A method for predicting the quality change of frozen pork during storage

A frozen pork, quality technology, applied in the field of meat food testing, can solve the problems of unpredictable precision, long time-consuming, complicated process, etc., and achieve the effect of fast detection, short time-consuming and high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be described in detail below in conjunction with specific embodiments.

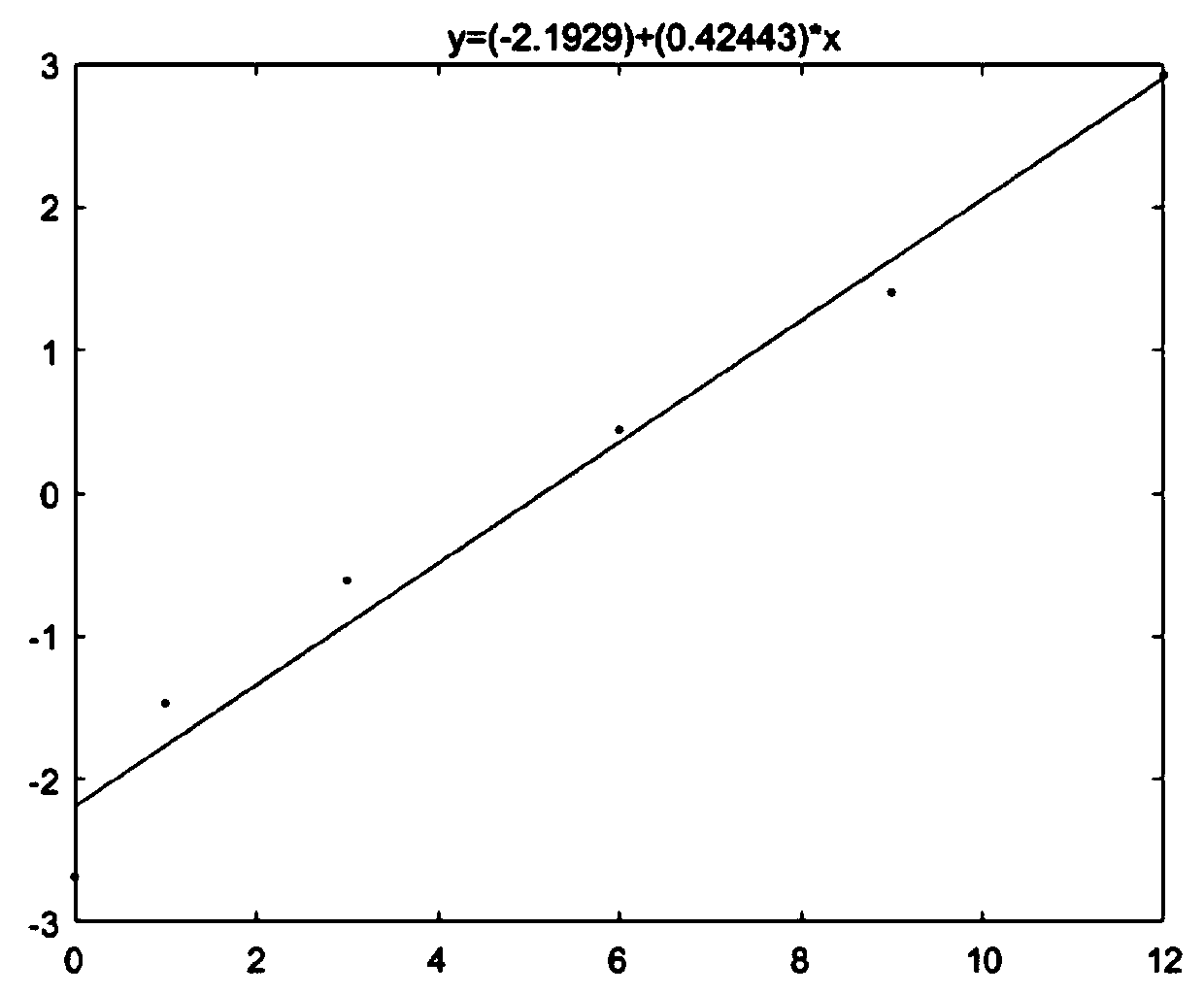

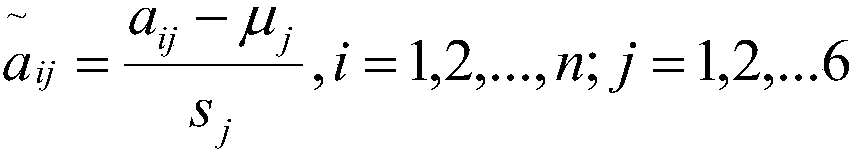

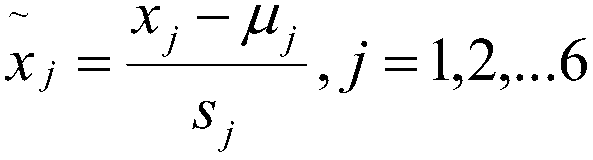

[0048] 1. Establishment of principal component analysis model

[0049] Determination of TVB-N, TBARS, protein solubility, juice loss rate, total amino acid loss rate, T 22 (6 indicators), each data was measured in three groups in parallel, and the average values were respectively shown in Table 1. The 6 indicators and 6 evaluation objects were substituted into the model, and the standardized variables, correlation coefficient matrix, and correlation coefficient matrix were calculated in sequence. Eigenvalues, eigenvectors, contribution rates of principal components, principal component analysis results, and comprehensive evaluation values are shown in Tables 2 to 8, respectively.

[0050] Table 1 The physical and chemical properties of pork tenderloin after thawing

[0051]

[0052] Table 2 Standardized variables

[0053]

[0054]

[0055] Table 3 Correlat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com