Rapid detection method for concrete temperature rise

A detection method and concrete technology, which is applied in the direction of measuring devices, material inspection products, instruments, etc., can solve the problems of inability to respond to the internal temperature rise of concrete, and achieve the effect of fast test data, small workload, and elimination of influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

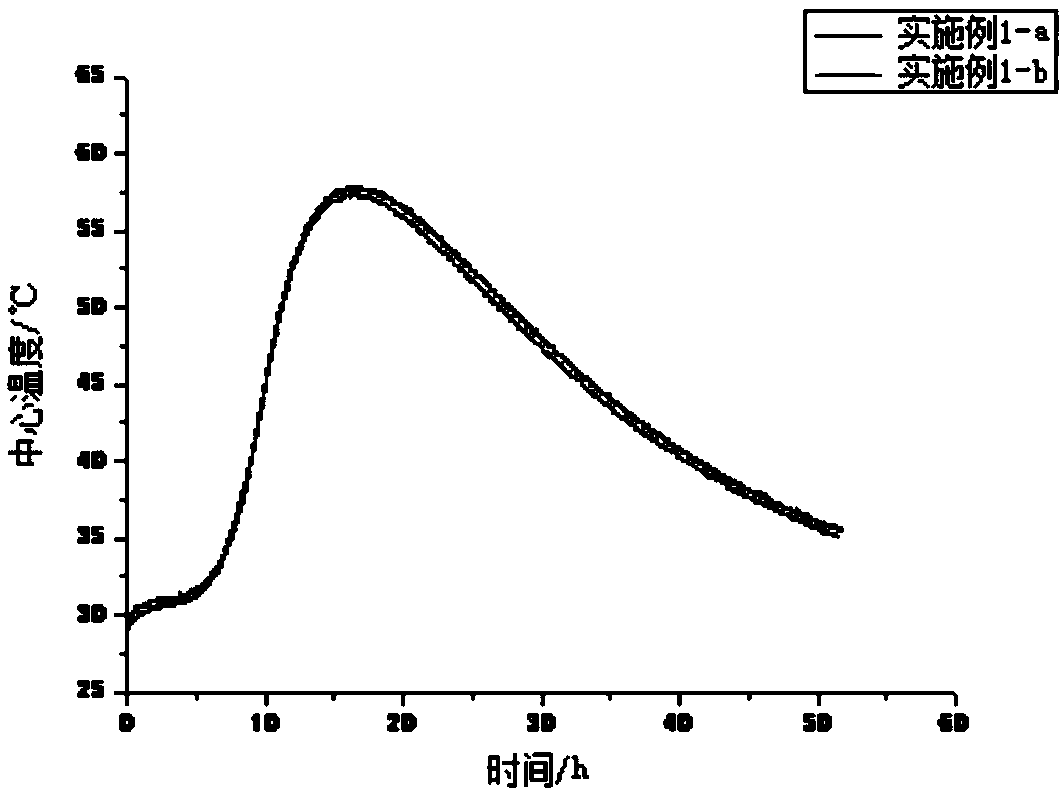

Embodiment 1

[0051] The concrete used in this example has a strength grade of C50, and the concrete mix ratio is shown in Table 1. The addition method is to mix with cementitious material, admixture, and coarse and fine aggregate first, then add water and water reducing agent, and mix The combined time is not less than 150 seconds, the concrete slump is controlled at 200±20mm, and two data lines are buried at the center of the concrete at the same time. The detection starts after the concrete is completely put into the mold, and the detection frequency is 2 times / min. Since the formwork is usually removed at about 24 hours during the construction of the project site to form heat dissipation conditions, in order to be close to the site, the insulation material on the top of the thermal insulation mold for the test was removed when the concrete was put into the mold for 24 hours. The temperature rise curve drawn is as figure 1 shown.

[0052] Table 1 Example 1 concrete mix ratio

[0053] ...

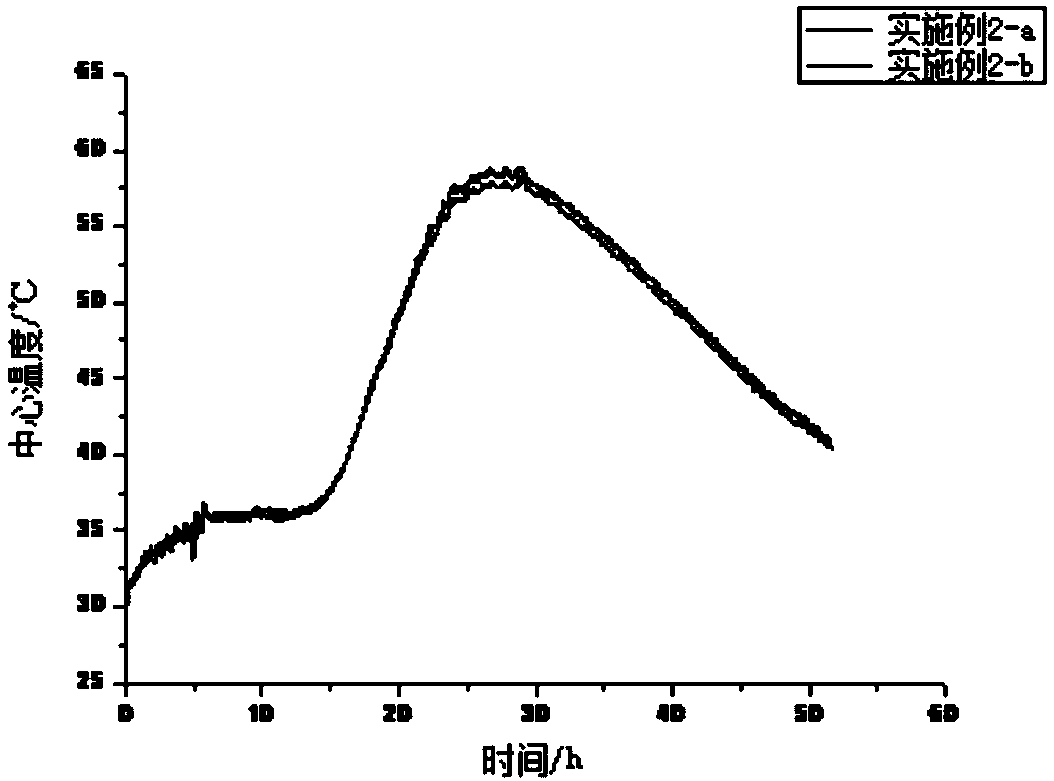

Embodiment 2

[0055] The concrete used in this embodiment is basically the same as in Example 1, except that a commercially available retarder I (phosphates) is added to the raw materials, and the amount added is 0.07% of the total amount of cementitious materials. The temperature rise curve drawn is as figure 2 shown.

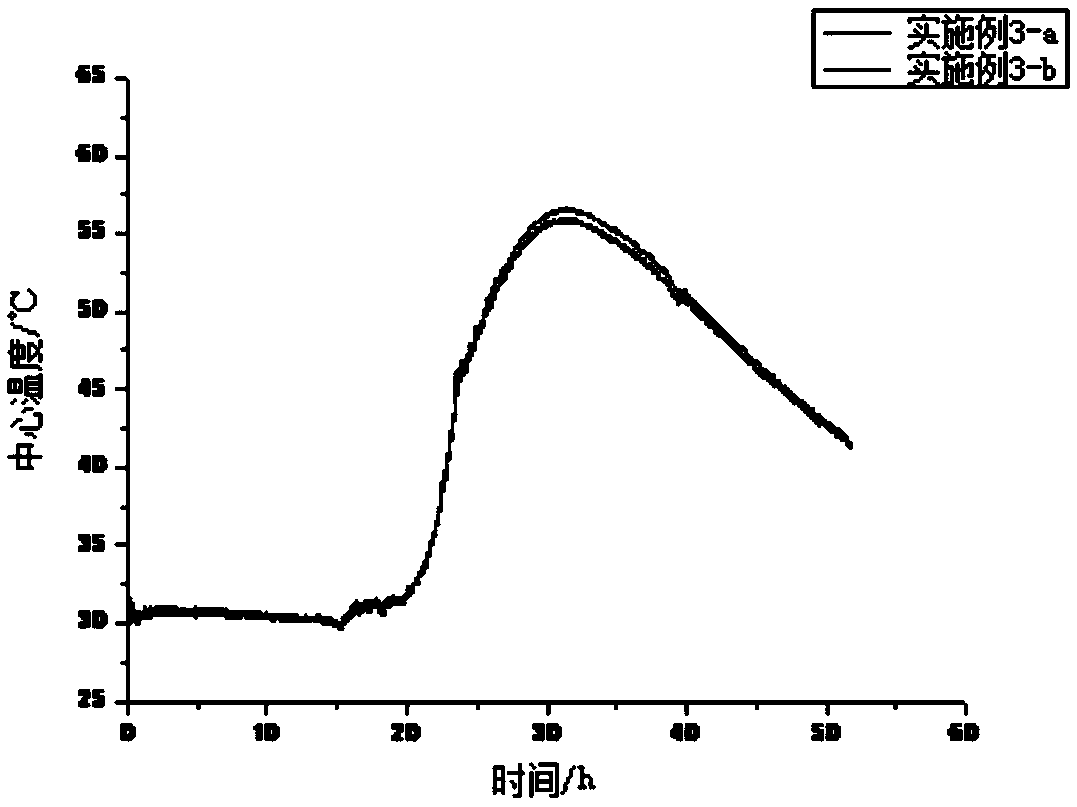

Embodiment 3

[0057] The concrete used in this embodiment is basically the same as that in Embodiment 1, except that a commercially available retarder I (glucose) is added to the raw materials, and the amount added is 0.07% of the total amount of cementitious materials. The temperature rise curve drawn is as image 3 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com