Grinding tool and method of fabricating the same

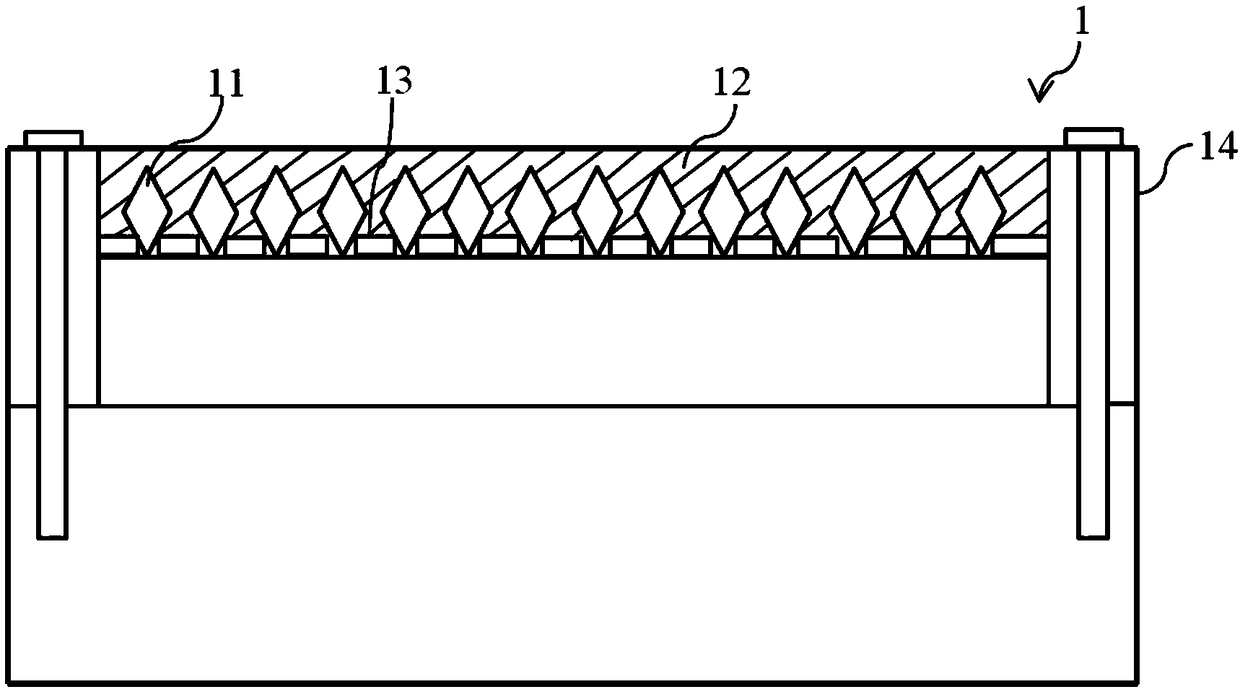

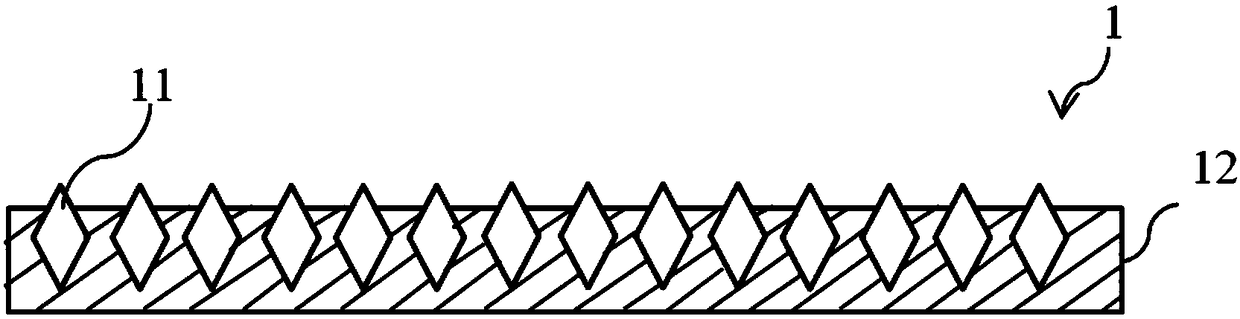

A technology for grinding tools and manufacturing methods, which is applied in the direction of grinding tools, manufacturing tools, abrasives, etc., and can solve the problems of falling of abrasive particles 11, damage of the surface of the grinding pad, and unstable fixing method, and achieves the characteristics of not easy to fall off, strong rigidity, and fixed The effect of high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

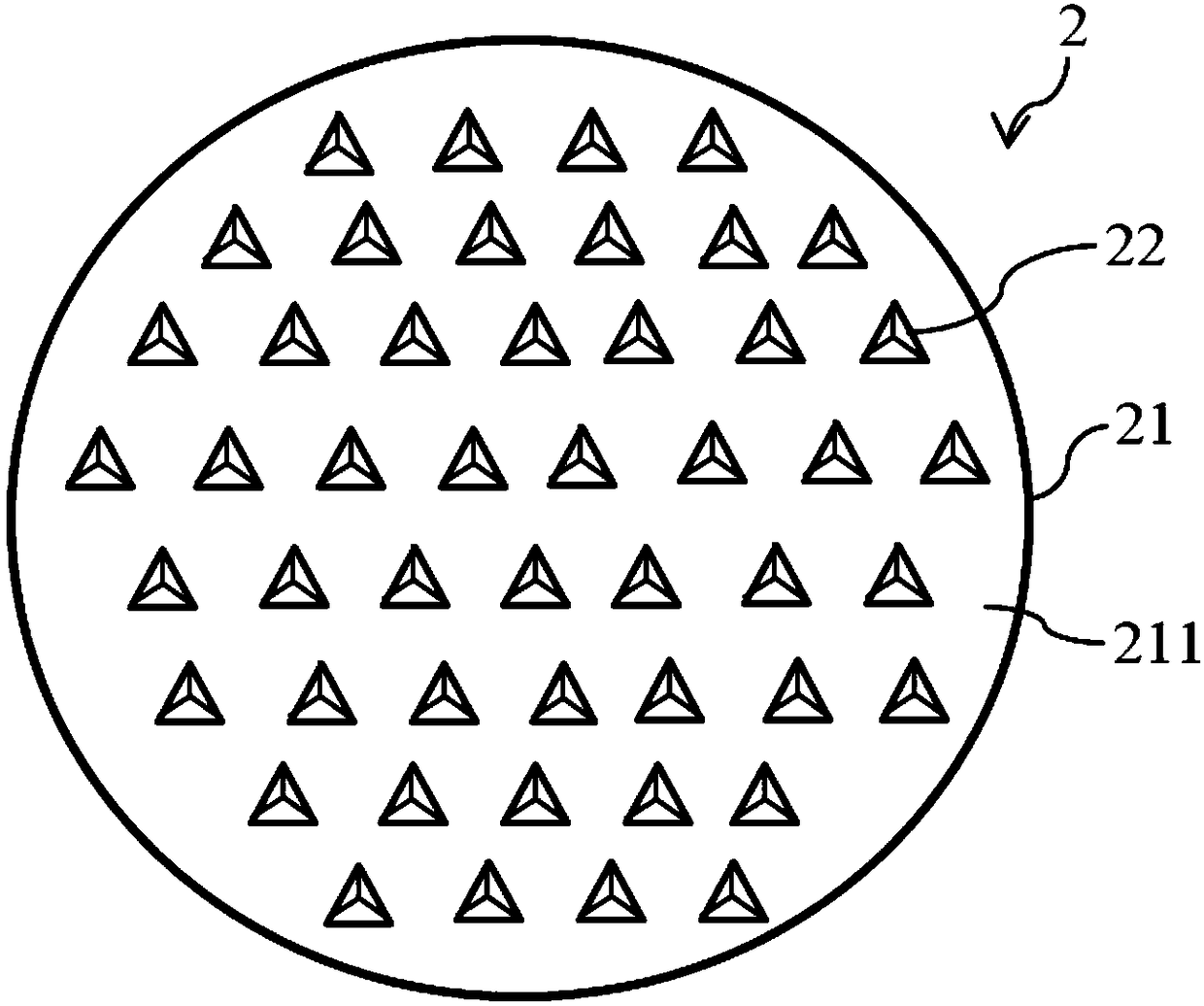

[0022] image 3 A top view of the grinding tool 2 provided by an embodiment of the present invention is shown, Figure 4 A cross-sectional view of the grinding tool 2 is then shown. refer to image 3 and Figure 4 , the abrasive tool 2 includes a substrate 21 and a plurality of abrasive particles 22 fixed on the substrate 21 . The substrate 21 is an integrally formed rigid single body. The material of the substrate 21 is a material with strong rigidity and stable chemical activity, such as a stainless steel substrate, a ceramic substrate, etc. Here, the stainless steel substrate is taken as an example, so that the substrate 21 can be slowed down in the process of using the grinding tool 2. Adverse effects of factors such as chemical activity. The size of the substrate 21 is not limited, it is 4 inches in this example, and its thickness can be 2-3 mm. The opposite sides of the substrate 21 have two surfaces 211, 212 respectively, wherein, the surface 211 is the working su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com