Calculation method of gravity tool surface angle of inclinometer while drilling based on MEMS accelerometer with small range

A technology of acceleration sensor and inclinometer while drilling is applied in the field of petroleum drilling engineering, which can solve the problems of large vibration and inability to measure the gravity tool face angle, and achieves the effect of reducing the system cost, improving the promotion value and ensuring the accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

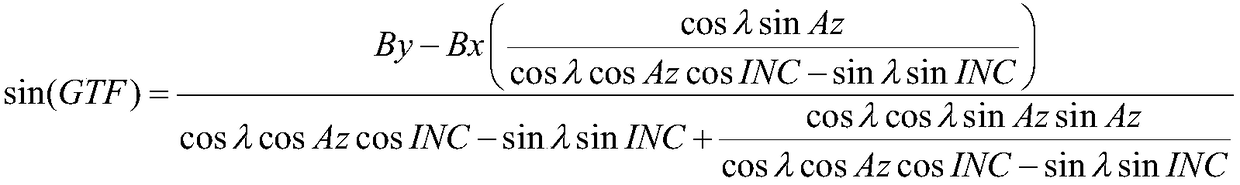

[0031] Embodiment 1, this embodiment provides a method for calculating the gravity tool face angle of an inclinometer while drilling based on a small-range MEMS acceleration sensor

[0032] First of all, in order to ensure the accuracy of the collected data, in this embodiment, the small-range MEMS acceleration sensor and the fluxgate on the exploration-while-drilling inclinometer meet the requirements of room temperature, the sensitivity of the acceleration sensor is less than 1mg, and the sensitivity of the fluxgate is less than 5nT. In this way, the sensor section is composed of a small-range MEMS acceleration sensor and a fluxgate.

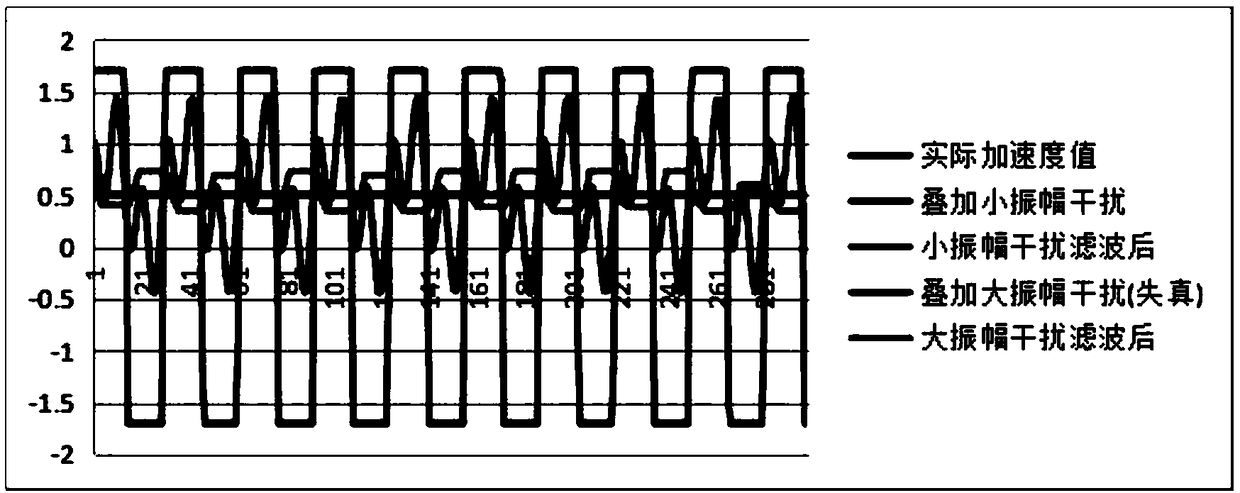

[0033] Then, the data of well inclination (INC), azimuth (Az) and magnetic inclination (λ) are collected and preserved under static working conditions. In this embodiment, a certain type of MEMS acceleration sensor is selected, and the range of this sensor is ± 1.7g ( g is the unit of gravitational acceleration), built-in moving average digita...

Embodiment 2

[0059] Embodiment 2, this embodiment provides a method for calculating the gravity tool face angle of an inclinometer while drilling based on a small-range MEMS acceleration sensor

[0060] Compared with Embodiment 1, in this embodiment, the time period is selected as 5s, and the collected data obtained are as follows:

[0061] Table 3, data of acceleration sensor (Gx, Gy) and fluxgate (Bx, By) in units of 5s under directional drilling conditions

[0062]

[0063]

[0064] After calculation, the obtained data are as follows:

[0065] Table 4. Calculation data of gravity toolface angle at 5s time interval during bottom hole directional drilling

[0066]

[0067]

[0068] Through data verification, it can be clearly seen that the error of the method provided in this embodiment is between ±0.1°, and the data calculation is accurate.

Embodiment 3

[0069] Embodiment 3, this embodiment provides a method for calculating the gravity tool face angle of an inclinometer while drilling based on a small-range MEMS acceleration sensor

[0070] Compared with Embodiment 1 and Embodiment 2, in this embodiment, the time period is selected as 10s, and the acquired data is as follows:

[0071] Table 5, data of acceleration sensor (Gx, Gy) and fluxgate (Bx, By) in units of 10s under directional drilling conditions

[0072]

[0073] After calculation, the obtained data are as follows:

[0074] Table 6. Calculation data of gravity tool face angle at 10s time interval during bottom hole directional drilling

[0075]

[0076]

[0077] Through data verification, it can be clearly seen that the error of the method provided in this embodiment is between ±0.1°, and the data calculation is accurate.

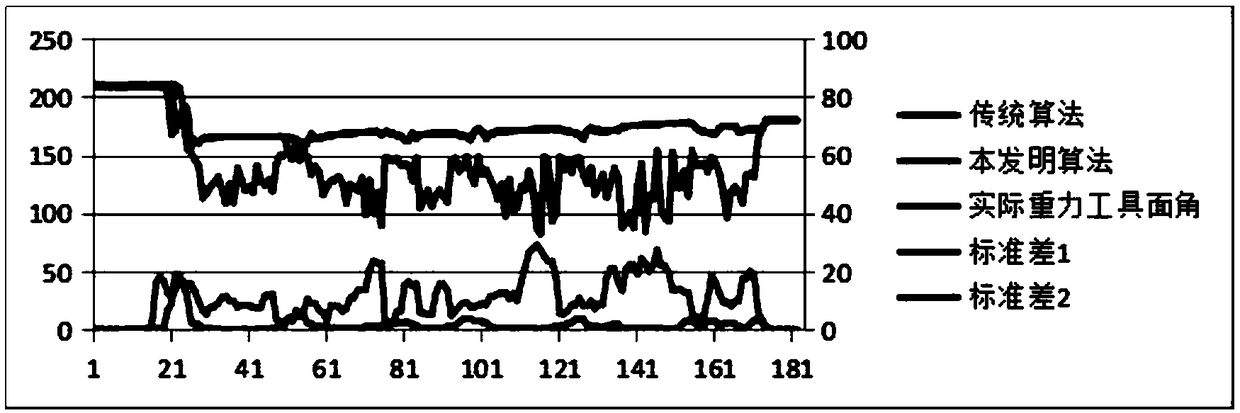

[0078] In summary, the method provided by the present invention can accurately calculate the actual gravity tool face angle, and effect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com