Brazing filler metal grinding facility and system

A technology of brazing material and equipment, applied in the field of brazing material grinding equipment and its system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

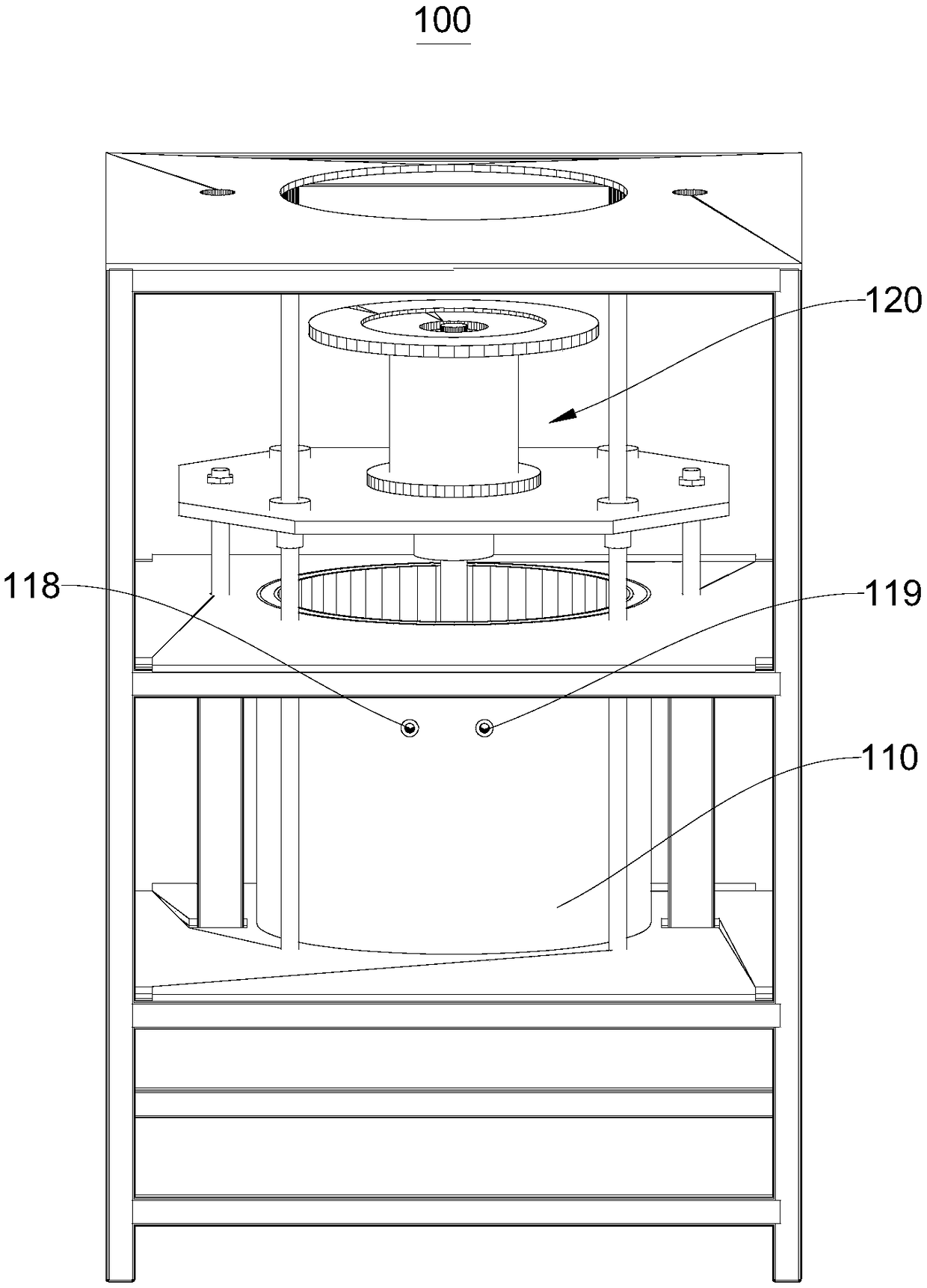

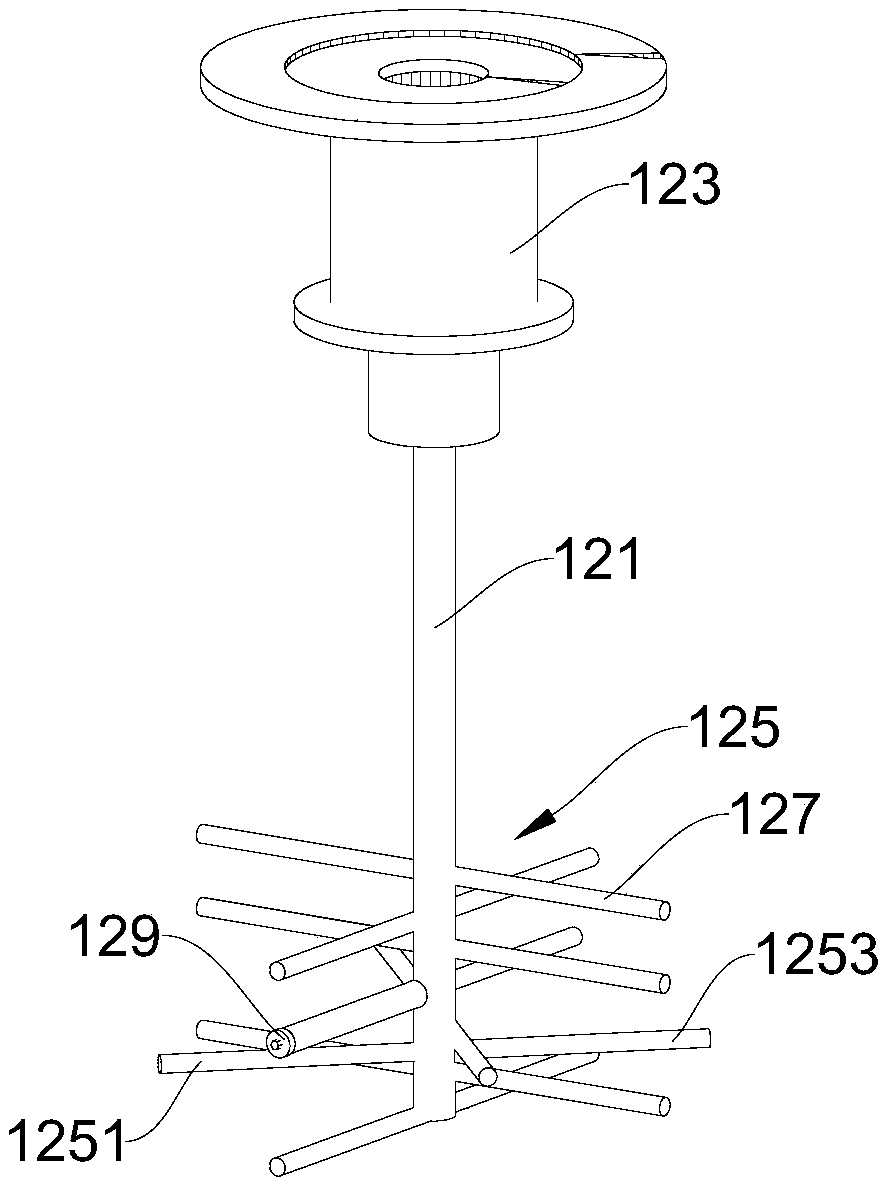

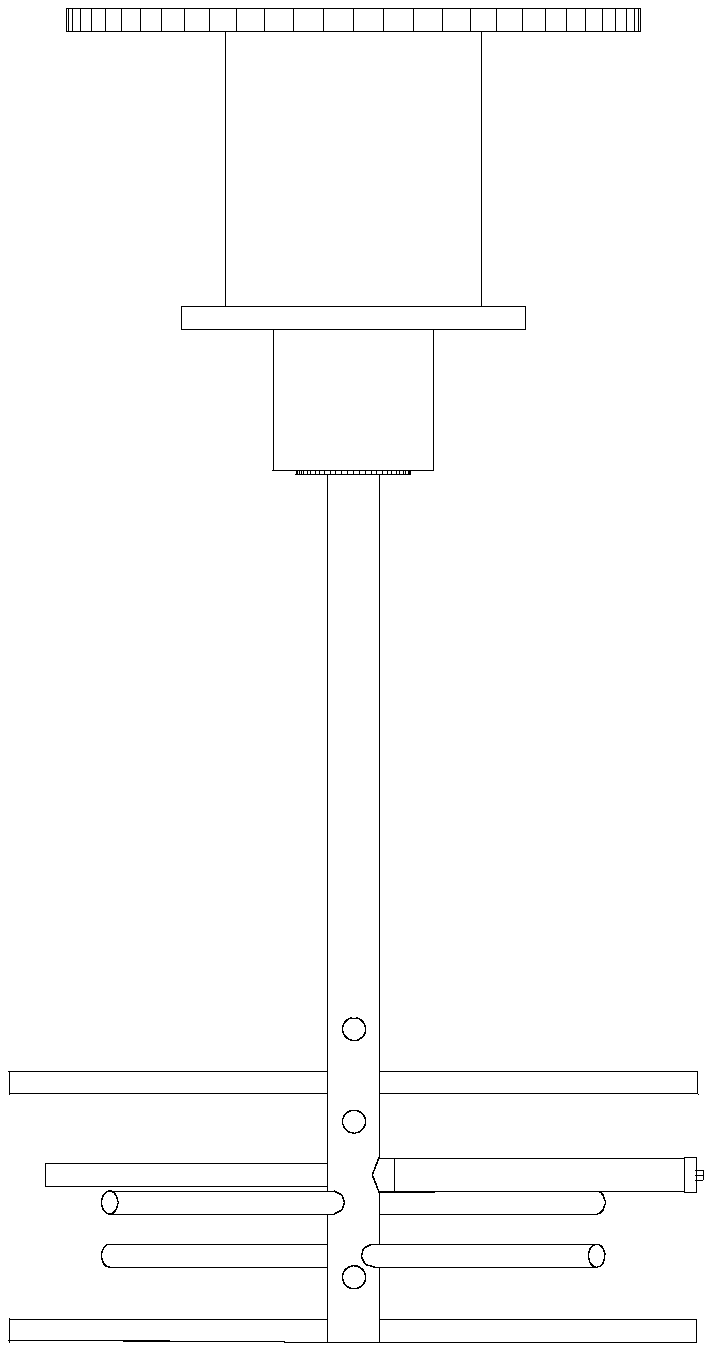

[0038] Please refer to figure 1 , figure 2 and image 3 , the present embodiment provides a solder grinding device 100, including a grinding barrel 110 and a grinding assembly 120, the grinding assembly 120 includes a stirring rod 121, and one end of the stirring rod 121 extends into the inside of the grinding barrel 110 through the opening of the grinding barrel 110, for The solder in the grinding bucket 110 is stirred and ground.

[0039] Specifically, the grinding assembly 120 includes a motor base 123 and a stirring rod 121. A motor (not shown) is arranged in the motor base 123. One end of the stirring rod 121 is connected to the bearing of the motor, and the other end extends into the grinding chamber through the opening of the grinding bucket 110. Inside the barrel 110, the motor drives the stirring rod 121 to rotate. In this embodiment, the motor is a general device in the technical field, which is not limited in the present invention.

[0040] For stirring effect,...

Embodiment 2

[0048] Please refer to image 3 and Figure 5 , the present embodiment also provides a solder grinding system 200 based on the solder grinding equipment 100, including a frame body 210 and a solder grinding device 100, the frame body 210 is arranged on the top of the grinding barrel 110, and the grinding assembly 120 is erected on the frame body 210. The frame body 210 can stabilize the grinding assembly 120 , and the frame body 210 in this embodiment can be stretched and retracted to change the height of the grinding assembly 120 to stir and grind solders with different solvents.

[0049] For simplified representation, please refer to the corresponding content in Embodiment 1 for those not mentioned in this embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com