A technology for preparing mushroom nutrition bowl by steam explosion technology of biogas residue

A nutrient bowl and steam explosion technology, which is applied in the field of producing mushroom nutrient bowls using biogas residue steam explosion technology, to achieve the effects of short production cycle, less bacteria and high output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

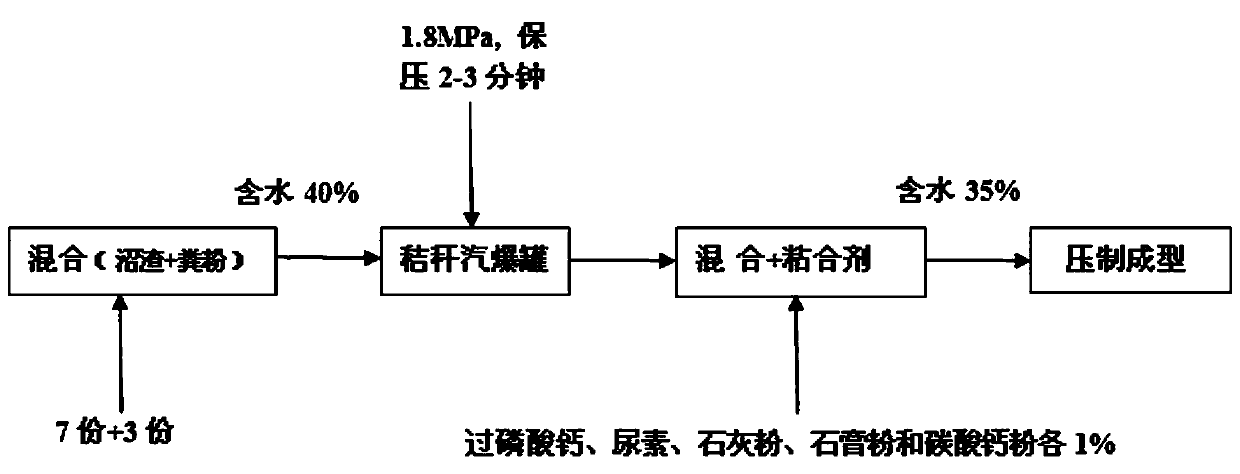

[0021] The process of utilizing biogas slag steam explosion technology of the present embodiment to produce mushroom nutrition bowl, the steps are as follows:

[0022] (1) Mix the fresh biogas residue with the air-dried manure powder at a ratio of 7:3, keep the water content of the raw material at about 40% after mixing, transport it to the steam explosion tank, and seal it and inject saturated steam;

[0023] (2) Keep the pressure of the steam explosion tank at 1.8MPa, the pressure holding time is 2 minutes, and then explode;

[0024] (3) The raw materials after blasting are transported to the mixing tank by screw conveyor in time, and then mixed with superphosphate, urea, lime powder, gypsum powder and calcium carbonate powder, each accounting for 1% of the total mass of biogas residue and manure powder, and adding Accounting for 1.5% of the total mass of biogas residue and manure powder, the moisture content is controlled at about 35%, and finally, pressed into shape; where...

Embodiment 2

[0026] The process of utilizing biogas slag steam explosion technology of the present embodiment to produce mushroom nutrition bowl, the steps are as follows:

[0027] (1) Mix the fresh biogas residue with the air-dried manure powder at a ratio of 7:3, keep the water content of the raw material at about 40% after mixing, transport it to the steam explosion tank, and seal it and inject saturated steam;

[0028] (2) Keep the pressure of the steam explosion tank at 1.8MPa, the pressure holding time is 3 minutes, and then explode;

[0029] (3) The raw materials after blasting are transported to the mixing tank by screw conveyor in time, and then mixed with 1% each of superphosphate, urea, lime powder, gypsum powder and calcium carbonate powder, and add adhesive to control the moisture content at 40 % or so, and finally, compression molding.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com