Method for predicting the risk of corrosion and fracture of cable-stayed bridges

A prediction method and sling technique, applied in the field of bridges, can solve the problems that the accuracy of detection instruments cannot reach a relatively accurate prediction, it is difficult to determine the critical corrosion depth, and the workload of key parameters is large, so as to achieve reliable quantitative risk results and improve prediction. control capability and emergency response level, and the effect of reducing casualties and property damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

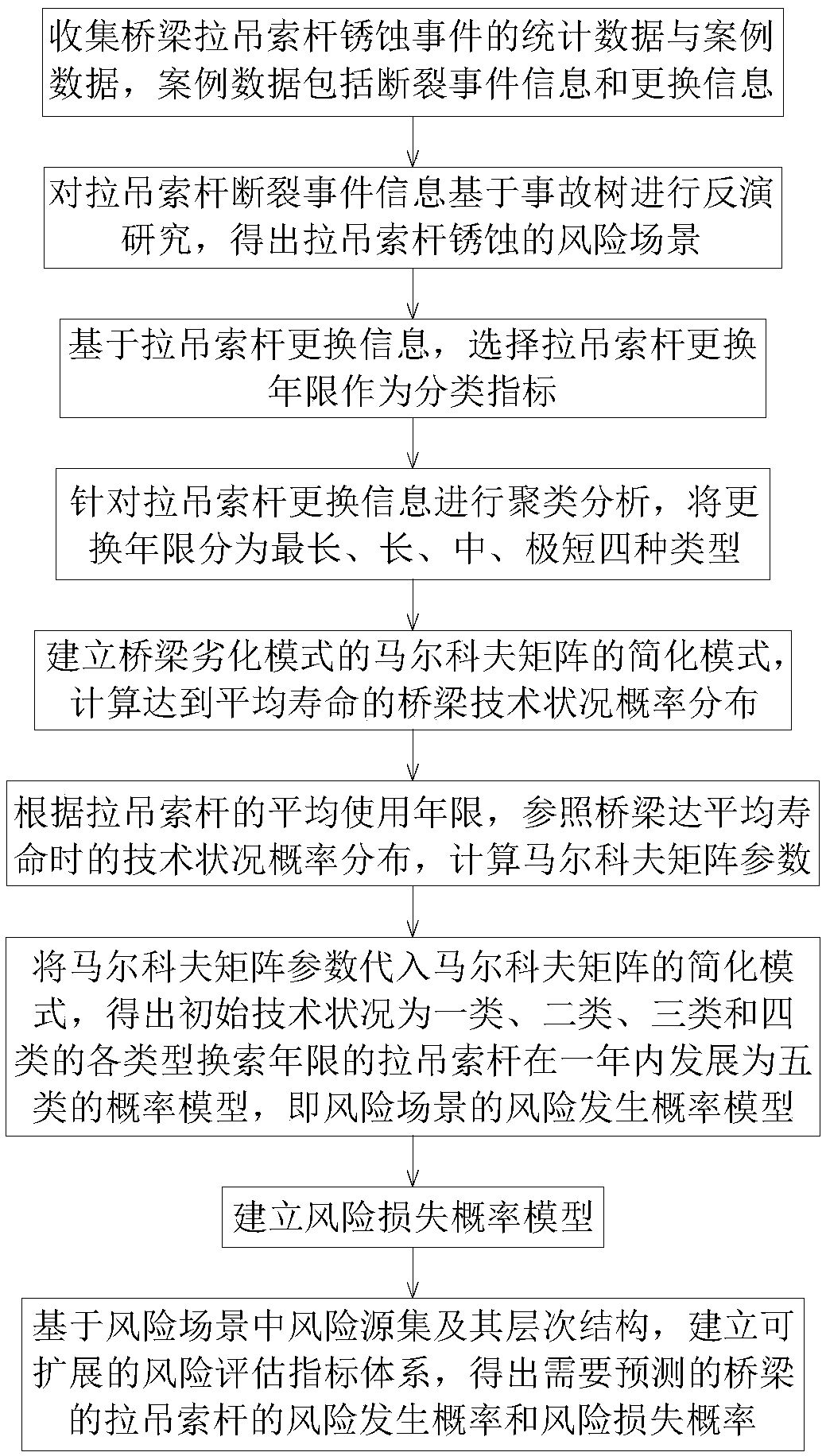

[0050] Such as Figure 1-6 As shown in the present invention, a method for predicting the risk of corrosion and fracture of a bridge pull sling bar comprises the following steps:

[0051] S1. Collect information on the deterioration of the technical condition of bridges in my country's bridge library, archive information on decommissioned bridges, statistical data and case data on the incidents of corrosion and fracture of suspension rods. The case data includes information on the deterioration of technical conditions of 809 bridges and 357 decommissioned bridges Archive information, information on 18 incidents of corrosion and breakage of bridge pull and hanger rods, and information on 53 bridge pull and hanger rod replacements;

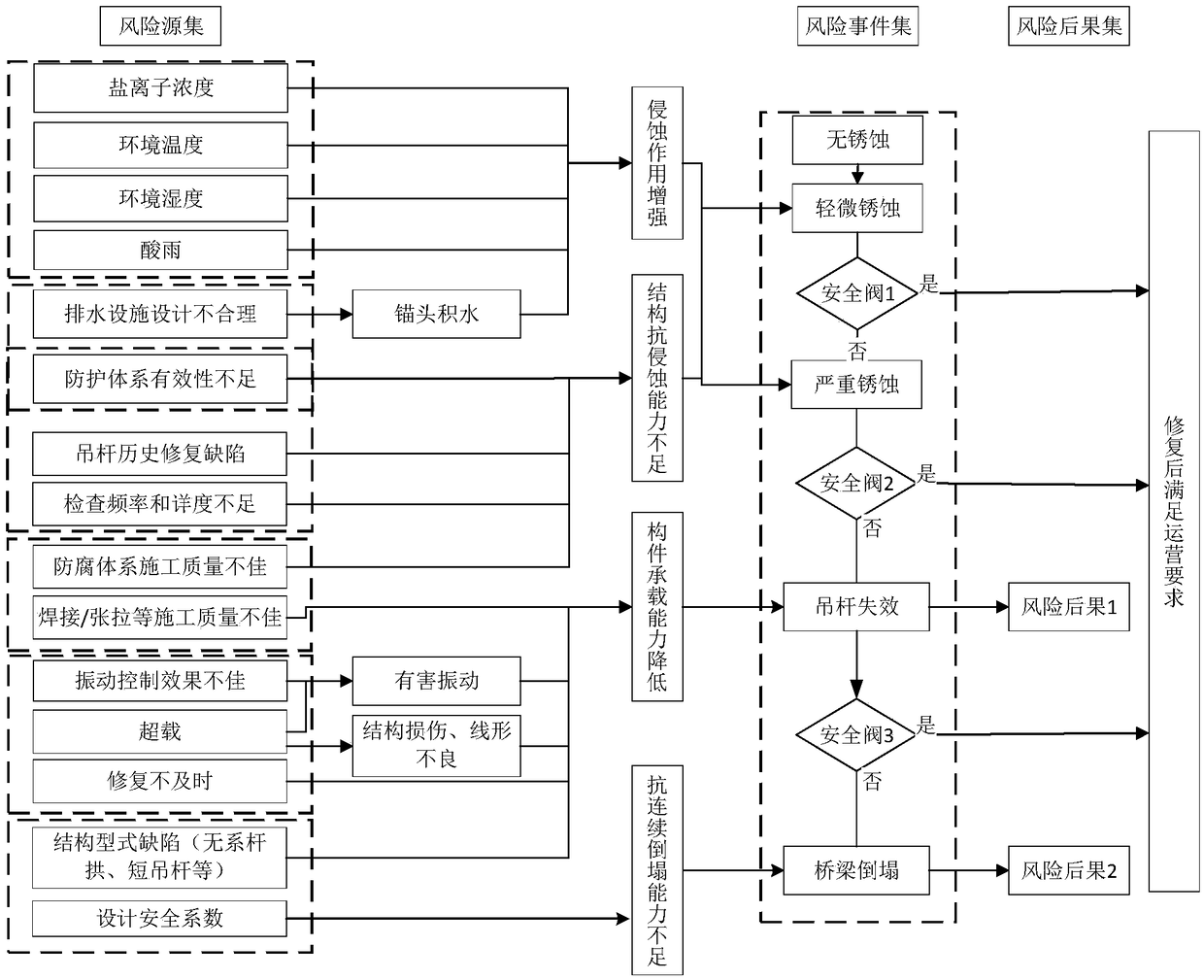

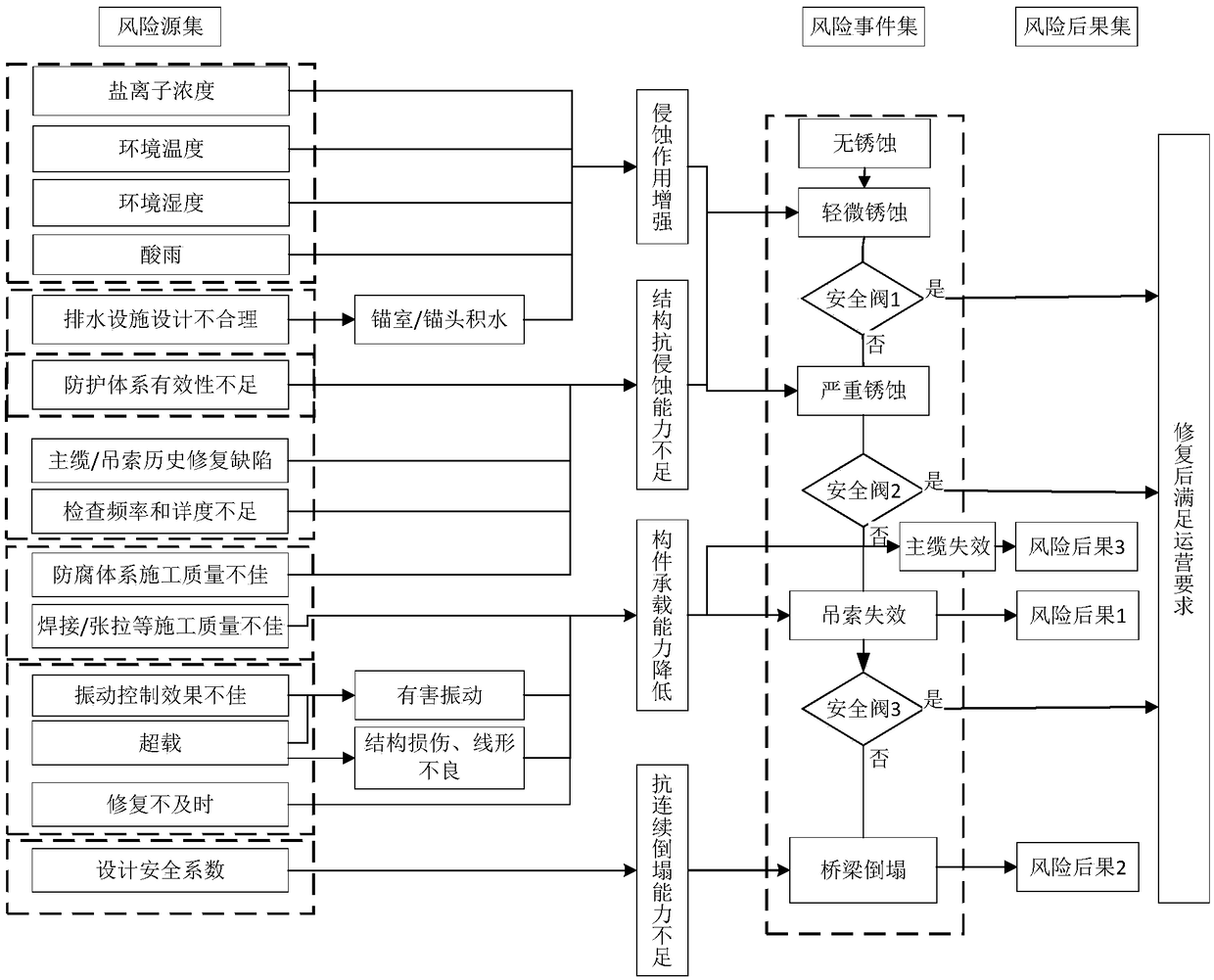

[0052] S2. Carry out an inversion study on the breakage event information of the pulling sling rod based on the fault tree, and draw a risk scenario map of the corrosion of the pulling sling rod, as Figure 2-4 As shown, different risk scenario diag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com