Non-stirring automatic identification brewing method

An automatic identification and stirring technology, which is applied in beverage preparation devices, home appliances, applications, etc., can solve the problems that affect the convenience and ease of operation, increase the space occupied by the machine, and put it aside at will, so as to save labor costs and The effect of space occupation cost, increasing varieties and specifications, and reducing the frequency of maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

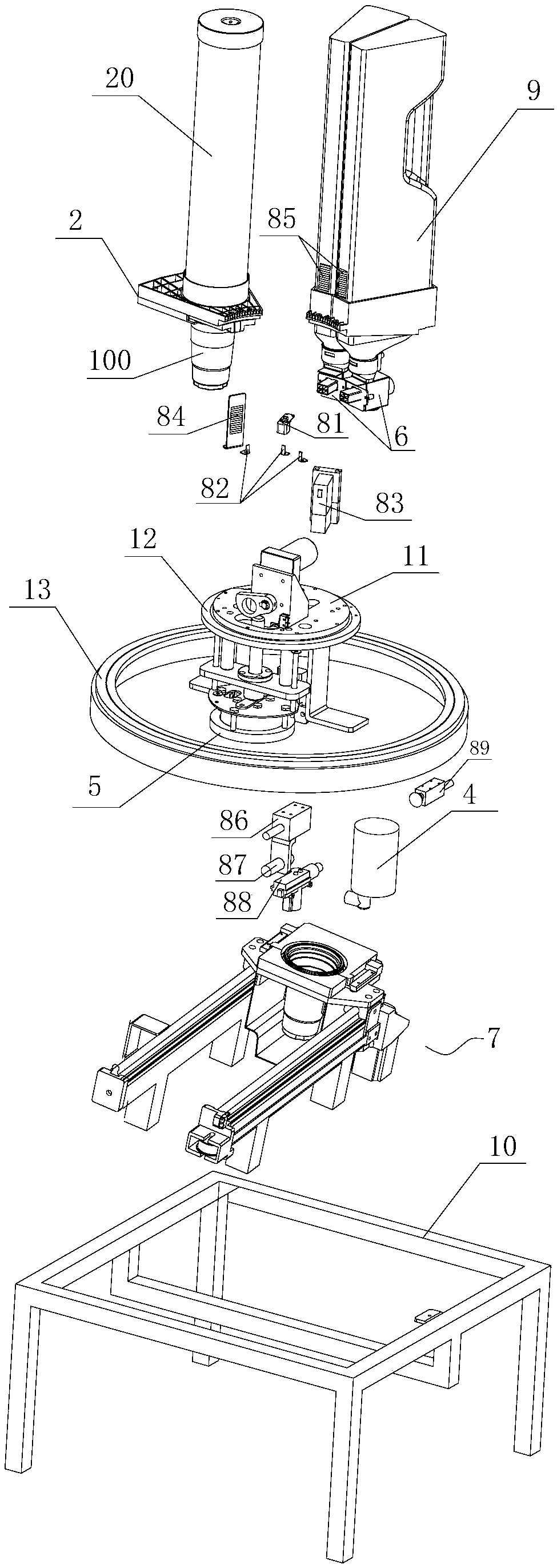

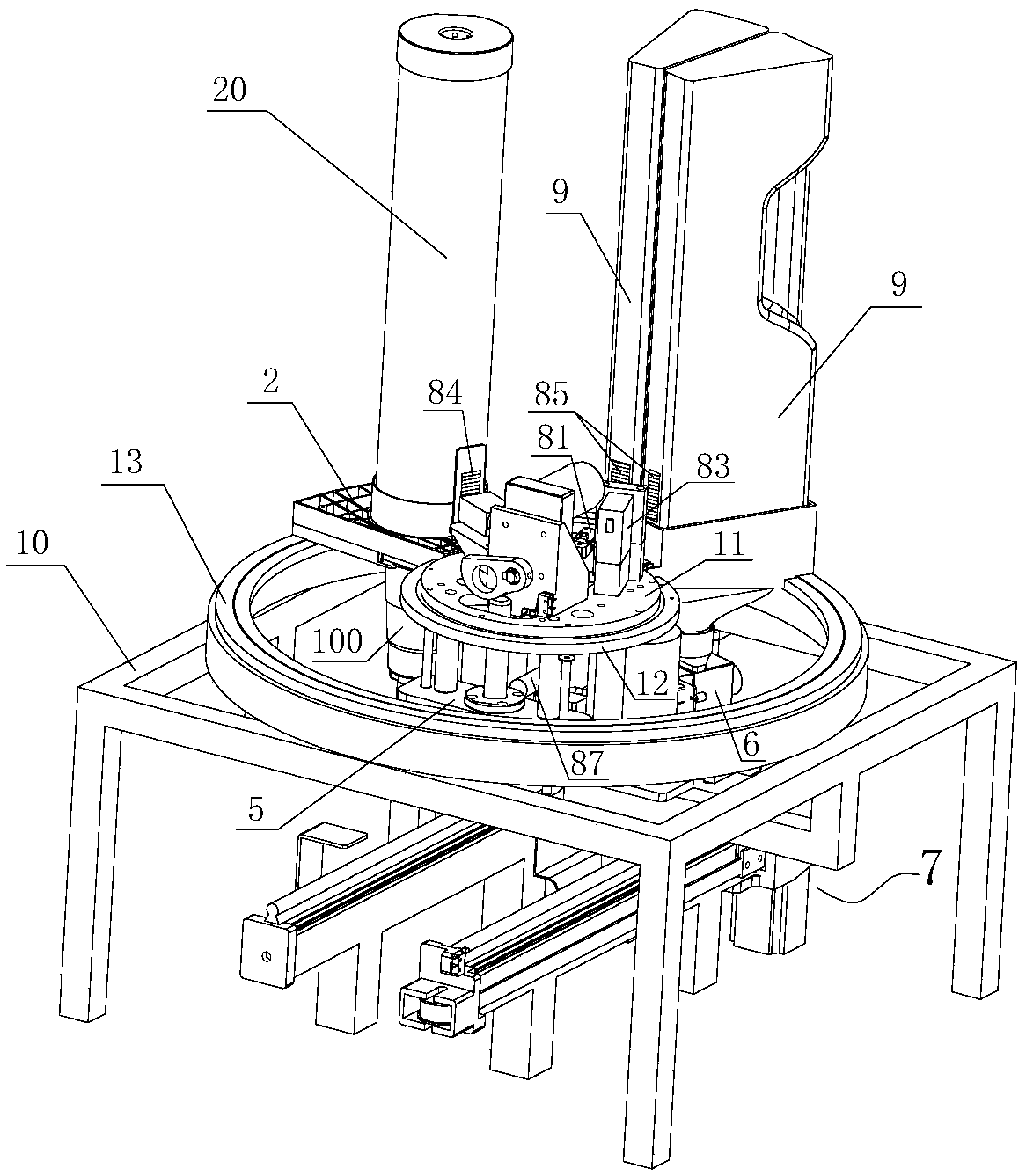

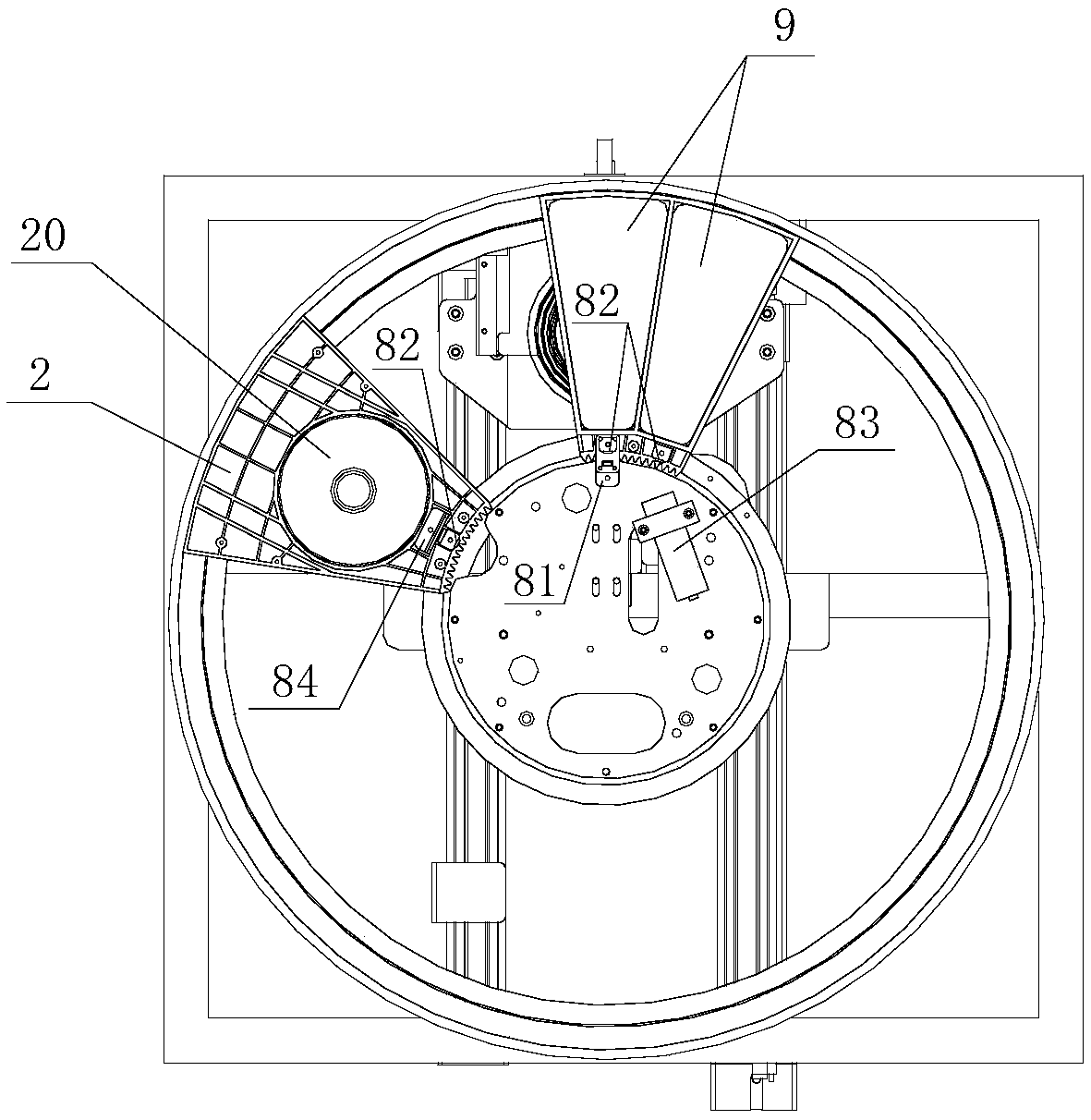

[0066] System Embodiment 1: An automatic recognition brewing machine (also called an automatic recognition brewing vending machine) provided in Embodiment 1, its structural schematic exploded diagram is as follows figure 1 As shown, the structural schematic general assembly stereogram is shown in figure 2 As shown, the simple top view of the structure is as follows image 3Shown, comprise support 10, be installed on the rotating device on the support 10 such as the turntable, and be installed on the turntable more than one cup drop mechanism and more than one material blanking mechanism (that is, the turntable is equivalent to installing the drop cup mechanism in the present embodiment) Falling cup support and the blanking support for installing the blanking mechanism), and the cup-moving and cup-out mechanism 7 located at / below the turntable; In this embodiment specifically as figure 1 , 2 , 3, including 1 cup dropping mechanism and 2 blanking mechanisms, of course, it ca...

Embodiment 2

[0085] System Embodiment 2: The structure is basically the same as that of System Embodiment 1, and the similarities will not be repeated here. The difference is:

[0086] The cup dropping mechanism provided in this embodiment includes a cup dropping device 2 and a cup storage device 20 set on the cup dropping device 2. In some preferred embodiments, the cup dropping device is installed on the turntable and the structure of the cup dropping push rod mechanism Schematic assembly diagram as Figure 16 As shown, the schematic diagram of the structural relationship between the cup drop slider, the first elastic member and the cup drop base in the cup drop device is shown in Figure 17 As shown, the schematic perspective view of the structure of the cup drop slider in the cup drop device is shown in Figure 18 with 19 As shown, the structural relationship between the cup drop base, the cup drop slider and the two pressure plates in the cup drop device is as follows: Figure 20 s...

Embodiment 3

[0104] The embodiment of this method provides a non-stirring type automatic identification brewing method (also called a non-stirring type automatic identification brewing vending method), the brewing machine (also called a brewing vending machine) system used in it includes: A processor, and a cup drop mechanism, a material drop mechanism, a water supply mechanism, a cup sealing mechanism, and a cup removal mechanism connected to the processor, the cup removal mechanism includes a displacement device; the method includes the following initialization steps and brewing step:

[0105] The initialization steps include:

[0106] A0) Steps of installing (replacing) the cup holder in the cup drop mechanism and / or installing (replacing) the replaceable powder box in the drop mechanism, and updating the corresponding identification code; specifically include:

[0107] Install / replace the cup holder for storing cups in the cup drop mechanism on the turntable, and update the correspond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com