A metal material uniaxial creep resistance test sample, fixture and method

A technology of metal materials and test methods, applied in the direction of analyzing materials, using stable tension/compression to test the strength of materials, instruments, etc., can solve the problem that the accuracy and precision need to be improved, the stability of the clamping test needs to be improved, and it cannot be tested Compressive creep and other issues, to achieve the effect of high accuracy, high test efficiency and simple test method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

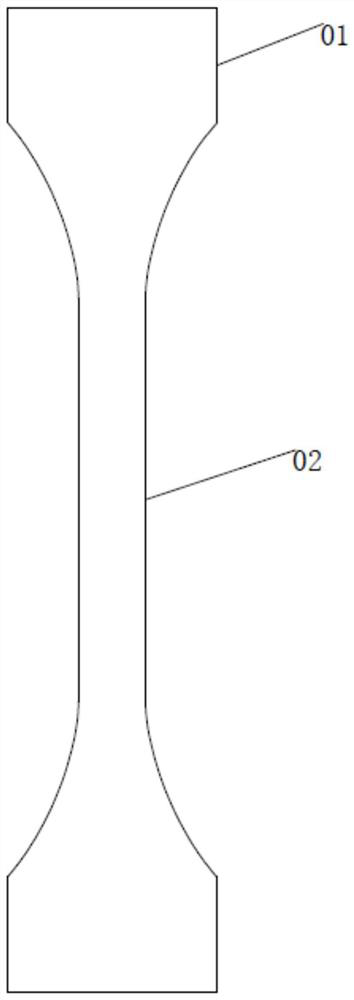

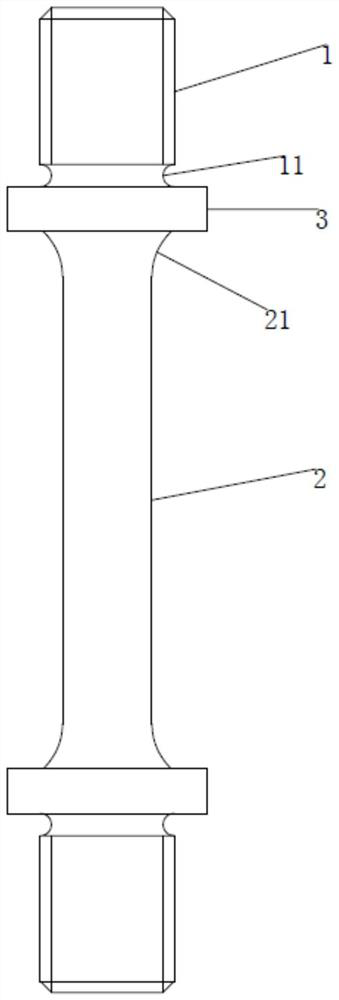

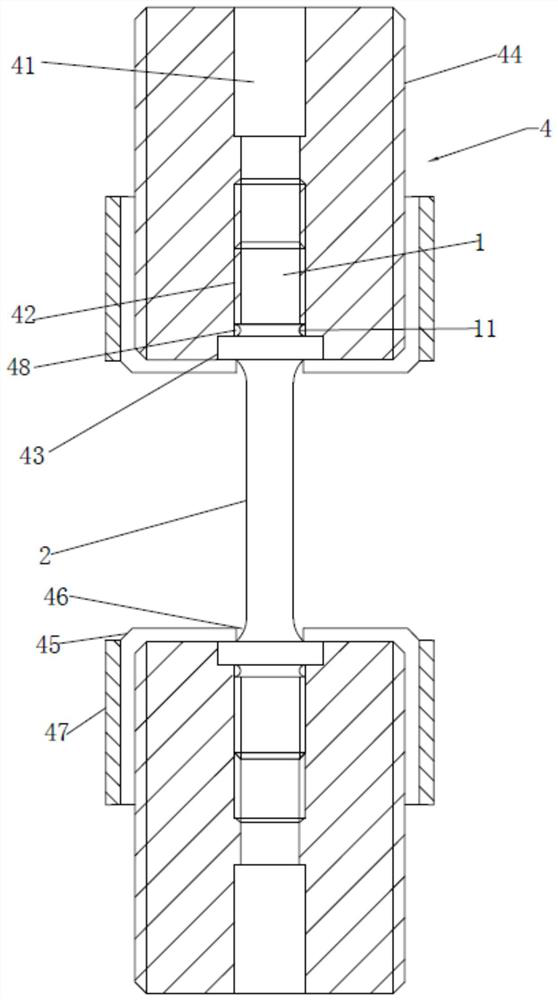

[0054] A metal material uniaxial creep test specimen, such as figure 2 As shown, it includes the test part 2 and the clamping part 1 integrally formed with the two ends of the test part 2. The connection between the test part 2 and the clamping part 1 is surrounded by a boss 3. The central axis of the center axis coincides, and the diameter of the cross section increases sequentially; the clamping part 1 is provided with a screw thread connected with the test fixture 4; the connecting boss 3 of the clamping part 1 is provided with a groove 11, and the groove 11 is connected with the fixture Raised ring 48 in 4 (see image 3 ) are snapped together. The cross-sectional diameter of the test part 2 is 4.5-5 mm, and the cross-sectional diameter of the boss 3 is 2-2.5 times of the cross-sectional diameter of the test part 2 . The radius of the concave arc of the groove 11 is 0.6-0.7 mm, and the junction of the test part 2 and the boss 3 forms an arc 21 transition, and the radius ...

Embodiment 2

[0056] A metal material uniaxial creep resistance test fixture 4, including a clamping hole 42 for clamping the clamping part 1 of the metal material uniaxial creep resistance test sample in Example 1, and the clamping hole 42 is provided with The thread matched with the thread of the clamping part 1 is used to insert the insertion hole 43 of the boss 3; the connection between the clamping hole 42 and the insertion hole 43 is provided with a convex ring 48 that snaps into the groove 11; on the clamp 4 A pilot hole 41 coaxial with the insertion hole 43 is also provided for centering with the testing machine.

[0057] The sample in Example 1 is used in conjunction with the fixture 4 in Example 2, the matching is higher, and the test data is more accurate.

[0058] The clamp 4 fixes the clamping part 1. When the tensile creep of the test sample needs to be tested, the threaded connection is better for clamping, and it is not easy to slide during the test, and the test result is m...

Embodiment 3

[0062] A metal material uniaxial creep resistance test method, comprising a compressive creep test and a tensile creep test;

[0063] Compressive creep involves the following steps:

[0064] S1 The metal material uniaxial creep resistance test sample in embodiment 1 is vertically installed between the upper and lower two metal material uniaxial creep resistance test fixtures in embodiment 2 of the creep endurance test machine, and the sample is adjusted so that it is vertically The axis coincides with the longitudinal axis of the pressure plate;

[0065] S2 Heating the sample to the specified test temperature;

[0066] S3 Apply the test force in the axial direction of the sample;

[0067] S4 When the load corresponding to the test force is fully applied on the sample, the creep test starts and the creep deformation is recorded, the compressive creep test is performed, and the data is recorded.

[0068] The procedure for tensile creep is the same as for compressive creep, bu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com