Transportation vehicle hydraulic system

A technology for hydraulic systems and trucks, applied in fluid pressure actuators, servo motors, servo meter circuits, etc., which can solve the problems of increased manufacturing costs, high prices, and long lead times for vulnerable parts, ensuring smooth loading and unloading , Guarantee the stability and avoid the effect of falling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

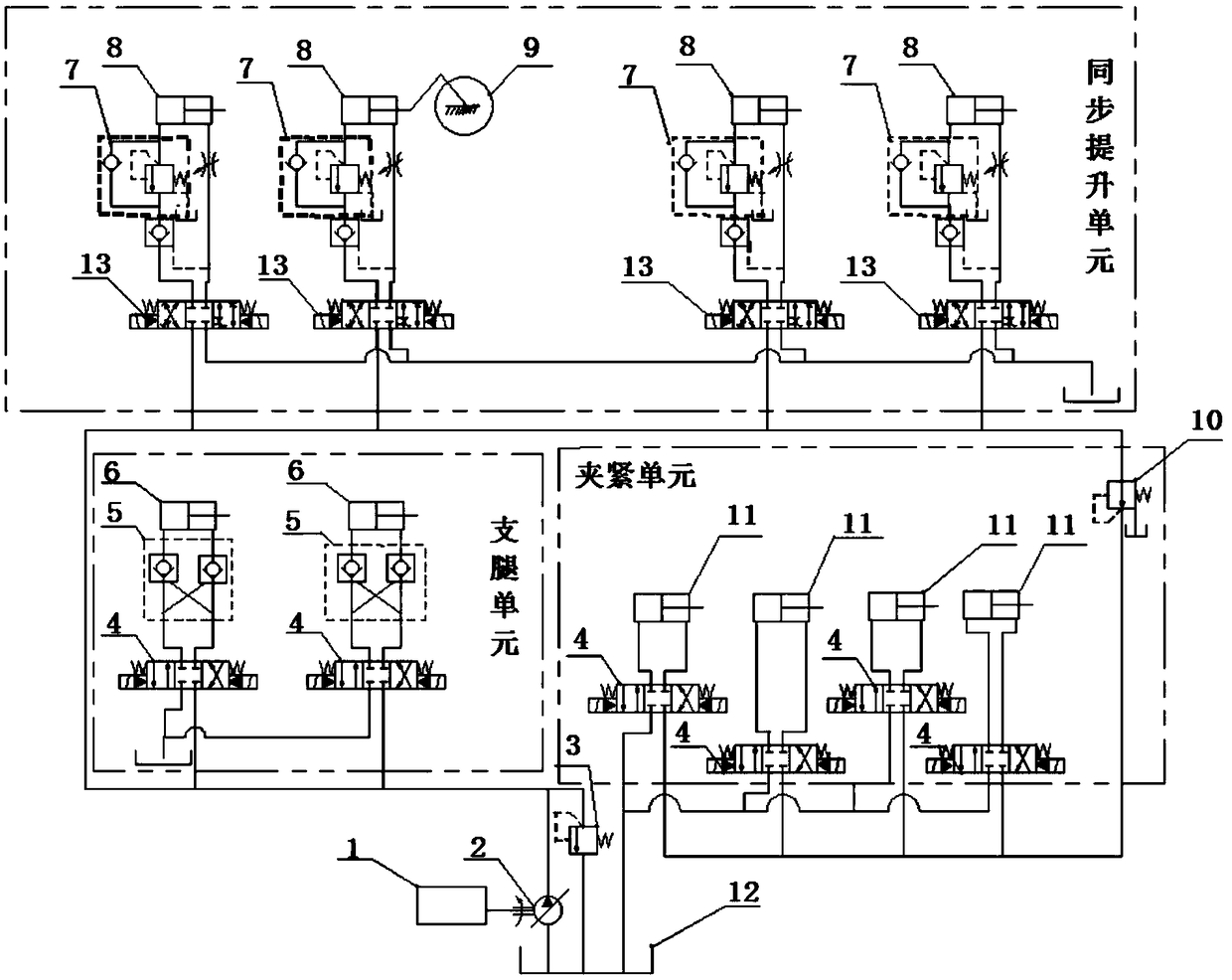

[0018] Such as figure 1 As shown, a truck hydraulic system includes an oil supply circuit, a synchronous lifting unit, an outrigger unit and a clamping unit, and the outrigger unit, a synchronous lifting unit and a clamping unit are sequentially arranged on the oil supply circuit, A first decompression circuit with a first decompression valve connected in series flows out from the clamping unit and the lifting unit, and a second decompression circuit connected with a second decompression valve in series flows out from the oil supply circuit and the outrigger unit.

[0019] The outrigger unit includes two identical outrigger control circuits, and the two outrigger control circuits are sequentially separated from the oil supply circuit, and the three-position four-way reversing valve and the frame car are sequentially arranged on the outrigger control circuit. Outrigger hydraulic lock, the two inlets and outlets of the frame car outrigger hydraulic lock are respectively connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com