Improved device for old-fashioned punching machine

A punching machine, an old-fashioned technology, applied in the field of improvement devices, can solve the problems of low utilization rate of safety materials, low utilization rate of plates, neglected cost, etc., and achieve the effect of saving labor intensity, convenient installation and transformation, and low manufacturing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

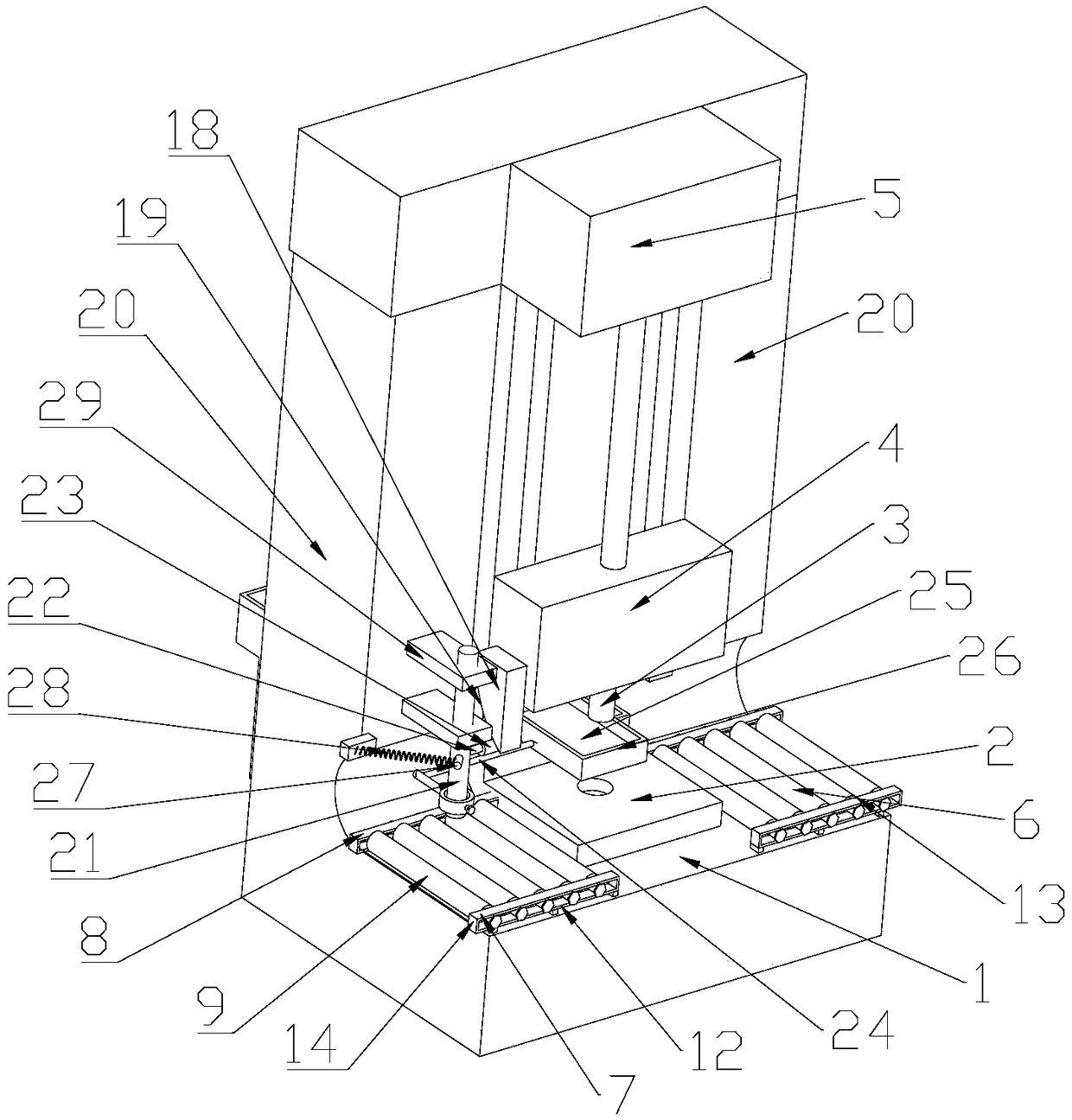

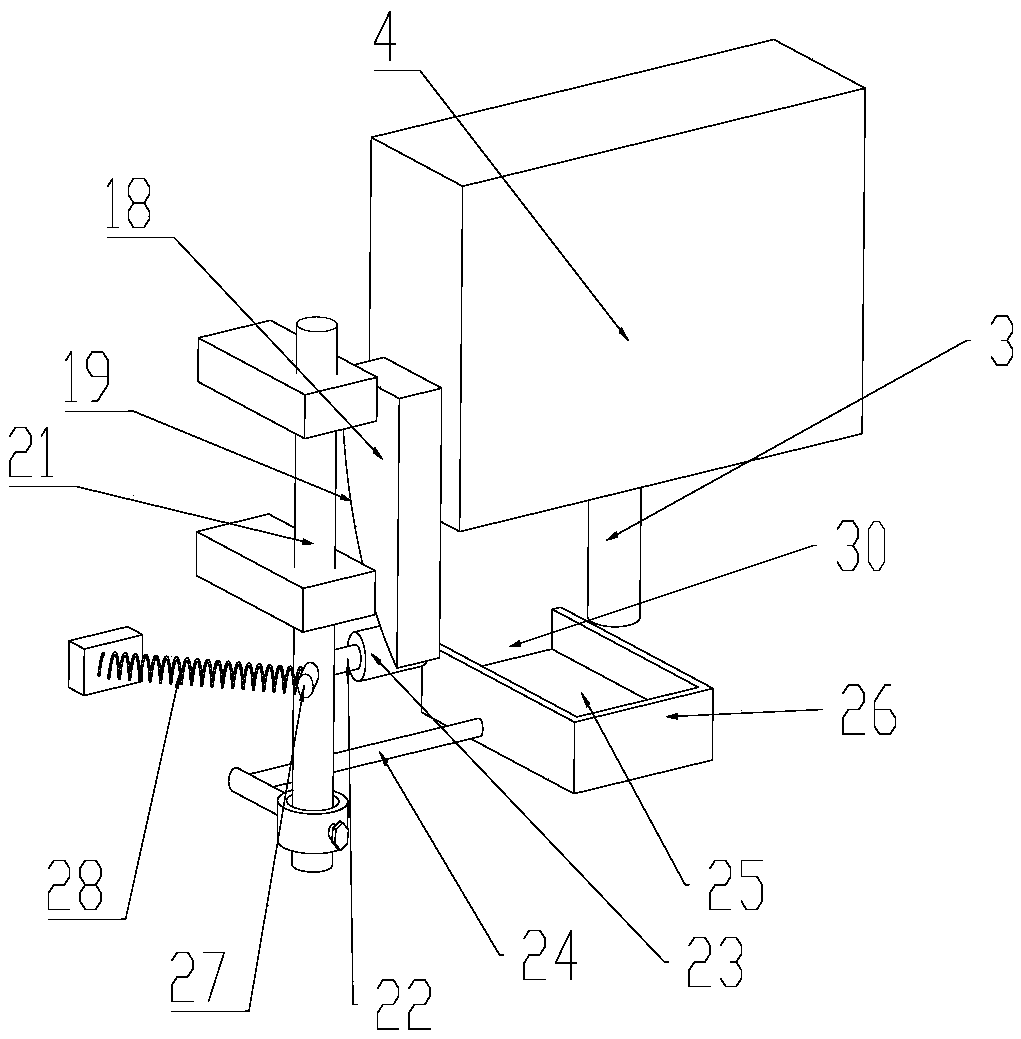

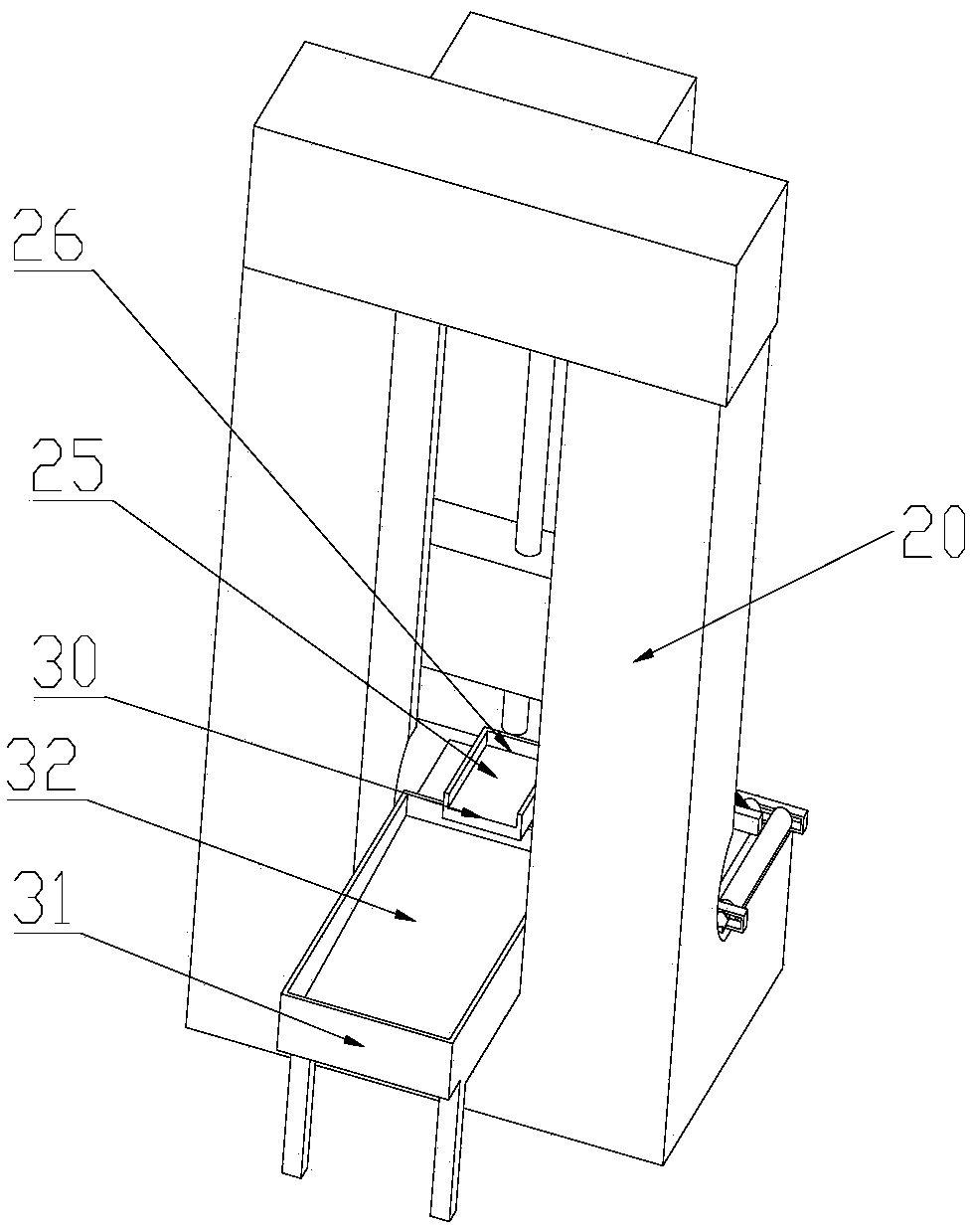

[0018] The present invention will be further described now in conjunction with accompanying drawing.

[0019] like Figure 1-4 As shown, an improved device used on an old-fashioned punching machine, the old-fashioned punching machine includes a console 1, a lower mold 2 is arranged on the console 1, an upper mold 3 is arranged above the lower mold 2, and the upper mold 3 is installed on a slide On the block 4, the slide block 4 is driven downward by the driving device 5 for stamping movement, and the operation table 1 on both sides of the lower mold 2 is respectively provided with a conveying device 6, and the conveying device 6 includes a front bracket 7, a rear bracket 8 and Some rollers 9, roller 9 include rotating cylinder 10 and fixed shaft 11, rotating cylinder 10 is installed on the fixed shaft 11 by some bearings, and the two ends of fixed shaft 11 are respectively installed on the front bracket 7 and the rear bracket 8, with The gap distance between the rollers 9 in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com