Battery rolling device

A rolling device and battery technology, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems that the product is not flat enough, the combination is not tight enough, and the battery pressure cannot be adjusted, so as to improve the measurement accuracy, roll uniformly, Install tight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

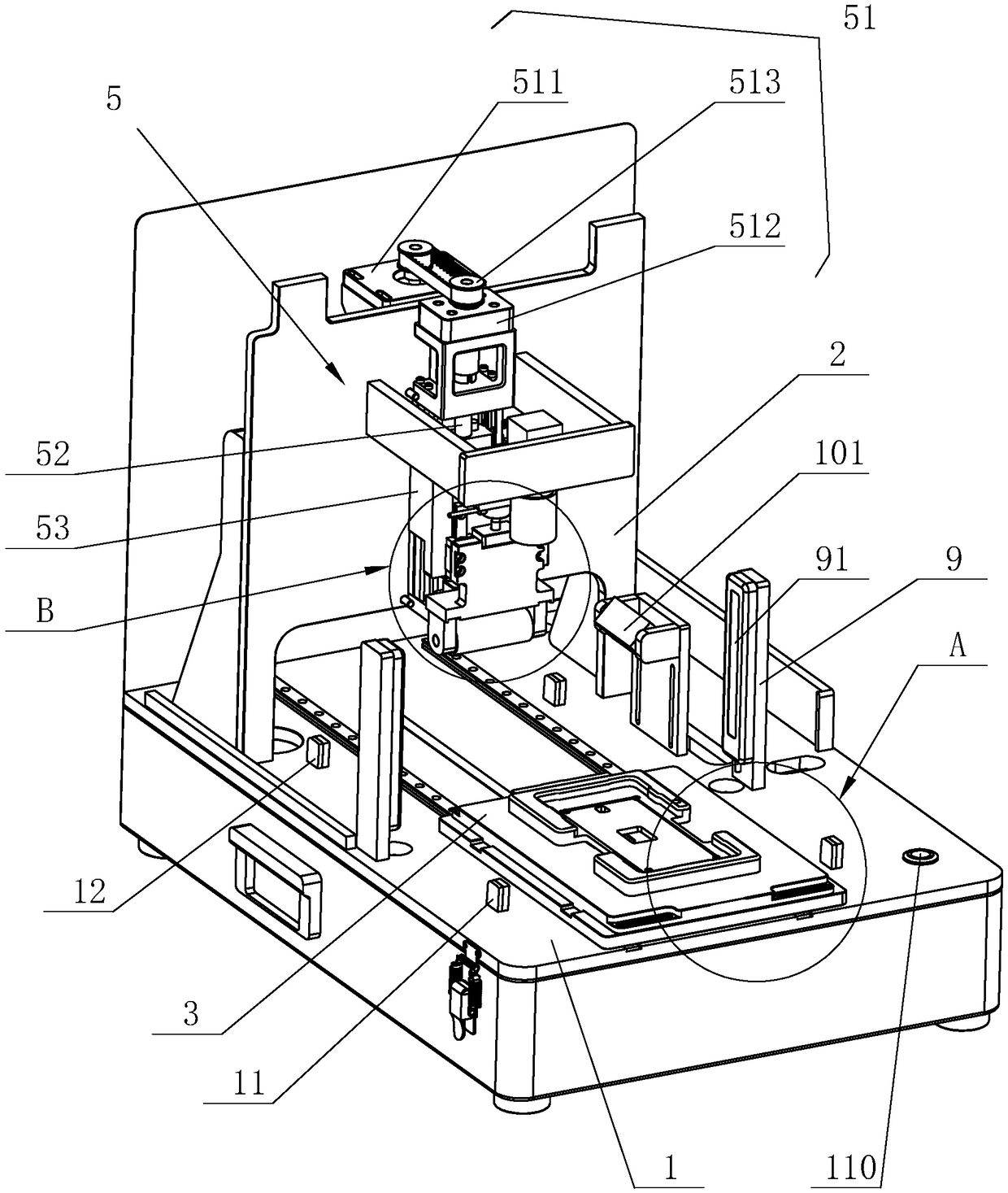

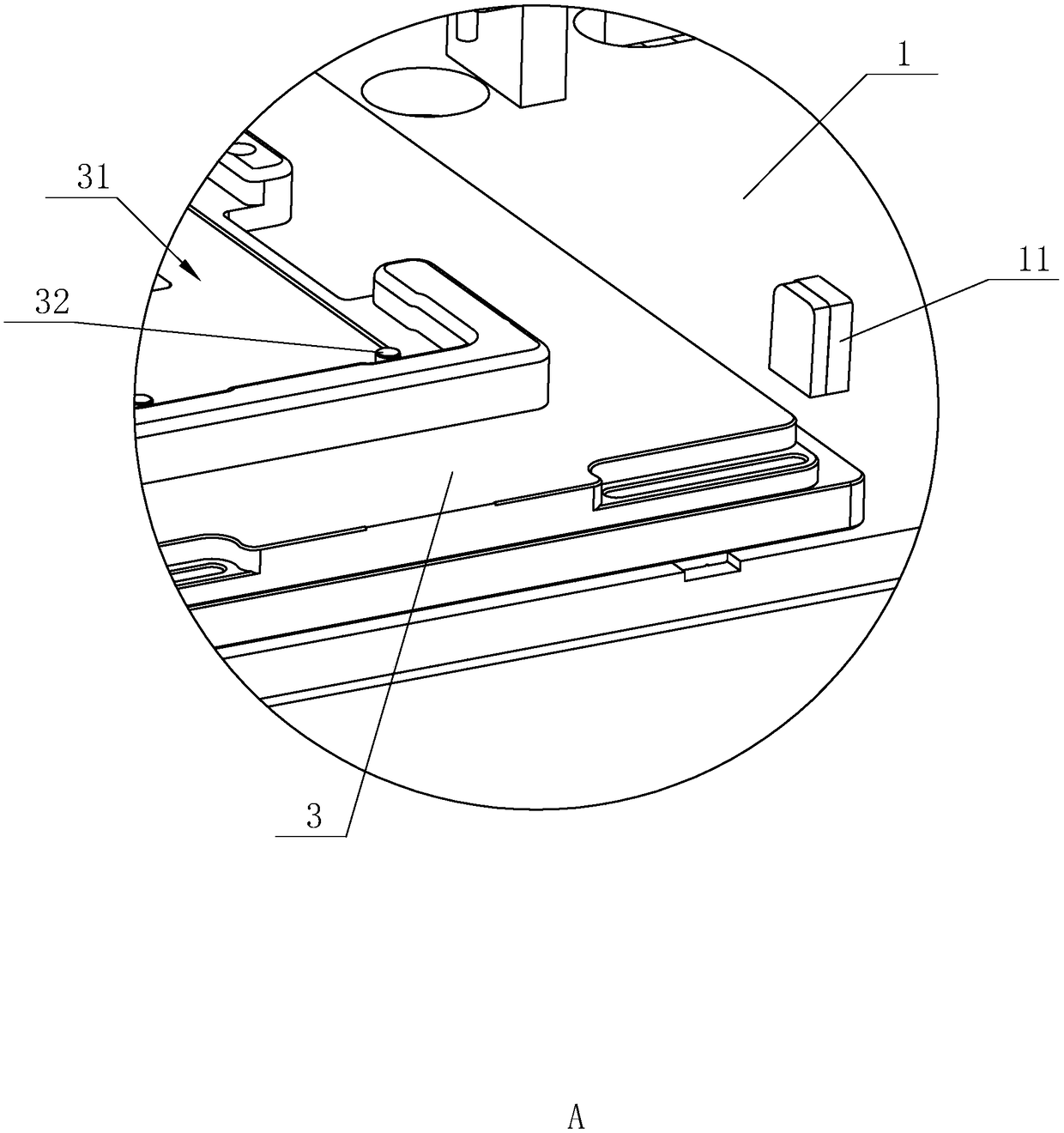

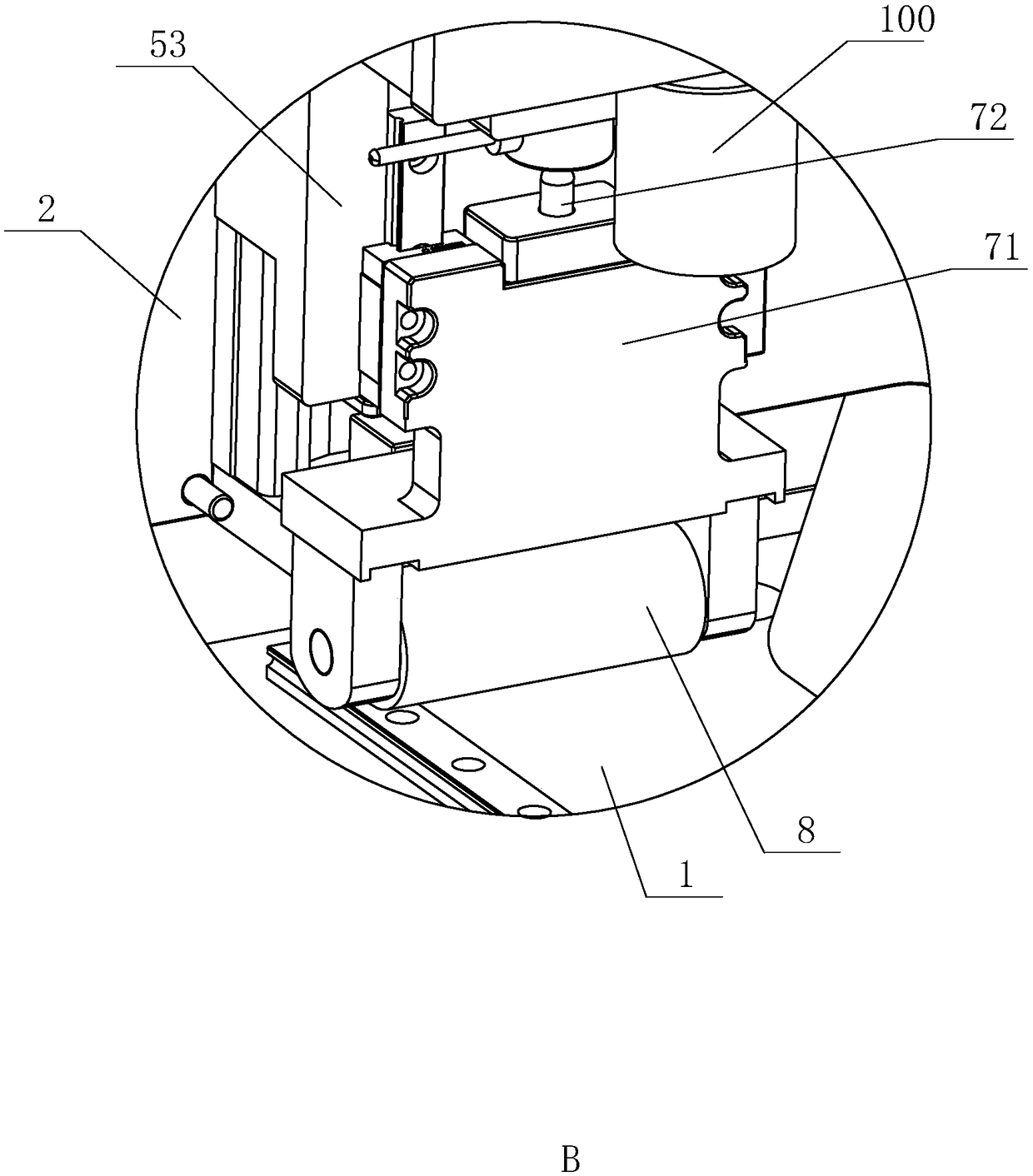

[0049] A battery rolling device such as figure 1 As shown, it includes a fixed base 1 placed horizontally, and a hollow frame-shaped installation frame 2 extending upward is fixedly connected to the fixed base 1 . The upper surface of the fixed base 1 is fixedly connected with a sliding track extending toward the middle of the mounting frame 2. The sliding track is in an inverted T shape, and the sliding track is slidably connected with a sliding seat 3 that slides back and forth toward the mounting frame 2. . The lower surface of the fixed base 1 is fixedly connected with a sliding driving member 4 which is arranged on the lower surface to drive the sliding seat 3 to slide.

[0050] Such as Figure 4 As shown, the sliding drive member 4 includes a sliding motor 41 welded and fixed on the lower surface of the fixed base 1, a sliding screw 42 with a coaxial center line is welded on the rotating shaft of the sliding motor 41, and the sliding screw 42 is connected to the The l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com