A laser shock pressure welding automatic clamping and picking device and method thereof

An automatic clamping and laser shock technology, applied in laser welding equipment, welding equipment, non-electric welding equipment, etc., can solve the problems of low automation, cumbersome operation, undesigned welding parts removal device, etc., and achieve high automation and precision High, improve the effect of welding quality and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

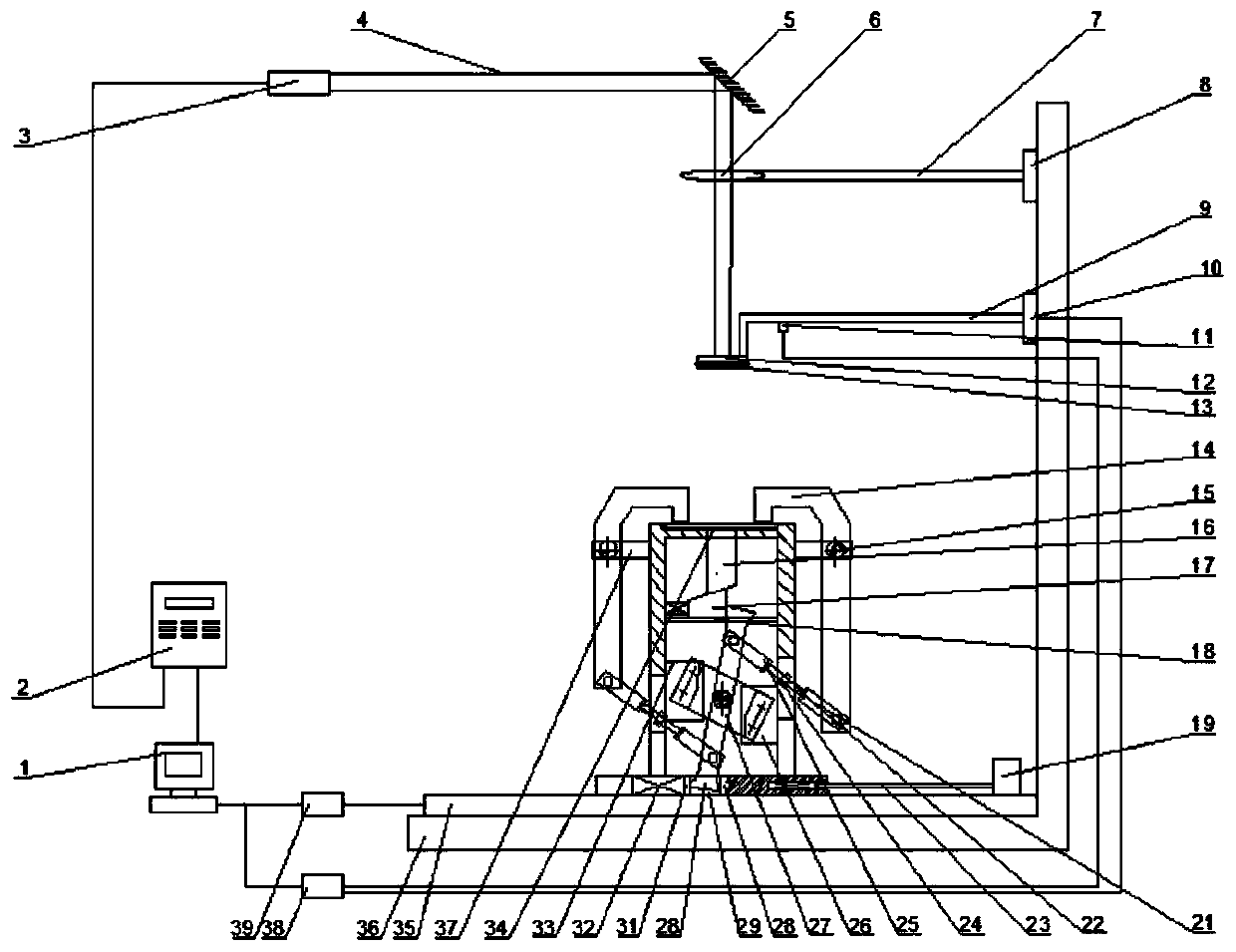

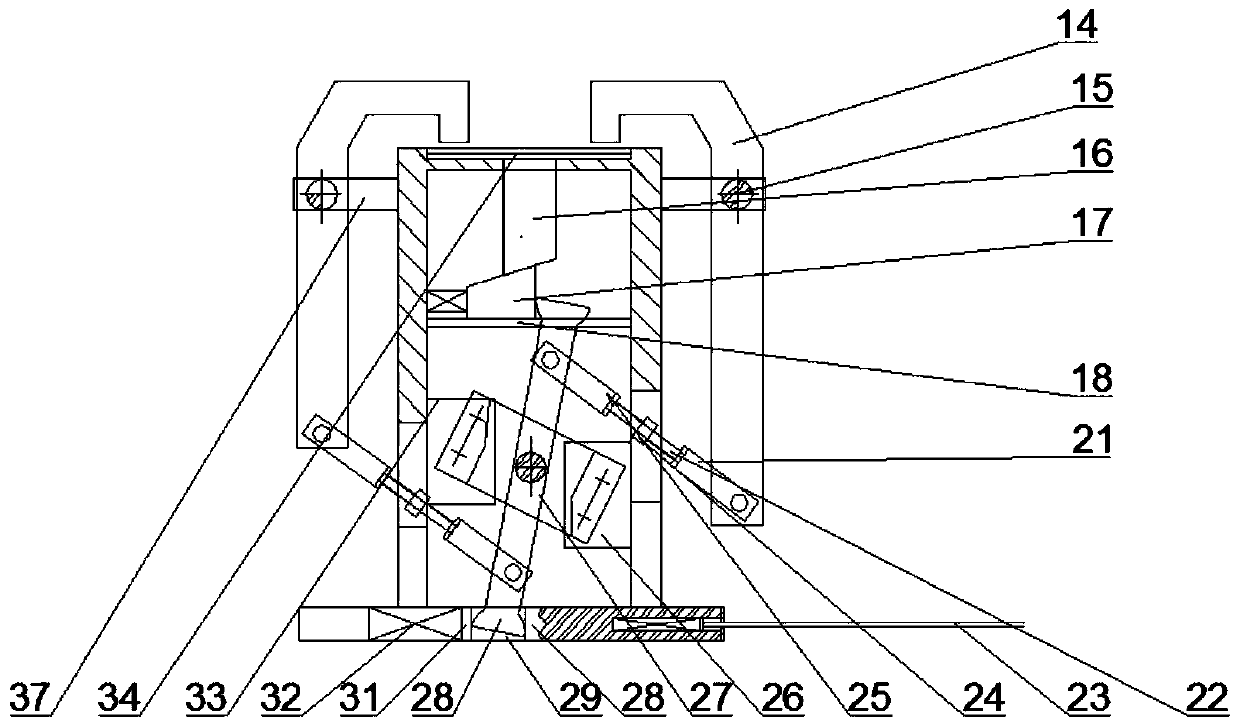

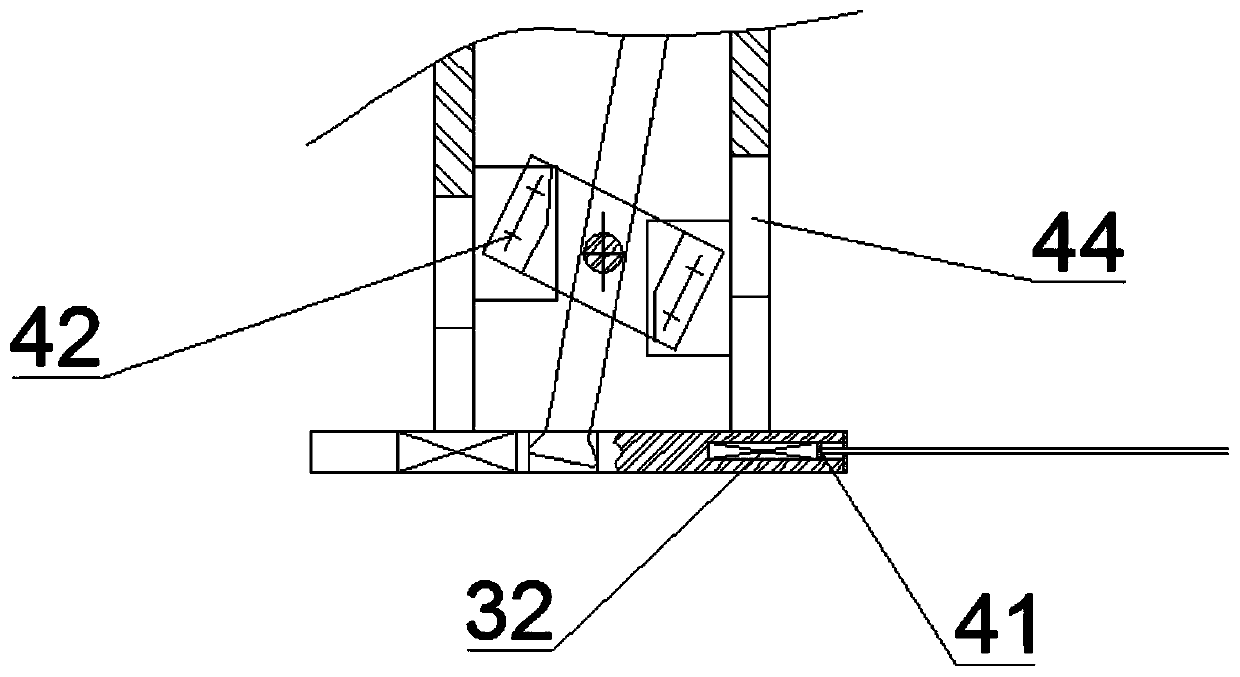

[0036] Such as figure 1 Shown is an embodiment of a laser shock pressure welding automatic clamping and picking device and its method according to the present invention, the device includes a laser emitting system, an automatic clamping system, a welding system, and a control system.

[0037] Such as figure 1 As shown, the laser emitting system includes a pulsed laser 3, a laser beam 4, a mirror 5, a focusing lens 6, a focusing lens bracket 8, and a focusing lens position adjustment device 8; the laser controller 2 is connected to the computer 1 and the pulsed laser respectively 3 are connected by electrical signals, the focus lens 6 is connected to the focus lens position adjustment device 8 through the focus lens bracket 7, and the focus lens position adjustment device 8 is installed on the side plate of the L-shaped base 33; the reflector 5 is located on the focus lens 6 above, the pulsed laser 3 emits a laser beam 4 that is focused on the absorbing layer 39 through the mirr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com