Preparation technology for BOPP tactile mercerized film

A preparation process and tactile technology, applied in the field of packaging materials, to achieve the effect of promoting adhesion, high fastness and improving surface tension coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

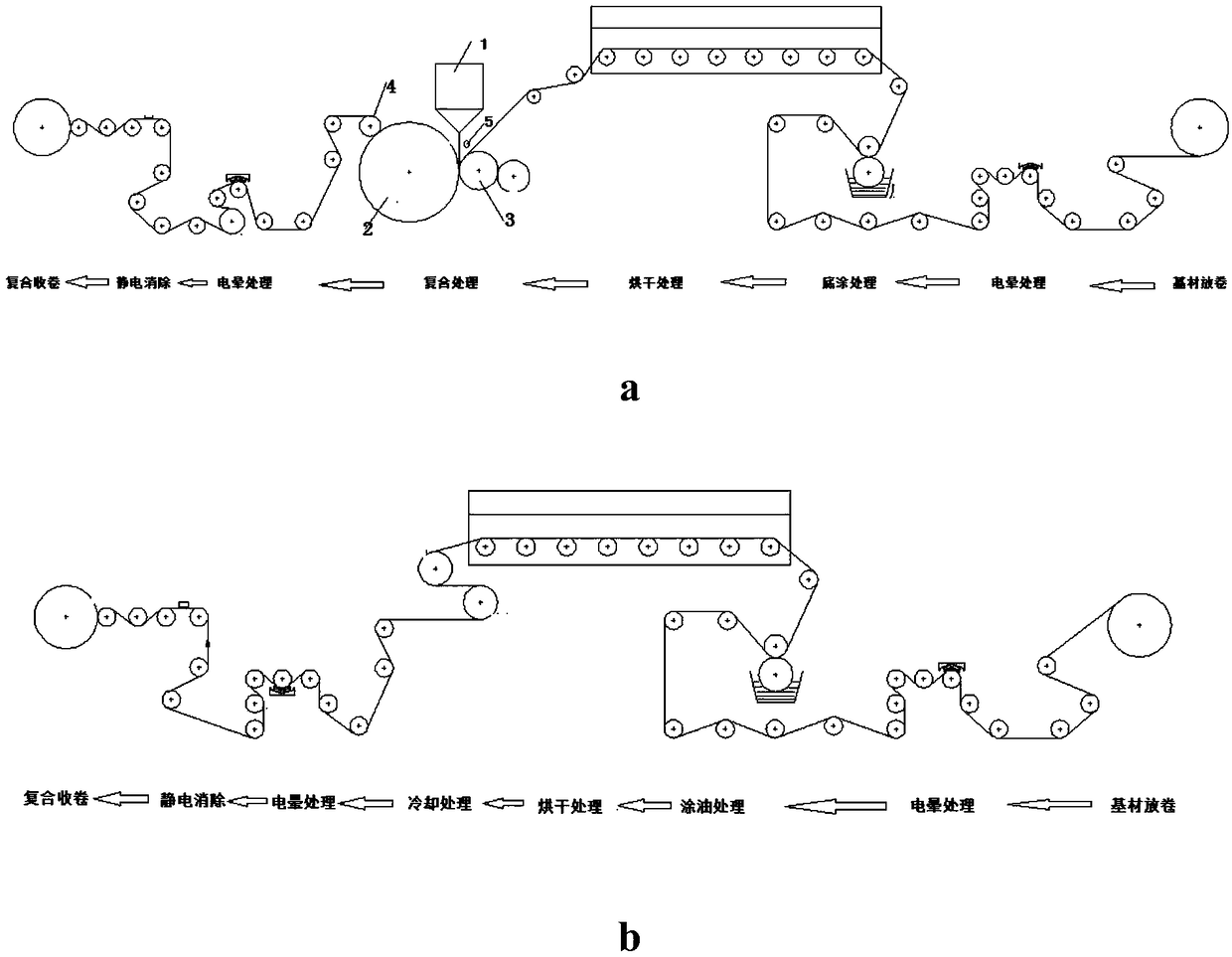

[0052] The first process:

[0053] (1) Substrate unwinding: Unwind the BOPP coil with unwinding equipment;

[0054] (2) Corona treatment: use corona treatment equipment to corona treat the inner side of the BOPP substrate, so that the inner surface tension coefficient reaches 42-46 dynes;

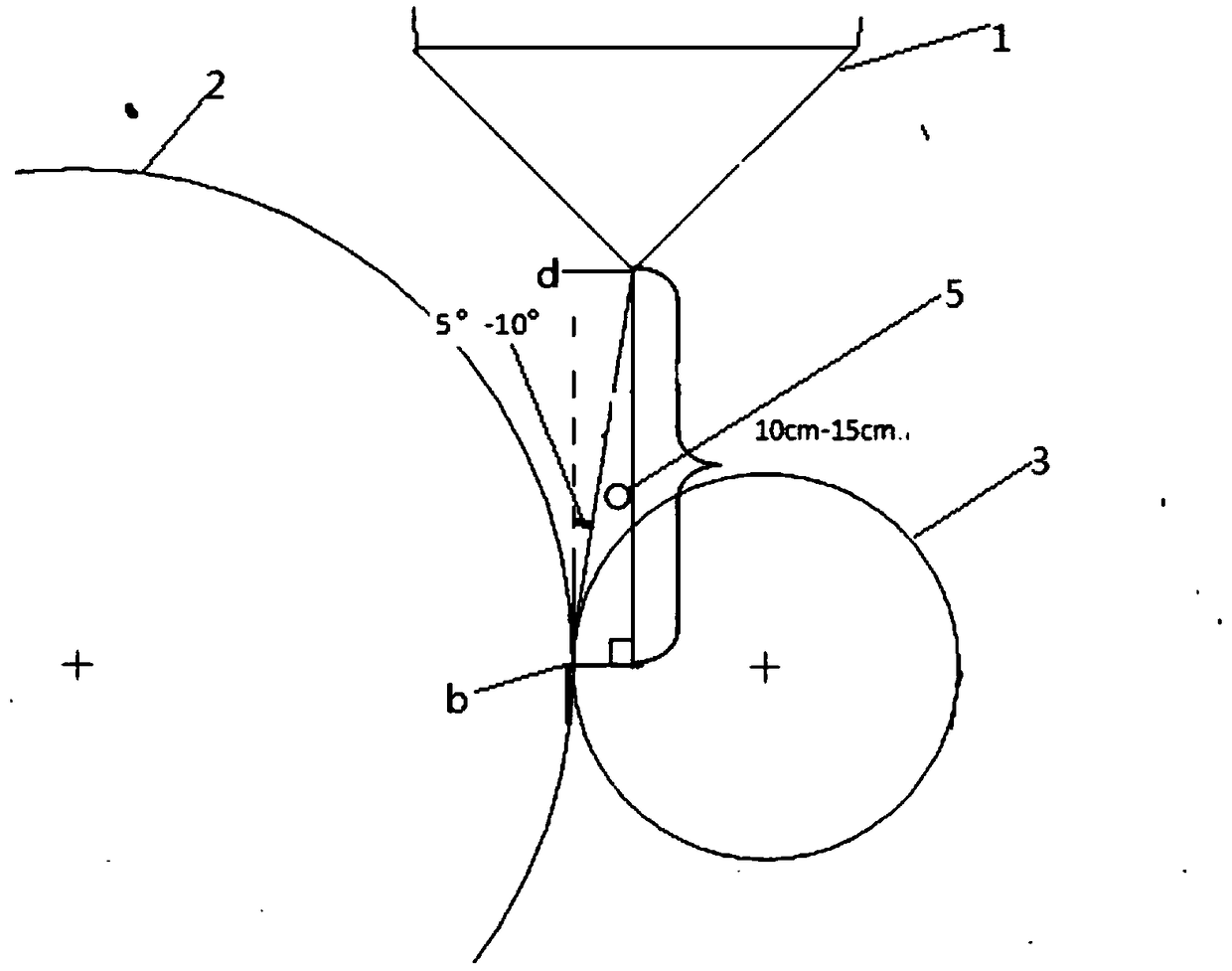

[0055] (3) Primer treatment: such as Figure 5 As shown, apply a layer of primer on the inner side of the corona treatment; the rubber roller is made of EPDM, and the ink-absorbing roller is made of mirror steel roller; the diameter of the rubber roller is 180mm: the diameter of the ink-absorbing roller is 230mm; the primer The agent is AC agent;

[0056] (4) Drying treatment: pass the BOPP base film coated with the primer through an oven, and dry under sealed conditions; the drying temperature is 55 ° C, and the drying time is 3 seconds;

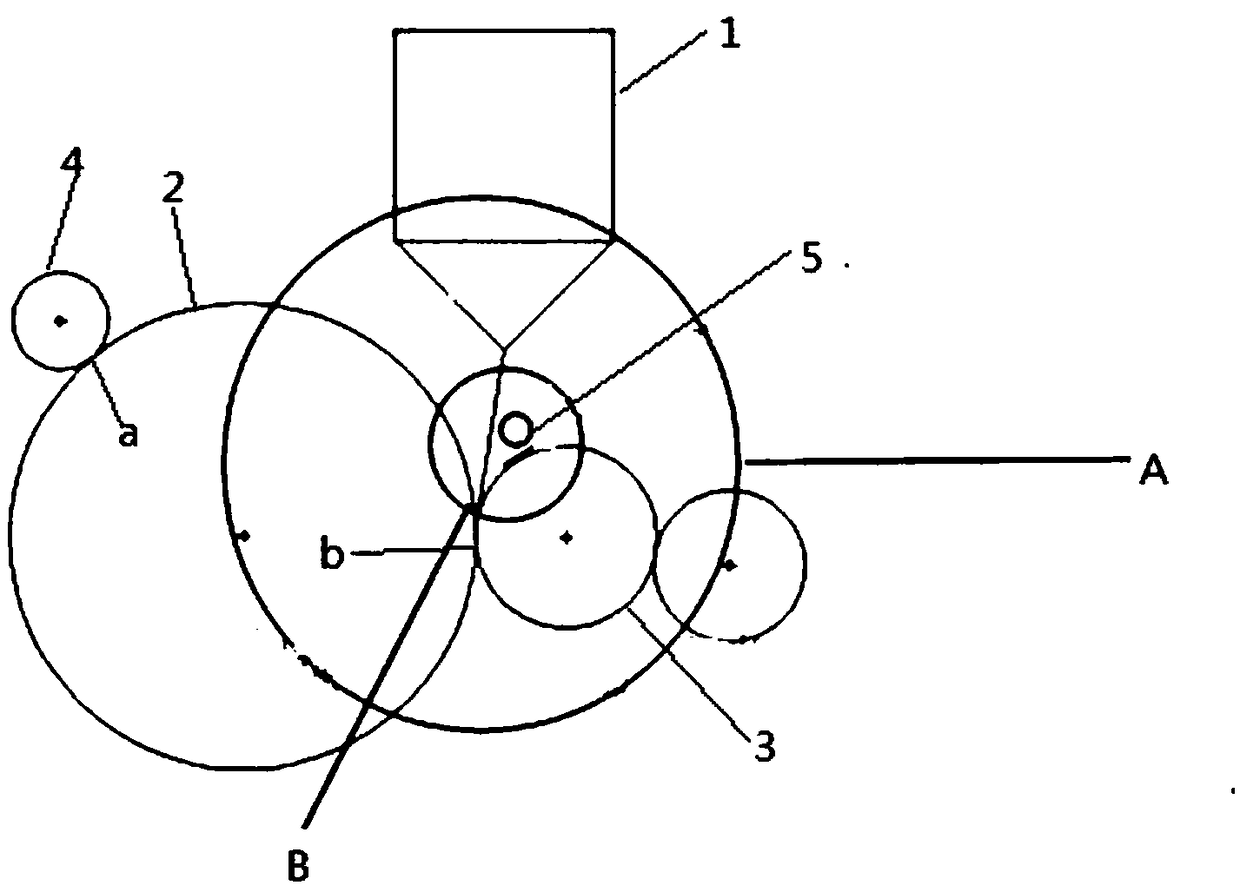

[0057] (5) Composite processing: such as Figure 2~4 As shown, first put the EVA resin particles in the extruder, heat the extruder and adjust the s...

Embodiment 2

[0081] The first process:

[0082] (1) Substrate unwinding: Unwind the BOPP coil with unwinding equipment;

[0083] (2) Corona treatment: use corona treatment equipment to corona treat the inner side of the BOPP substrate, so that the inner surface tension coefficient reaches 42-46 dynes;

[0084] (3) Primer treatment: apply a layer of primer on the inner side after corona treatment; the rubber roller is made of EPDM, and the ink-absorbing roller is made of mirror steel roller; the diameter of the rubber roller is 180mm: the diameter of the ink-absorbing roller is 230mm; Described primer is AC agent;

[0085] (4) Drying treatment: pass the BOPP base film coated with the primer through an oven, and dry under sealed conditions; the drying temperature is 58 ° C, and the drying time is 2.5 seconds;

[0086] (5) Composite processing: such as Figure 2~4 As shown, first put the EVA resin particles in the extruder, heat the extruder and adjust the speed of the extruder, the extrus...

Embodiment 3

[0110] The first process:

[0111] (1) Substrate unwinding: Unwind the BOPP coil with unwinding equipment;

[0112] (2) Corona treatment: use corona treatment equipment to corona treat the inner side of the BOPP substrate, so that the inner surface tension coefficient reaches 42-46 dynes;

[0113] (3) Primer treatment: apply a layer of primer on the inner side after corona treatment; the rubber roller is made of EPDM, and the ink-absorbing roller is made of mirror steel roller; the diameter of the rubber roller is 180mm: the diameter of the ink-absorbing roller is 230mm; Described primer is AC agent;

[0114] (4) Drying treatment: pass the BOPP base film coated with the primer through an oven, and dry under sealed conditions; the drying temperature is 58 ° C, and the drying time is 2.5 seconds;

[0115] (5) Composite processing: such as Figure 2~4 As shown, first put the EVA resin particles in the extruder, heat the extruder and adjust the speed of the extruder, the extrus...

PUM

| Property | Measurement | Unit |

|---|---|---|

| corona value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com