A kind of high-purity odorless phycocyanin and its preparation method and application

A high-purity phycocyanin technology, which is applied in the field of separation and purification of phycocyanin, can solve the problems of unsuitability for industrial production, long cycle time, and fishy smell of the product, and achieve improved leaching rate and leaching amount, short extraction cycle, and pigment destruction. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

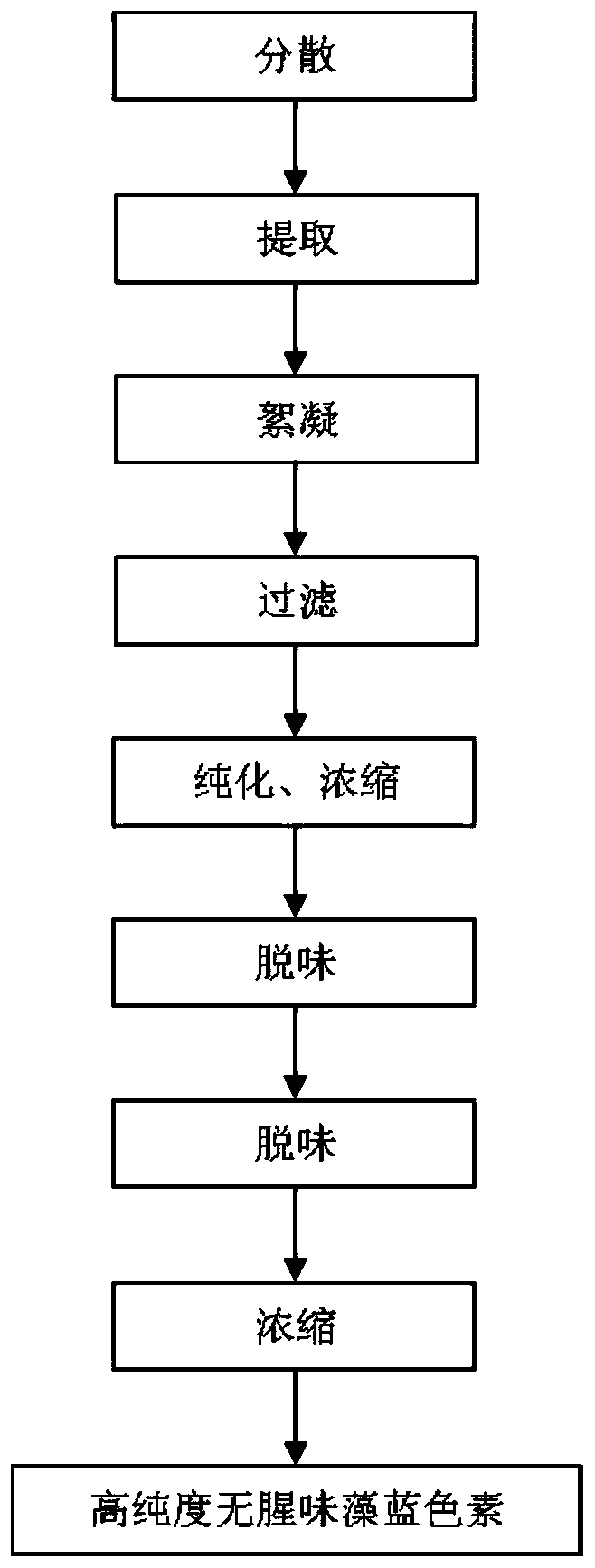

[0073] A preparation method of high-purity odorless phycocyanin, comprising the following steps:

[0074] (1) uniformly mix spirulina and water, disperse at 10-25°C for 2-5 hours, and obtain a spirulina dispersion;

[0075] (2) The spirulina dispersion prepared in step (1) is prepared as a phosphate buffer containing spirulina and the final concentration of phosphate is 0.05~0.12mol / L, under stirring conditions, leaching at 10~25°C for 12~ 18h, obtain spirulina extract;

[0076] (3) adding 0.5~3% of the spirulina extract quality and 8~15% disodium hydrogen phosphate solution in the spirulina extract obtained in step (2), mix uniformly; then add the spirulina Calcium chloride solution with a mass concentration of 2 to 10% and a mass concentration of 15 to 25% is stirred for 10 to 20 minutes; after the stirring is completed and the pH of the system is stable, the pH of the system is adjusted to 7.0 to 7.5 with lye to obtain flocculation After the extract;

[0077] (4) adding ...

Embodiment 1

[0119] (1) Add 46kg of reverse osmosis membrane filter water into a 100L extraction tank, then slowly add 1.5kg of spirulina dry powder into the extraction tank, stir to make it evenly dispersed; then maintain the system at 20°C, stir and disperse for 3 hours to obtain a spirulina dispersion ;

[0120] (2) add disodium hydrogen phosphate (Na 2 HPO 4 12H 2 O) 300.9g and sodium dihydrogen phosphate (NaH 2 PO 4 2H 2 (2) 586.7g, containing spirulina and a phosphate buffer solution with a final concentration of phosphate radicals of 0.1mol / L, under stirring conditions, leaching at 20°C for 15h to obtain a spirulina extract;

[0121] (3) Adding 483.9g mass concentration to the spirulina extract prepared in step (2) is 10% disodium hydrogen phosphate solution, stirs for 8min, makes it mix uniformly; Adds 2903.3g mass concentration 20% chloride Calcium solution, stirred for 15 minutes; after the stirring was completed and the pH value of the system was stable, the pH value of th...

Embodiment 2

[0128] (1) Add 46kg of reverse osmosis membrane filter water into a 100L extraction tank, then slowly add 1.7kg of spirulina dry powder into the extraction tank, stir to make it evenly dispersed; then maintain the system at 22°C, stir and disperse for 2 hours to obtain a spirulina dispersion ;

[0129] (2) add disodium hydrogen phosphate (Na 2 HPO 4 12H 2 O) 179.1g and sodium dihydrogen phosphate (NaH 2 PO 4 2H 2 (2) 349.5g, obtain the phosphate buffer that contains spirulina and the final concentration of phosphate is 0.06mol / L, under stirring condition, 18 ℃ of leaching 18h, obtain spirulina extract;

[0130] (3) Adding 241.1g mass concentration to the spirulina extract obtained in step (2) is a 15% disodium hydrogen phosphate solution, stirs for 5min, and makes it mix uniformly; then adds 4822.9g mass concentration 15% chloride Calcium solution, stirred for 10 minutes; after the stirring was completed and the pH value of the system was stable, the pH value of the syst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com