Microbial inoculum with high salt tolerance and oil degradation rate and preparation method thereof

A microbial agent and salt-tolerant technology, applied in the field of microbial agent and its preparation, can solve the problems of poor product maturity, long fermentation cycle, low degradation rate of food waste oil, etc., and achieve the effect of reducing purchase cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

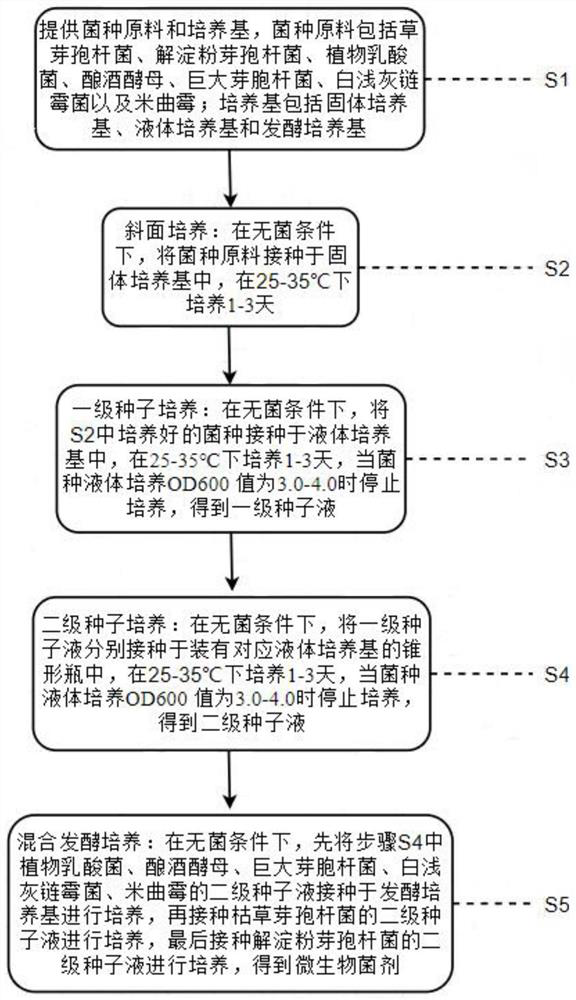

[0038] See figure 1 , the preparation method of the microbial inoculum with high salt tolerance and grease degradation rate of the present invention comprises the following steps:

[0039] S1. Provide strain raw materials and culture medium, strain materials include Bacillus phlei, Bacillus amyloliquefaciens, Lactobacillus plantarum, Saccharomyces cerevisiae, Bacillus megaterium, Streptomyces alba and Aspergillus oryzae; culture medium includes solid medium, liquid Culture medium and fermentation medium, wherein the solid medium includes beef extract peptone agar medium, potato dextrose agar medium and lactic acid bacteria solid medium; liquid medium includes beef extract peptone liquid medium, potato dextrose liquid medium and lactic acid Bacterial liquid culture medium; fermentation medium is: molasses 3%, corn steep liquor powder 8%, magnesium sulfate 0.2%, sodium hydroxide 0.15%, dipotassium hydrogen phosphate 0.1%, potassium dihydrogen phosphate 0.1%, and the balance is w...

Embodiment 1

[0049] S1. Slope culture: under sterile conditions, inoculate Bacillus subtilis, Bacillus amyloliquefaciens and Bacillus megaterium in beef extract peptone agar medium for cultivation, and inoculate plant lactic acid bacteria in lactic acid bacteria solid medium (MRS) Cultivate, inoculate Saccharomyces cerevisiae, Streptomyces alba and Aspergillus oryzae in potato dextrose agar medium (PDA) for cultivation, wherein, plant lactic acid bacteria, Saccharomyces cerevisiae, Bacillus megaterium, Streptomyces alba, Aspergillus oryzae , Bacillus subtilis and Bacillus amyloliquefaciens were cultured at 30℃ for 2 days;

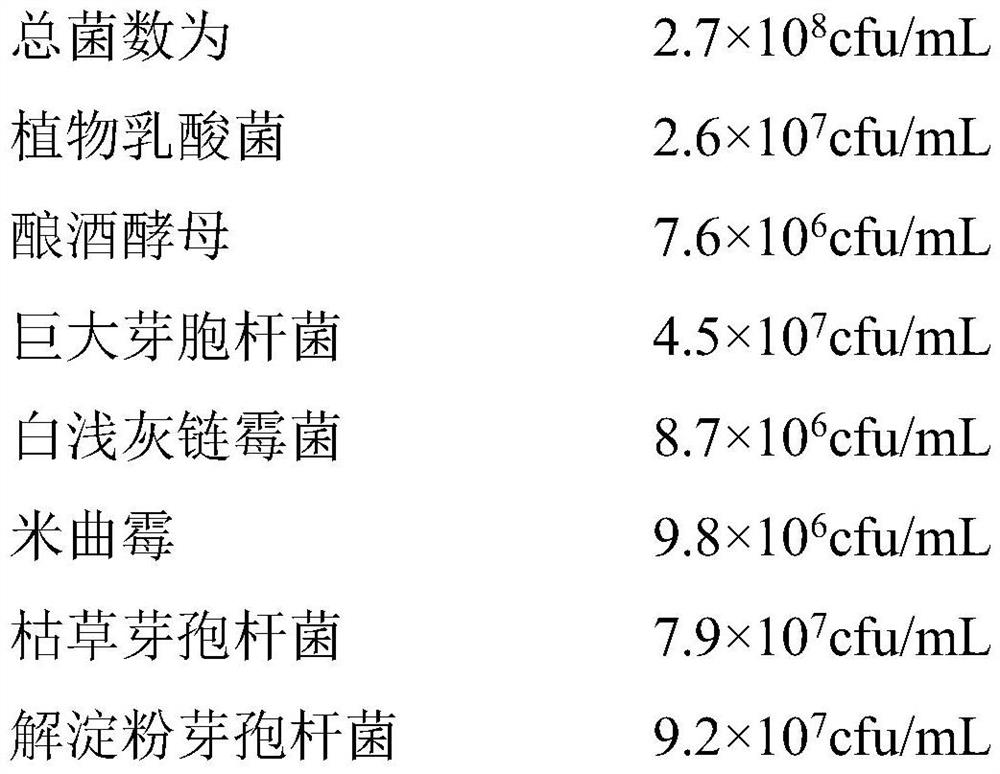

[0050] S2, primary seed culture: the strains cultivated in step S1 are individually picked and inoculated into 50mL / 250mL liquid culture medium under sterile conditions, plant lactobacillus, Saccharomyces cerevisiae, Bacillus megaterium, Streptomyces alba, rice Aspergillus was cultured for 2 days under the condition of 30℃, 160r / min shaker, Bacillus subtilis and Bacillu...

Embodiment 2

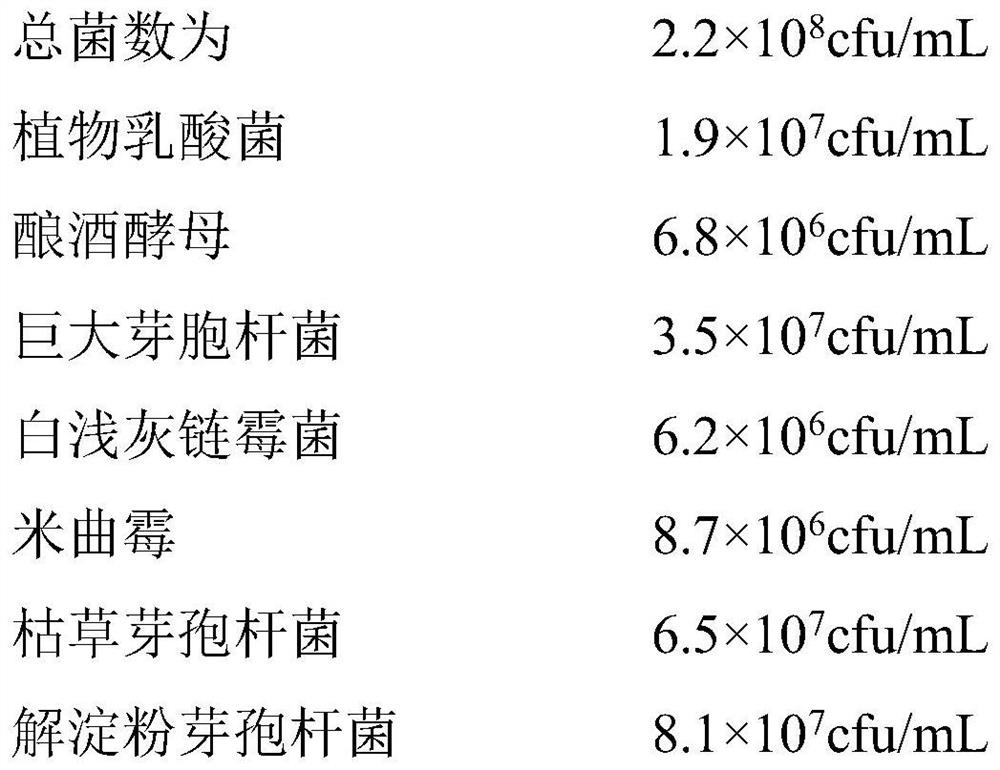

[0056] The preparation method of the present embodiment is basically similar to that of the first embodiment, and the difference lies in that the inoculation amount in step S3 is changed from 5% to 4% to obtain the high-salt and high-fat kitchen waste treatment microbial inoculum of the present embodiment. The bacterial composition is:

[0057]

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap