A method for real-time detection of weld seam targets

A real-time detection and target technology, applied in neural learning methods, image data processing, image enhancement, etc., can solve problems such as poor robustness and inaccurate positioning of welding starting points, and achieve simple operation, simple structure, and accurate positioning effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The purpose of the present invention will be further described in detail through specific implementation methods below, and the embodiments cannot be repeated here one by one, but the implementation methods of the present invention are not therefore limited to the following examples.

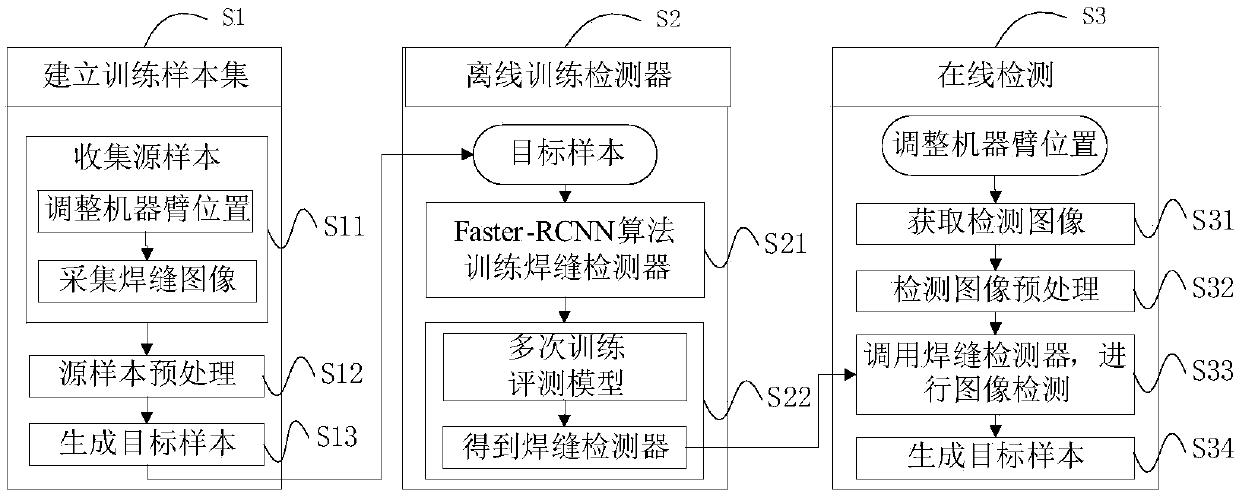

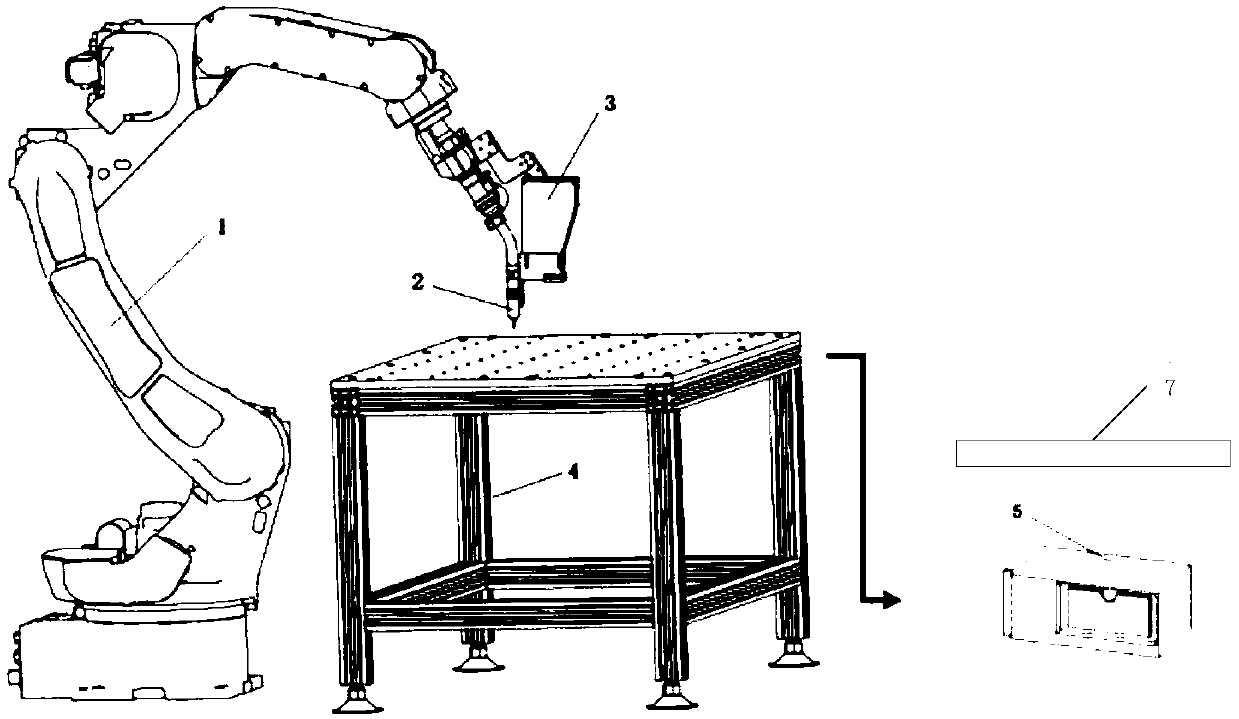

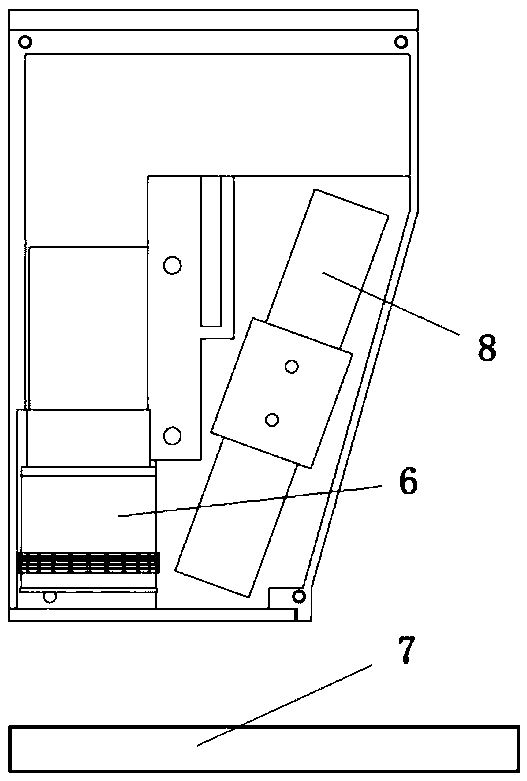

[0018] A method for real-time detection of a weld target, in one embodiment, the method is based on a detection system such as figure 2 As shown, it includes a six-degree-of-freedom mechanical arm 1, a welding torch 2, a line laser sensor 3, a workbench 4, an embedded controller 5, and a workpiece 7. The workpiece 7 is placed on the workbench 4, and the line laser vision sensor 3 is installed on the welding torch 2. Above, the welding torch 2 is placed at the end of the six-degree-of-freedom mechanical arm 1, and the line laser sensor 3 and the welding torch 2 change their positions in space through the movement of the six-degree-of-freedom mechanical arm 1. The internal structure of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com