CAN bus self-checking and repairing device and method

A CAN bus, self-reset technology, applied in data reset devices, bus networks, error detection/correction, etc., can solve the problems of vehicles unable to achieve self-repair, difficult hardware self-reset of vehicles, etc., to achieve self-repair and ensure communication. effect of function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to enable those skilled in the art to further understand the features and technical contents of the present invention, the embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings and implementation methods.

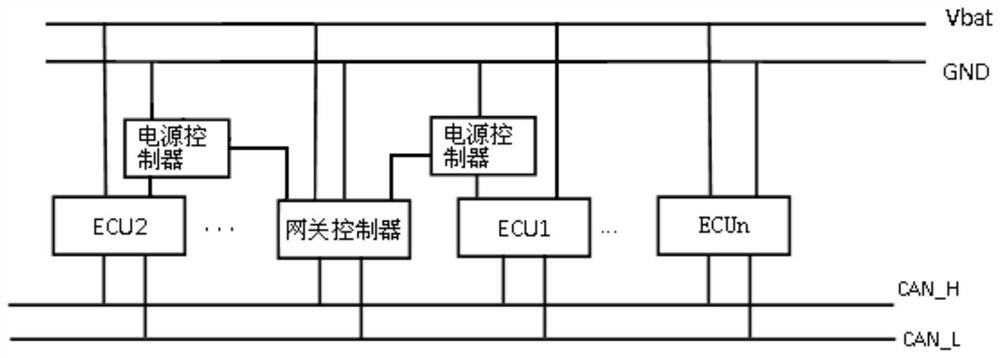

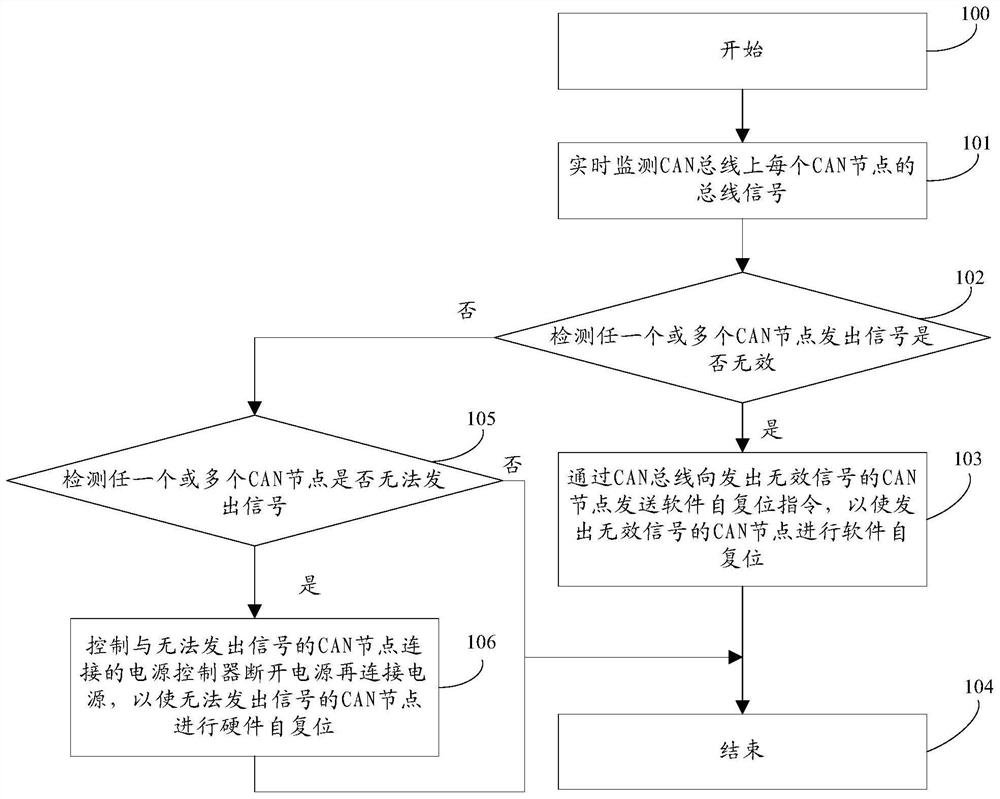

[0039] Such as figure 1 Shown is a schematic structural view of a CAN bus self-checking and repairing device in an embodiment of the present invention, the device is used for a CAN bus with at least one CAN node, and the device includes: a gateway controller and an electrical connection with the gateway controller 1. A power controller connected to the CAN nodes one by one, the power controller is used to control the on-off of the CAN node power supply; the gateway controller is located on the CAN bus and is used to monitor the bus signal of each CAN node. When one or more CAN nodes send invalid signals, send a software self-reset command to the CAN nodes that send invalid signals through the CAN...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com