Clutch connecting disc machining equipment

A technology for processing equipment and connecting discs, which is applied in metal processing equipment, solid separation, manufacturing tools, etc., can solve the problems affecting the overall performance and life of the brake system, cracking of the clutch connecting disc, and large friction, and achieves good processing results. Long sliding time and uniform processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

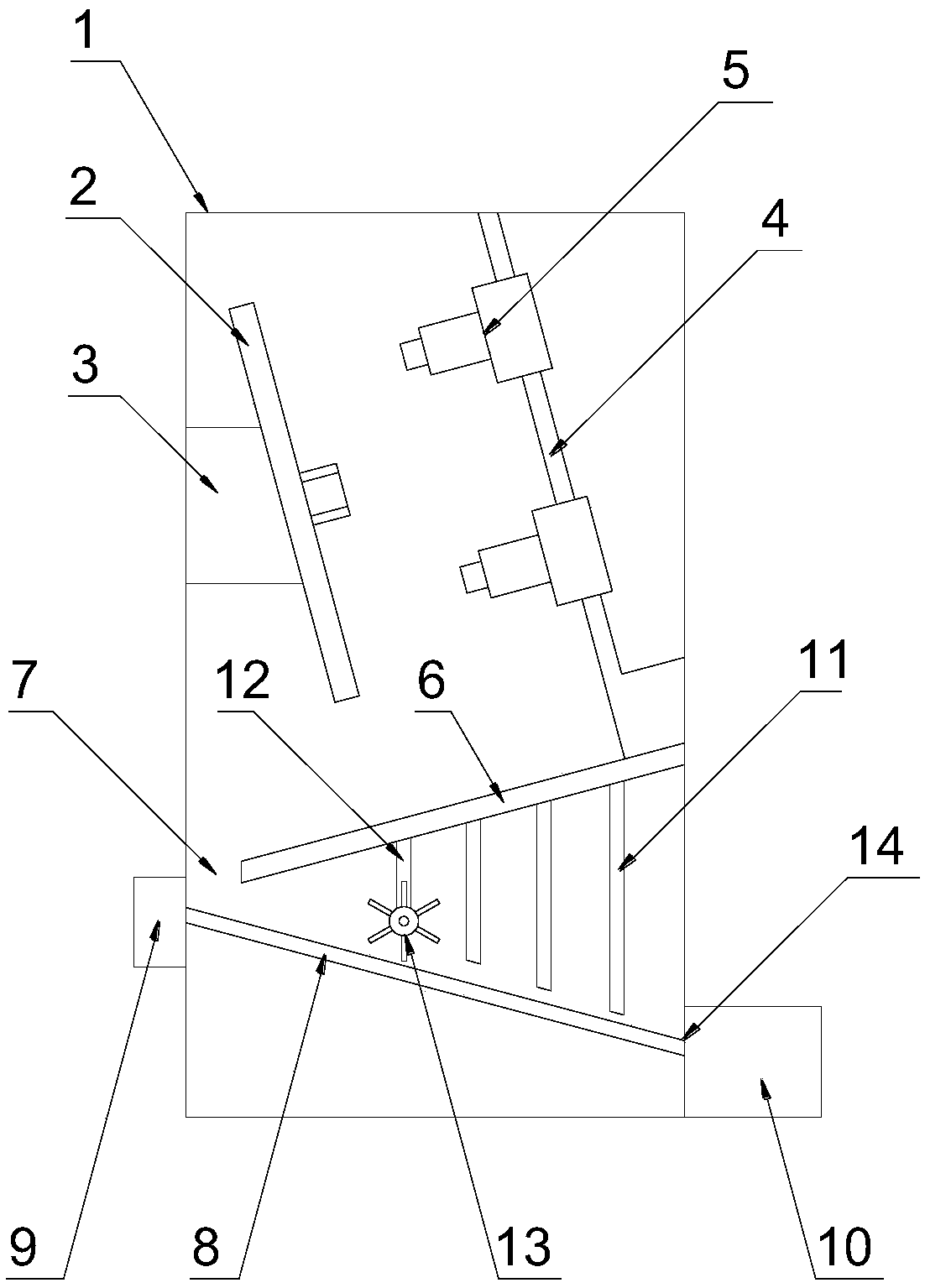

[0020] Such as figure 1 as shown, figure 1 It is a structural schematic diagram of a clutch connecting disc processing equipment proposed by the present invention.

[0021] refer to figure 1 , a clutch connection plate processing equipment proposed by the present invention, including a housing 1, a turntable 2, a mounting frame 3, a frame 4, a shot blaster 5, a guide plate 6, a vibrating screen 8, a vibrating motor 9, and a limit plate 11 and recycling bins 10;

[0022] The mounting frame 3 and the frame 4 are arranged on the upper part of the housing; the turntable 2 is arranged on the mounting frame 3, an acute angle is formed between the turntable 2 and the vertical surface, and the middle part of the turntable 2 is provided with a mechanical claw for clamping the connecting disk; The mounting frame 3 is provided with a driving device that drives the turntable 2 to rotate and drives the mechanical jaws to open and close; the shot blaster 5 is arranged on the frame 4, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com