High-strength concrete-filled steel tube strut for coal mining and use method of strut

A technology of steel pipe concrete and steel pipe columns, which is applied in the direction of pillars/brackets, mining equipment, earthwork drilling and mining, etc. It can solve the problems of low bearing capacity of hydraulic pillars, achieve high support pressure, realize support pressure, and improve the effect of force conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

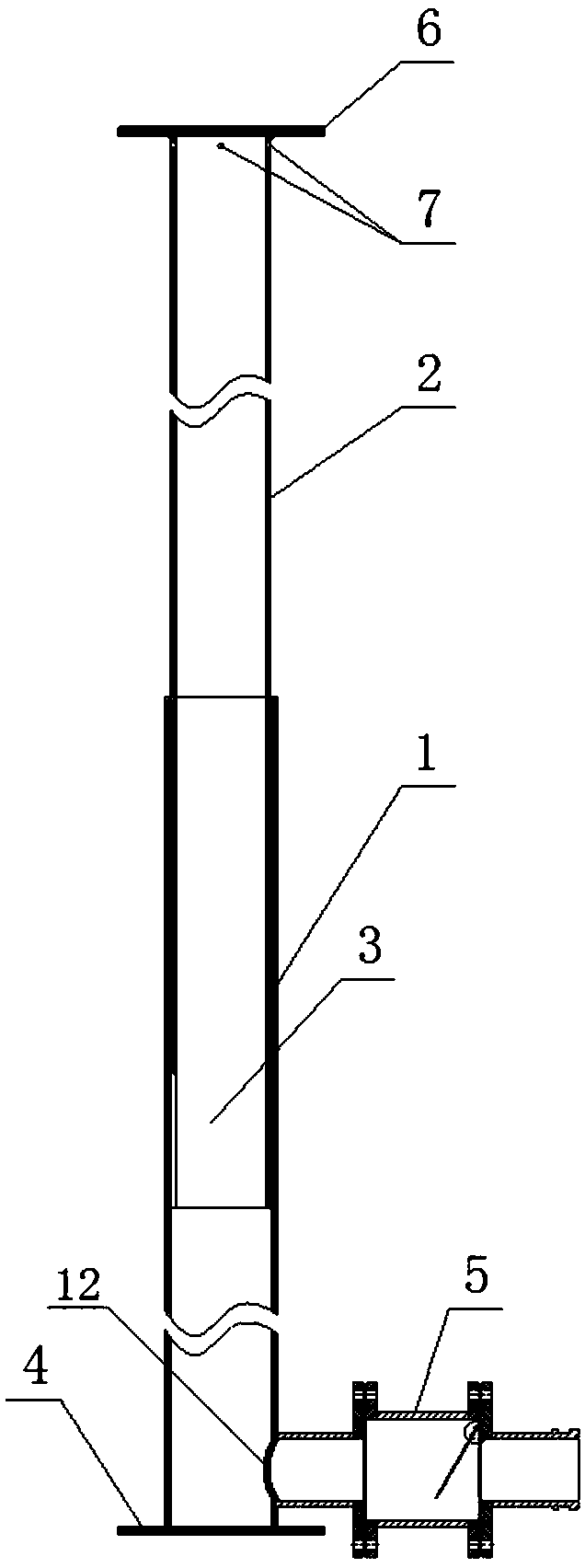

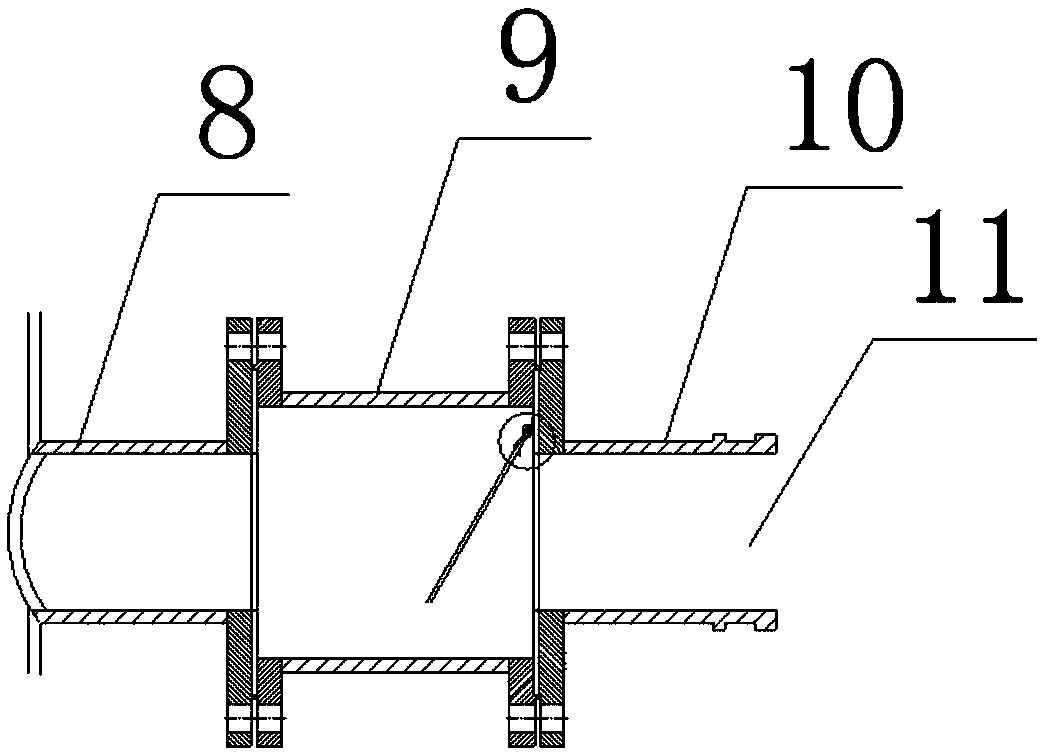

[0025] like figure 1 As shown, the present invention includes a lower steel pipe column 1, an upper steel pipe column 2, a column shoe 4, a column cap 6 and a one-way stop valve 5, and both the lower steel pipe column 1 and the upper steel pipe column 2 are seamless The steel pipe, the lower end of the upper steel pipe column 2 is nested into the lower steel pipe column 1, the length of the upper steel pipe column 2 nested inside the lower steel pipe column 1 is 1 / 6 to 1 / 2 of the total length of the upper steel pipe column 2, and can be Move up and down; the lower end of the lower steel pipe column 1 and the column shoe 4 are sealed and welded together, so that on the one hand, it acts as a seal, and on the other hand, it can also disperse the pressure distribution of the concrete pillar on the ground, preventing the pillar from losing its load due t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com