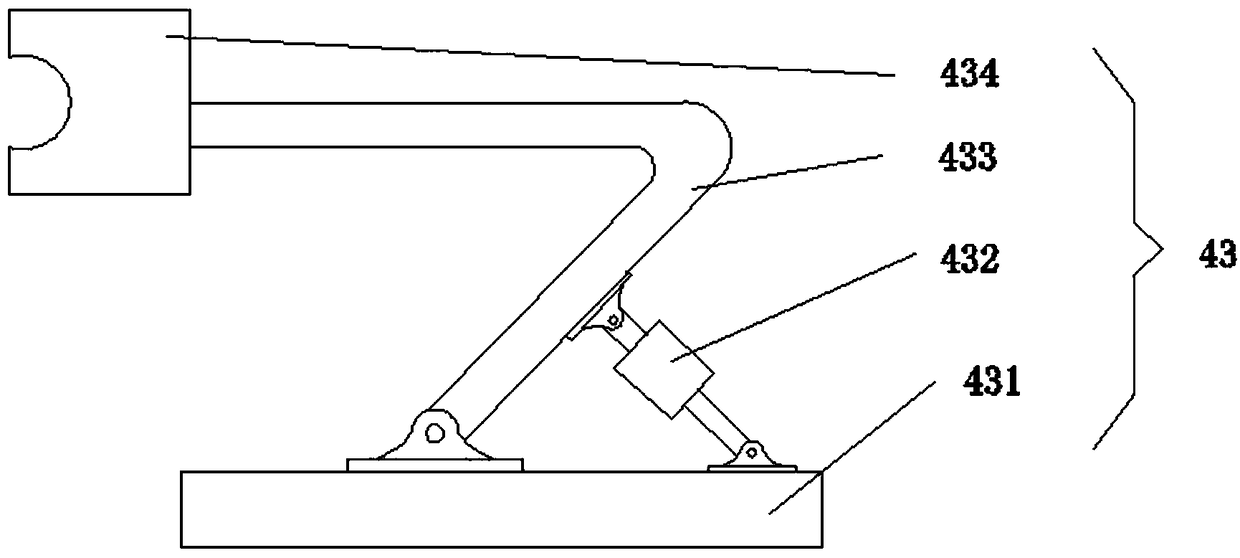

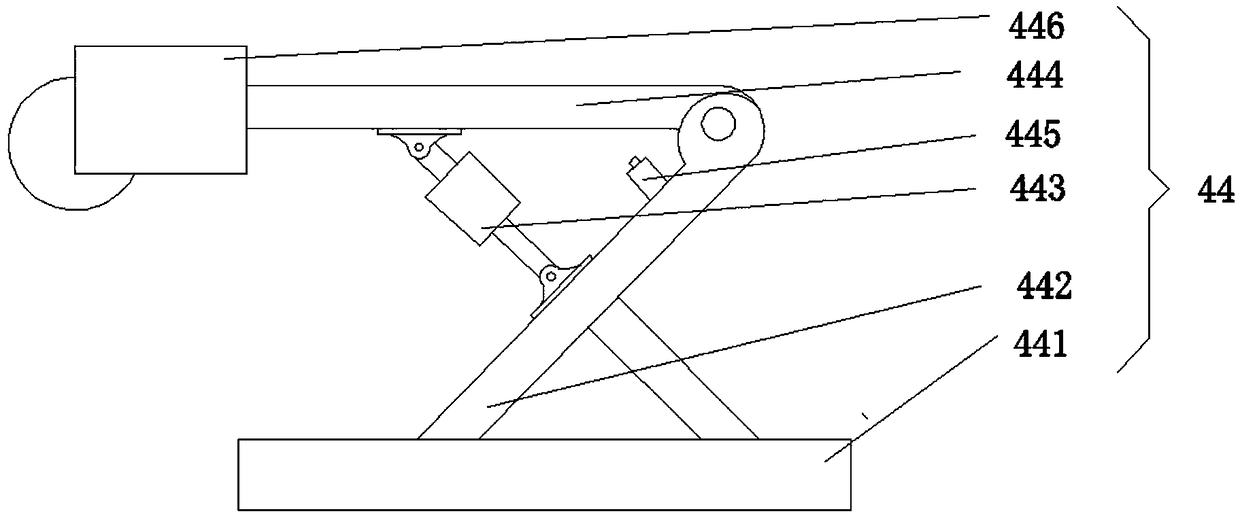

[0020] A pipe cutting machine tool of the present invention, by sliding the scale 421 on the benchmark rod 42, adjusting the proper position of the positioning seat 422 and the pipe cutting machine 446, then fixing the positioning seat 422, pushing the pipe so that one end of it is inserted into the upper pipe of the limit pipe seat 421 Fittin...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap