A kind of high-performance environment-friendly capacitor dielectric and preparation method thereof

A capacitor and high-performance technology, applied in the field of capacitors, can solve the problems of low efficiency and achieve the effects of high production efficiency, improved withstand voltage performance, and large energy storage density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The preparation method steps of the high-performance environment-friendly capacitor dielectric of the present embodiment are as follows:

[0037] Step 1: Preparation of Bi 0.83 SM 0.17 Fe 0.95 sc 0.05 o 3 (BSFSO) powder.

[0038] In this example, the total amount of the obtained BSFSO powder is 0.08mol, and the raw materials for the preparation of the BSFSO powder are shown in Table 1:

[0039] Table 1 Preparation raw materials of BSFSO powder

[0040] Drug Name molecular weight Drug purity Experimental ratio stoichiometric number Weighing quality bismuth trioxide 465.96 0.9999 1 0.83 15.4714g Samarium trioxide 348.7 0.9999 1 0.17 2.3714g Ferric oxide 159.69 0.999 1 0.95 6.0742g scandium trioxide 137.91 0.999 1 0.05 0.2760g

[0041] Specific steps are as follows:

[0042] 1) Take each raw material according to the weighing quality in Table 1;

[0043] 2) Put the weighed raw materials into the nylon ...

Embodiment 2

[0057] The preparation method of the high-performance environment-friendly capacitor dielectric of this embodiment is basically the same as that of Embodiment 1, the difference lies in the following two points:

[0058] ① Step 3 and step 4) During the hot pressing sintering process, through the cooperation of two experimenters, the sintering temperature was first raised to three different temperatures of 860°C, 840°C, and 820°C, and then kept for 5 minutes, and then obtained after cooling down. Three BSFSO ceramic samples prepared at different sintering temperatures.

[0059] ② Step 2 of Step 4) When plating the top electrode, the diameter of the hole on the mask used is 1mm.

Embodiment 3

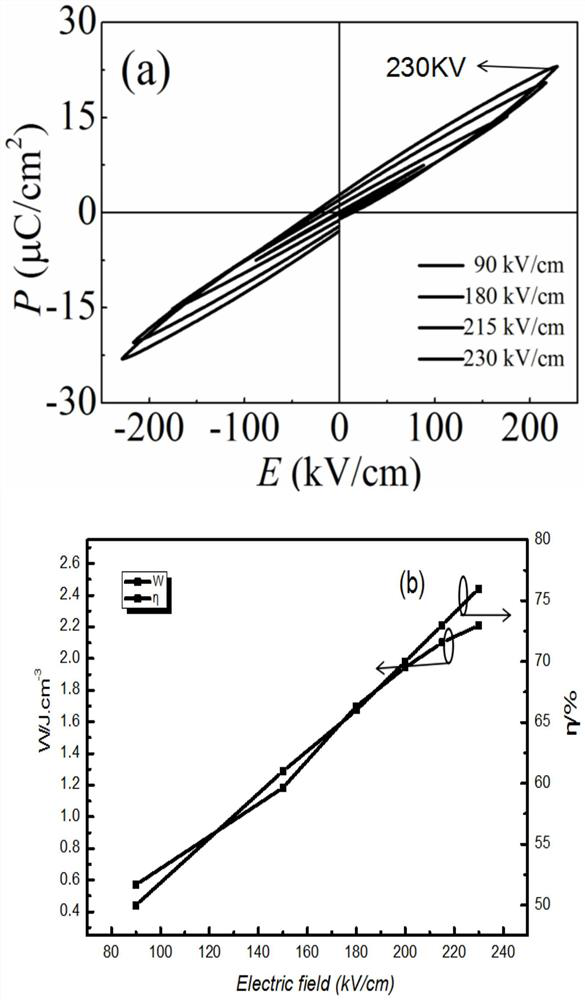

[0061] The high-performance environment-friendly capacitor dielectric that embodiment 1 and embodiment 2 make, i.e. the performance of BSFSO ceramics (samarium scandium co-doped BFO ceramics) is tested and characterized:

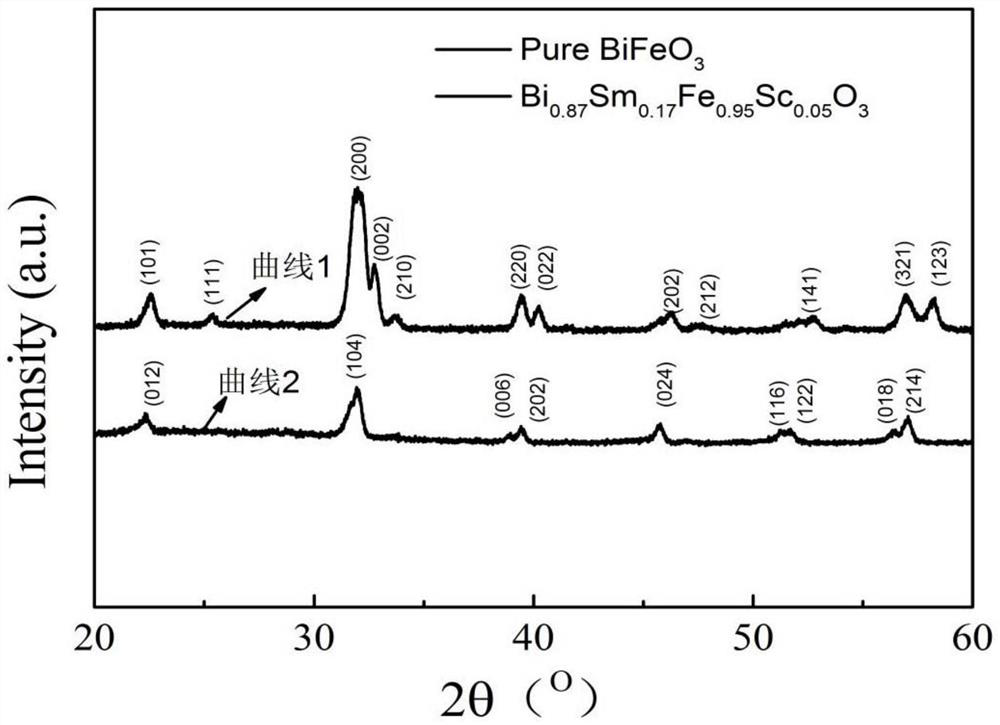

[0062] (1) XRD diffraction test

[0063] see figure 1 , which is the XRD diffraction diagram of the BSFSO ceramic sample and the pure BFO ceramic sample, the curve 1 in the figure is the XRD diffraction diagram of the BSFSO ceramic, and the curve 2 is the XRD diffraction diagram of the pure BFO ceramic. This test result is obtained by X-ray diffractometer (X'Pert PRO, PANalytical) to the BSFSO ceramics test that embodiment 1 makes. From figure 1 It can be seen from the figure that BSFSO ceramics can form independent phases without other impurity phases.

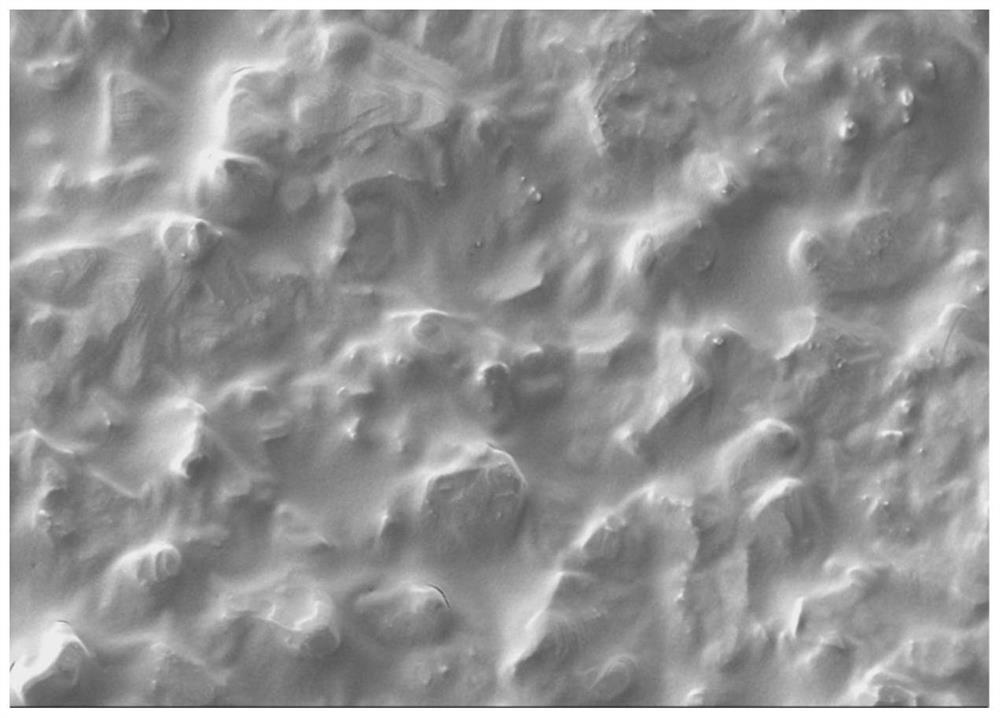

[0064] (2) SEM section characterization

[0065] see figure 2 , which is the SEM cross-sectional characterization diagram and partial enlarged diagram of the BSFSO ceramic sample. The test results are...

PUM

| Property | Measurement | Unit |

|---|---|---|

| energy density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com