Yarn cooking device and processing method for processing yarn-dyed four-way stretch fabric

A four-way elastic and boiled yarn technology is applied in the processing of textile material equipment configuration, textile material carrier processing, and spray/jet textile material processing. It can solve problems such as single color, achieve simple steps, improve processing efficiency, and improve stability. and reliability effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

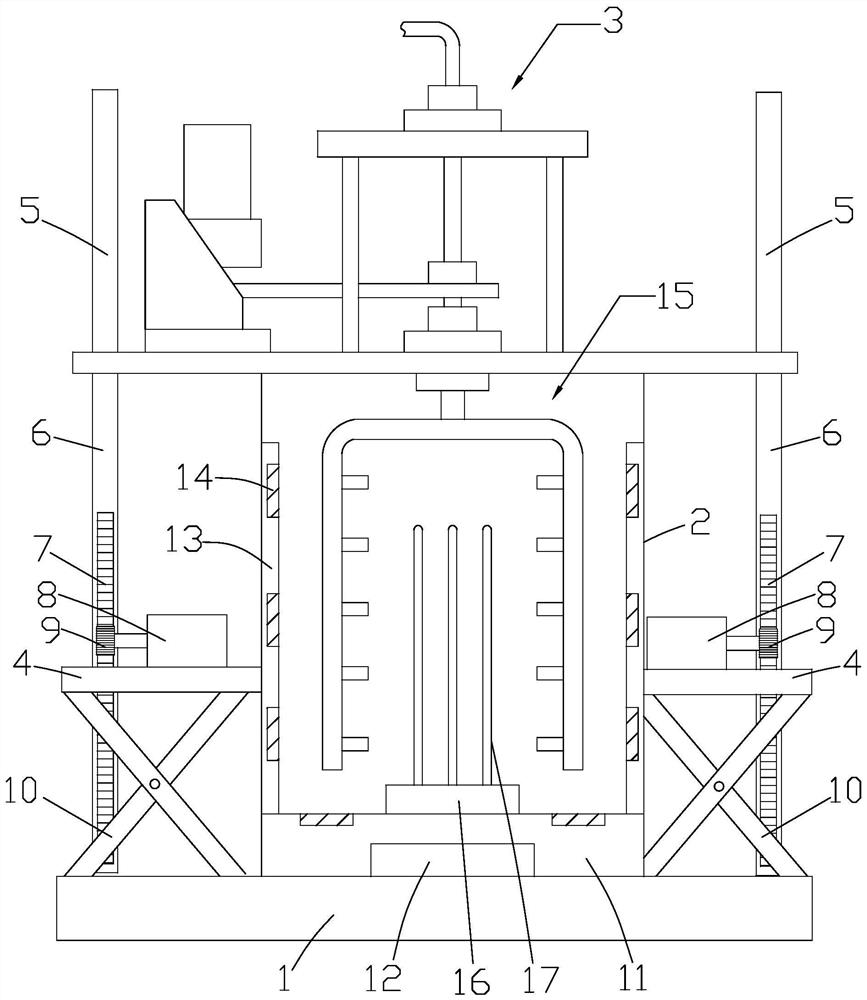

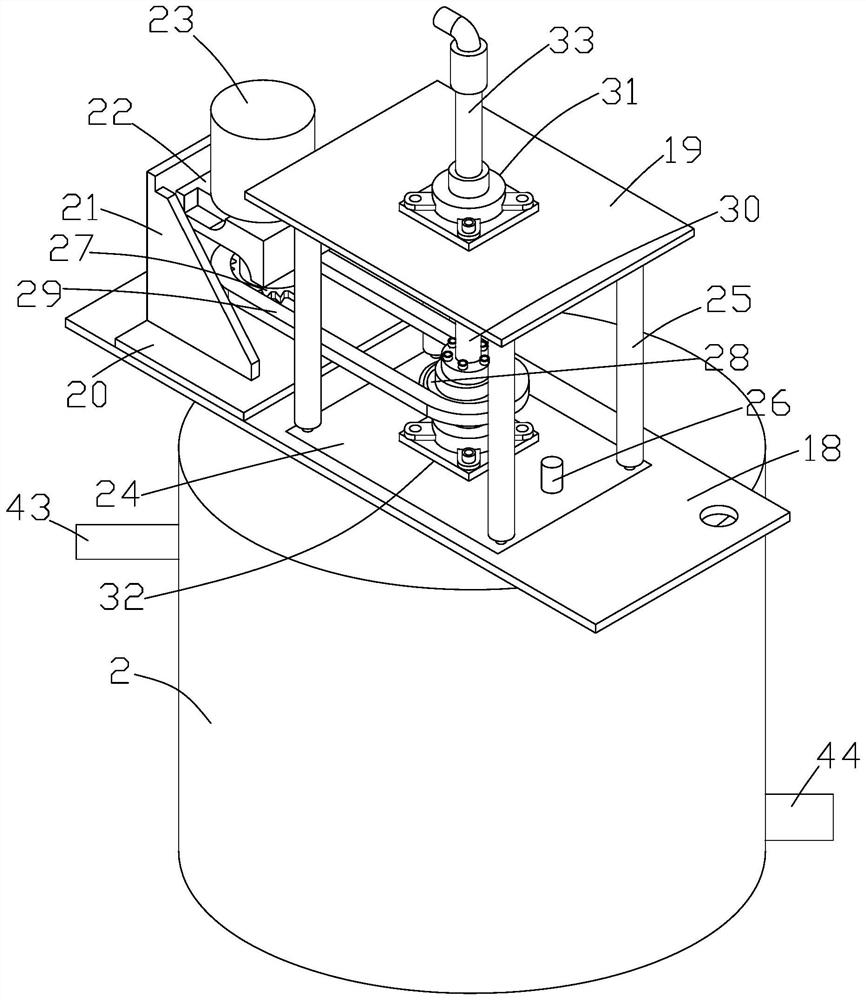

[0043] Such as Figure 1 to Figure 4 As shown, it is a yarn cooking device for processing yarn-dyed four-way stretch fabrics of the present invention, including a barrel body 2, a driving device 3, a first base 1 and a lifting mechanism, and the barrel body 2 is fixedly connected to the top surface of the first base 1 A water inlet pipe 43 and an outlet pipe 44 are arranged on the outer surface of the barrel body 2, the water inlet pipe 43 is located above the water outlet pipe 44, an inner tank 13 and a second base 11 are arranged in the barrel body 2, and the second base 11 is located in the barrel body 2, the inner container 13 is located on the inner wall of the staving 2, the second base 11 and the inner container 13 are provided with a heating plate 14, and the second base 11 is provided with a storage battery 12.

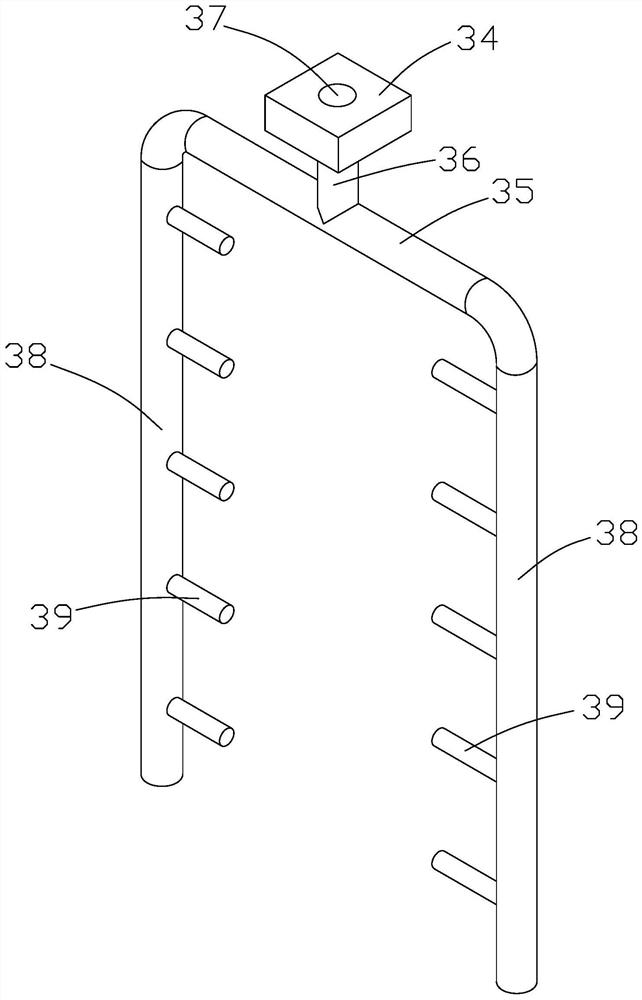

[0044] The top of the second base 11 is provided with a yarn fastening device, and the yarn fastening device includes a positioning plate 16 and at least thr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com