Aeration tank capable of adjusting aeration height conveniently

An aeration tank and aeration technology, which is applied in the field of aeration tanks, can solve the problems of a single aeration structure of the aeration tank and the inability to adjust the height of the aeration plate, and achieve the effect of improving the aeration efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

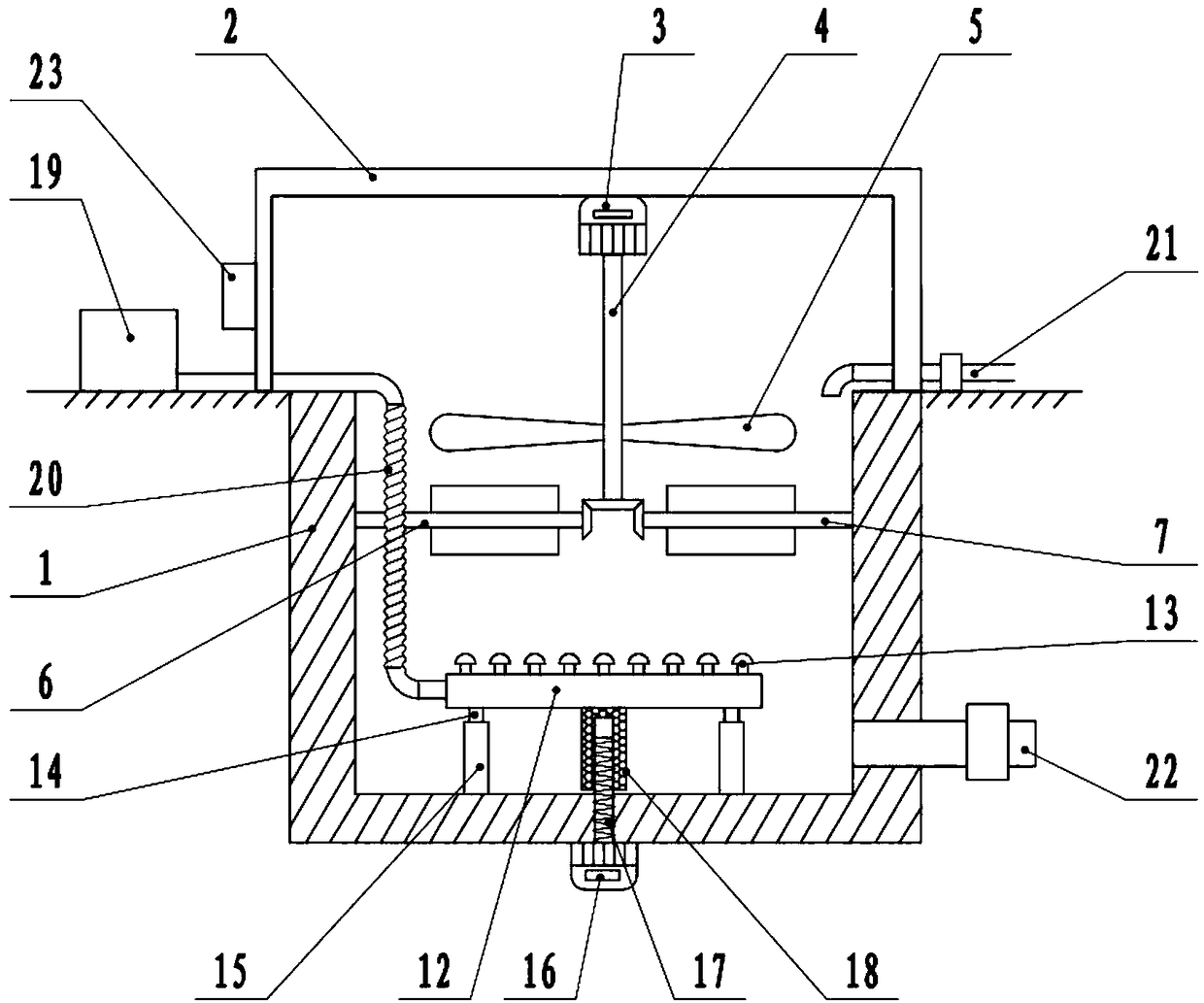

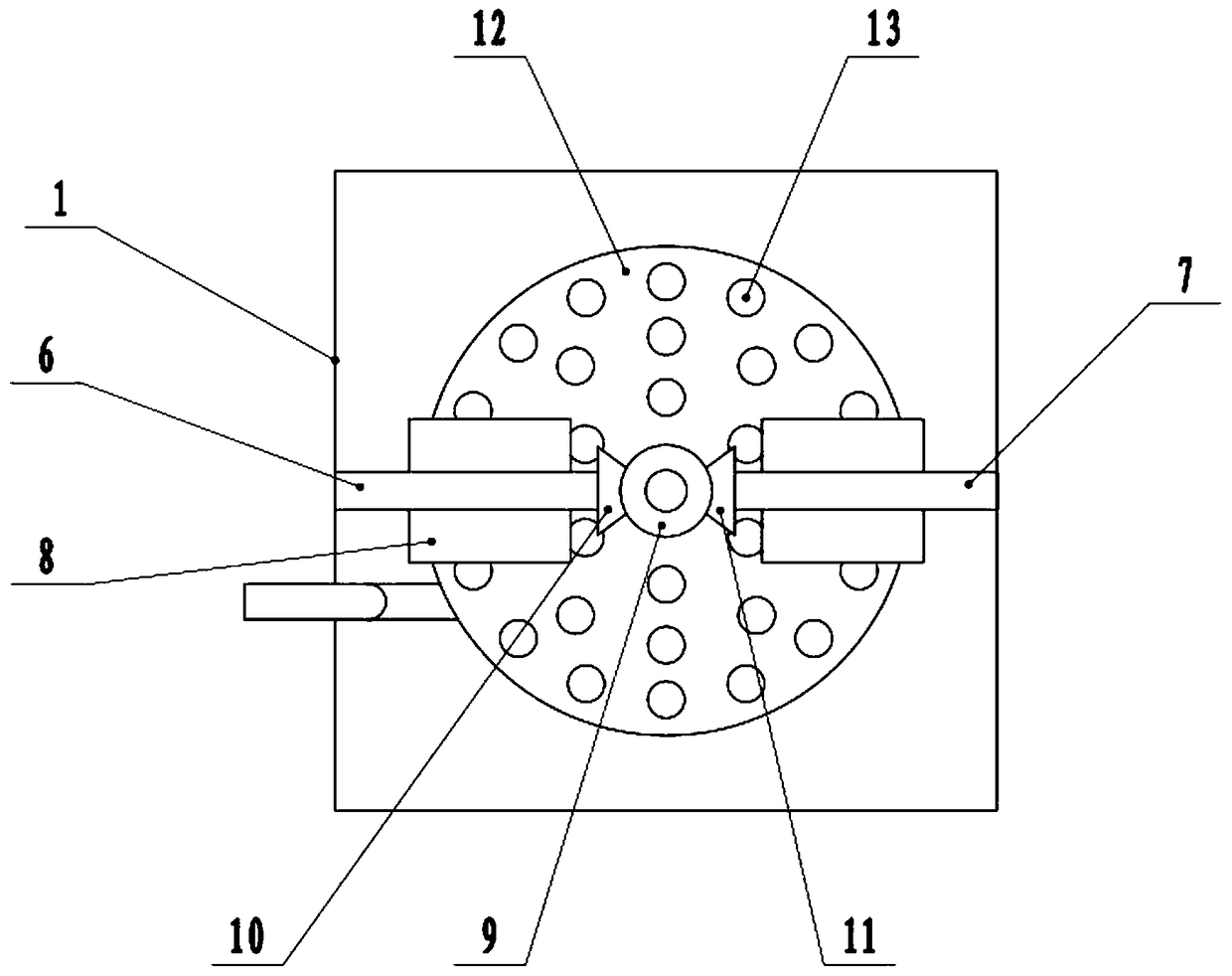

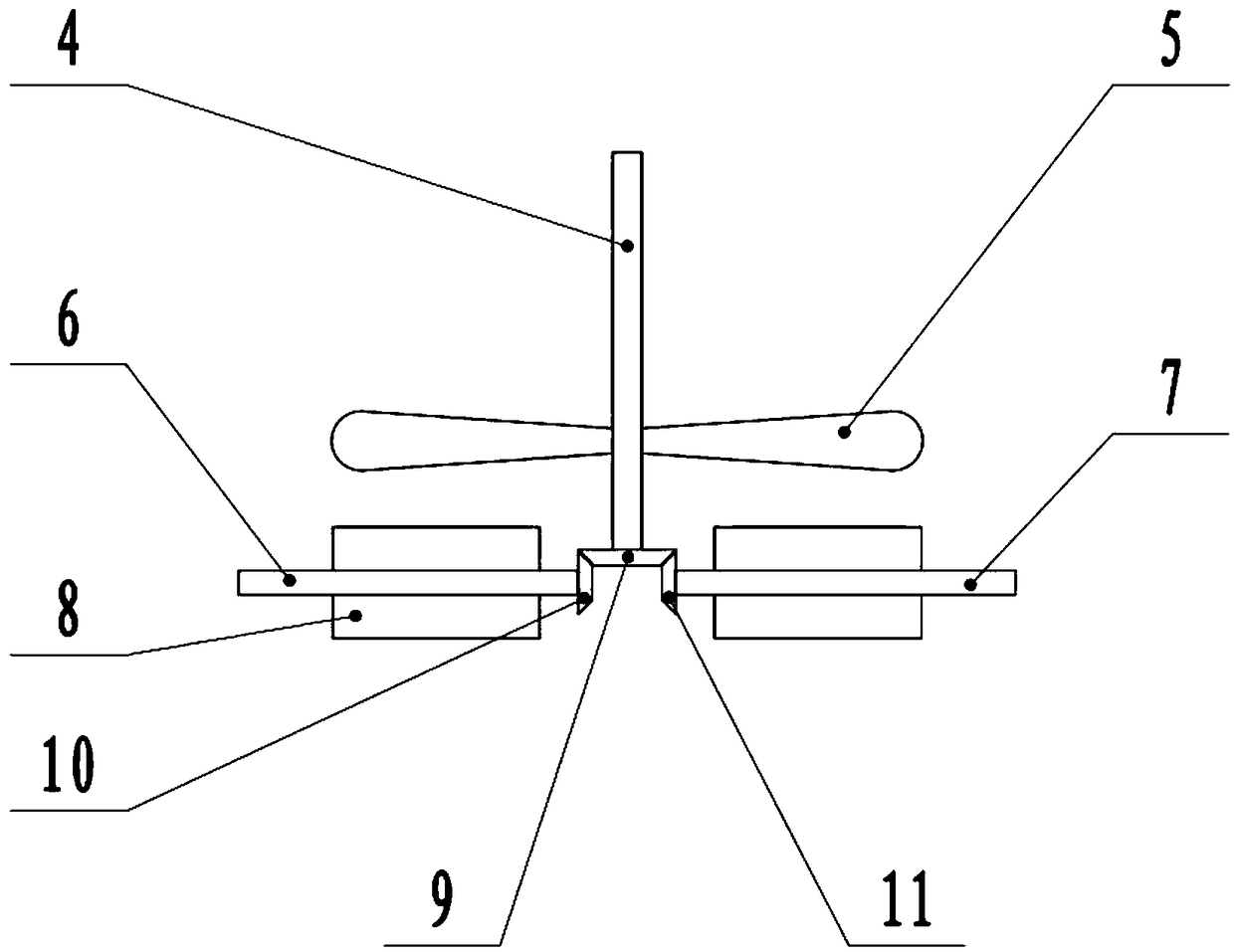

[0022] see Figure 1-3 , in an embodiment of the present invention, an aeration tank that is convenient for adjusting the aeration height includes a tank body 1, a fixed frame 2, an aeration blade 5, a water inlet pipe 21, and a drain pipe 22. The top of the tank body 1 is fixedly connected with a fixed Frame 2, the lower surface of the fixed frame 2 is fixedly connected with the aeration motor 3, the shaft extension end of the aeration motor 3 is fixedly connected with the transmission shaft 4, the lower end of the transmission shaft 4 extends into the pool body 1, and the transmission shaft 4 is fixedly connected There are aeration blades 5. When the aeration motor 3 is running, it drives the transmission shaft 4 to rotate, thereby driving the aeration blades 5 to rotate. The aeration blades 5 are used to raise the surface sewage, so that the surface sewage can fully contact with the air, and aerate the surface sewage , the bottom of the pool body 1 is provided with an aerat...

Embodiment 2

[0025] On the basis of Embodiment 1, the left and right sides of the transmission shaft 4 are respectively provided with a left rotation shaft 6 and a right rotation shaft 7, and the left rotation shaft 6 and the right rotation shaft 7 are respectively connected in rotation with the left side wall and the right side wall of the pool body 1. The rotating shaft 6 and the right rotating shaft 7 are respectively fixedly connected with a stirring plate 8, the lower end of the transmission shaft 4 is provided with a driving bevel gear 9, the right end of the left rotating shaft 6 is provided with a left bevel gear 10, and the left end of the right rotating shaft 7 is provided with a right bevel gear. Bevel gear 11, left bevel gear 10, and right bevel gear 11 mesh with driving bevel gear 9 respectively. When the transmission shaft 4 rotates, it drives the left shaft 6 and right shaft 7 to rotate synchronously, thereby driving the stirring plate 8 to rotate, and using the stirring plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com