Waterproof coiled material spreading frame

A waterproof membrane and paving frame technology, applied in the field of paving frames, can solve problems such as low work efficiency, slanted roll material laying, and labor consumption, so as to achieve the effect of convenient laying and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

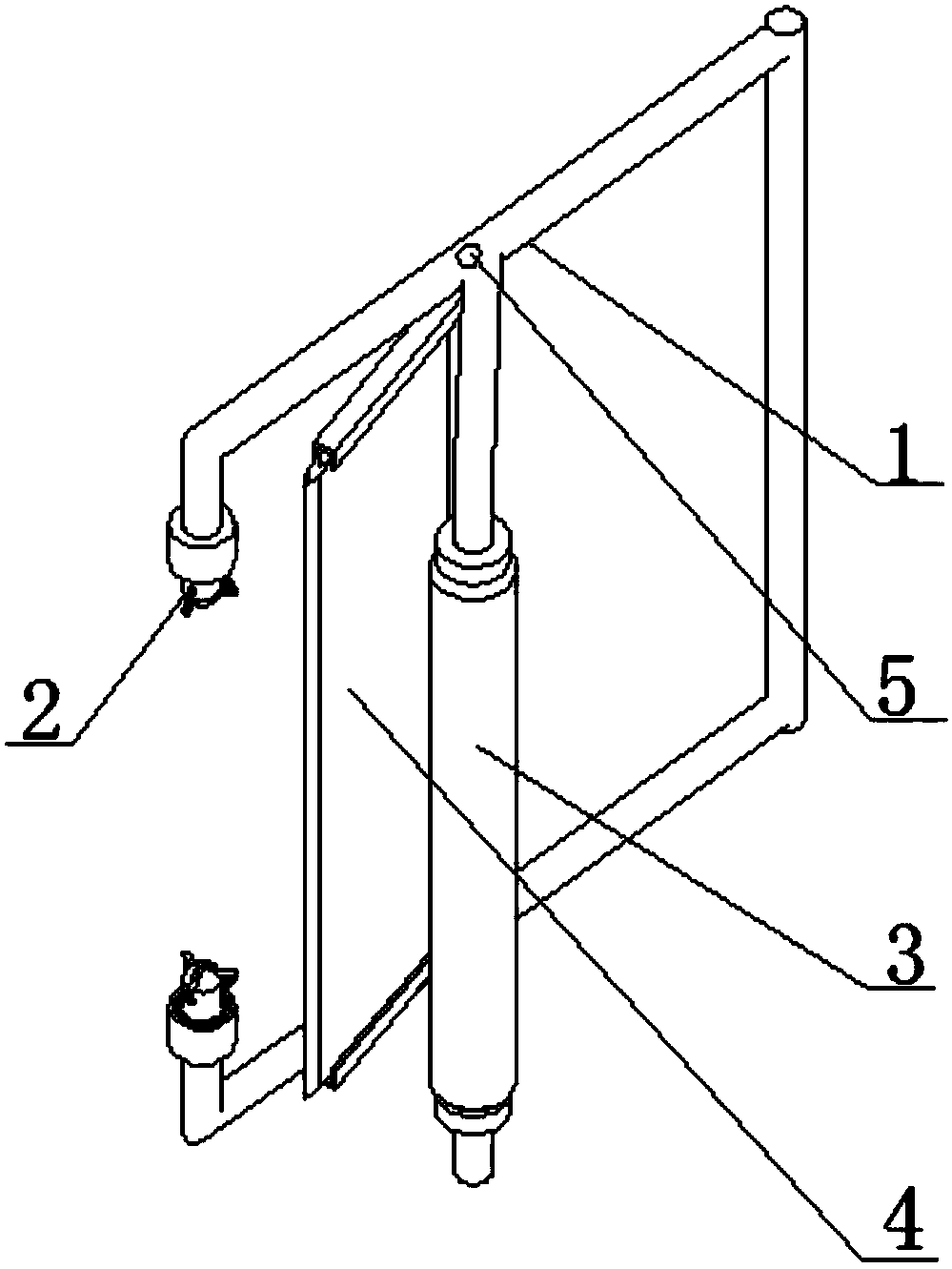

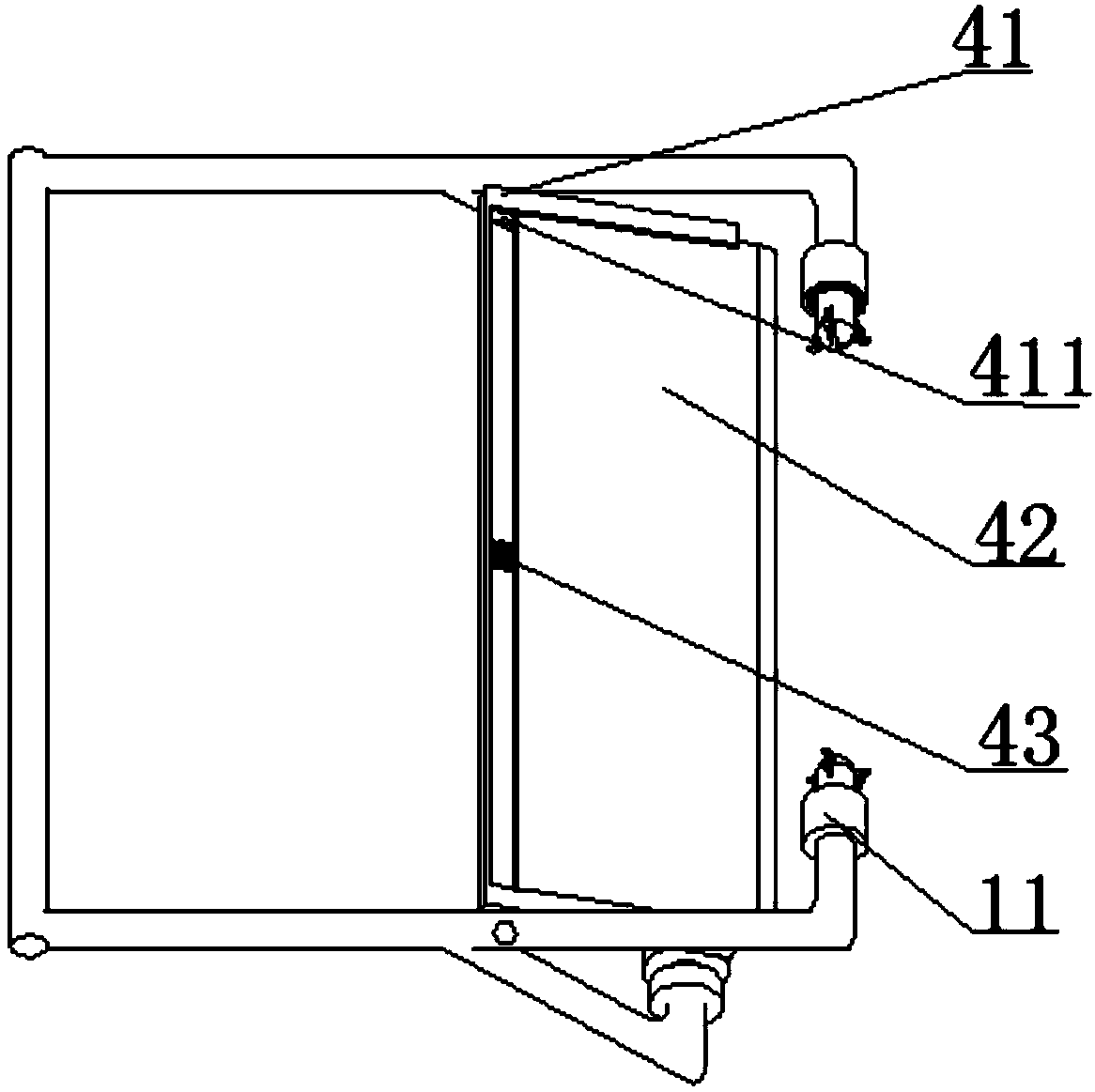

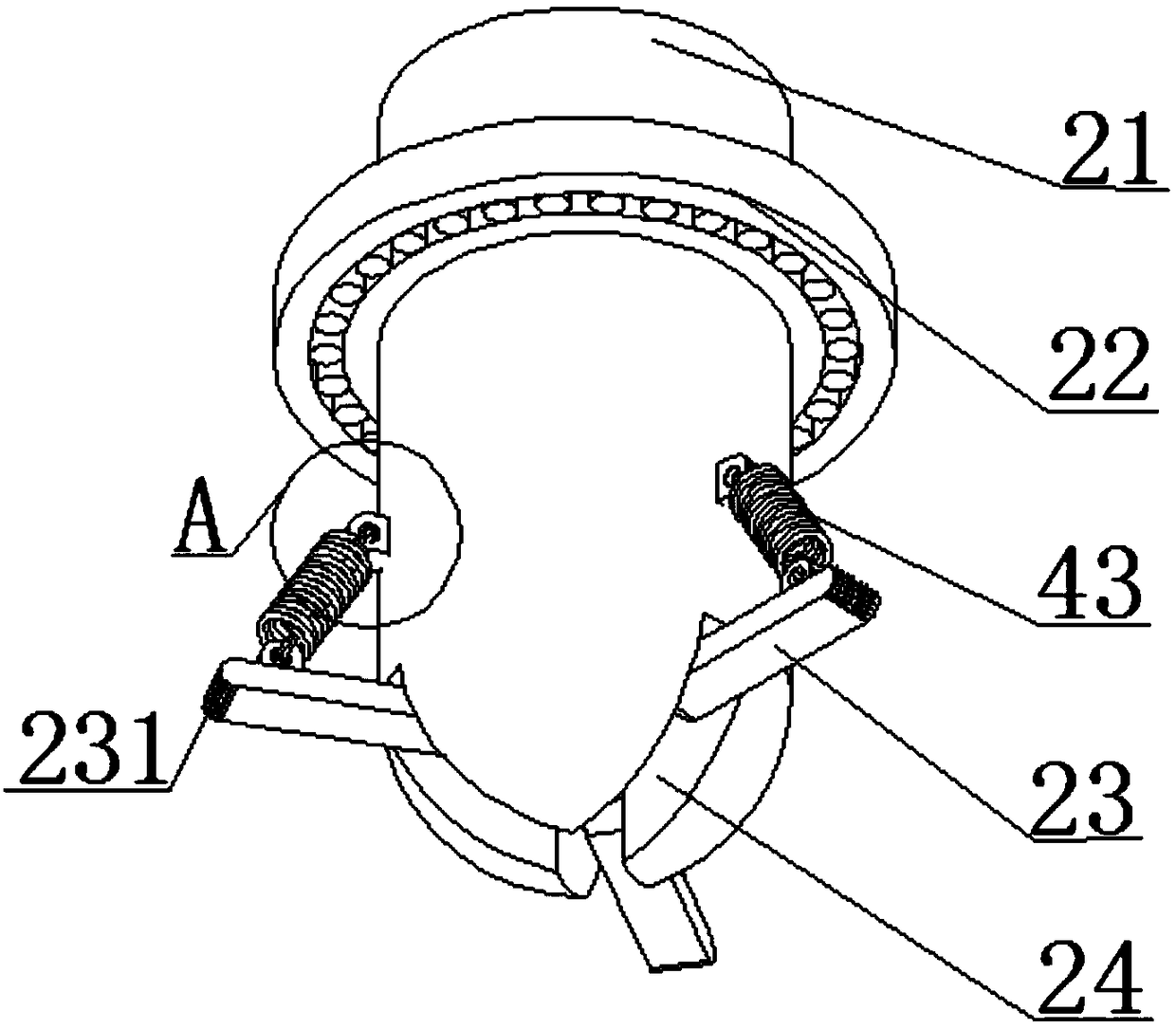

[0033] Example: refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 and Figure 7 As shown, a paving frame for waterproof coiled materials includes a frame 1, a clamp head 2, a roller 3 and a cutting knife 4. One end of the frame 1 is an open structure, and the other end is a handle 13. Branches are arranged in the middle of both sides. A pair of inwardly bent elbows 12 are provided at the port of the opening and each pair of elbows 12 is on a straight line, the two pairs of elbows 12 are parallel to each other, and the ends of the two elbows 12 at the opening are provided with Bearing box 11 is arranged, and chuck 2 is installed in bearing box 11, and the ends of two elbows 12 at branch are also all provided with bearing box 11, and roller 3 is installed between two bearing boxes 11, and branch and roller The shaft 3 can be used as an outrigger, and the waterproof membrane can also be rolled by the roller 3 to avoid wrinkles when laying the wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com