Processing and repairing drilling platform for stamping plastic products

A technology for drilling platforms and plastic products, applied in metal processing and other directions, can solve the problems that the height of the inspection platform cannot be changed, and the use of different maintenance personnel is not convenient, and achieves the effect of simple structure and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solution of the present patent will be described in further detail below in conjunction with specific embodiments.

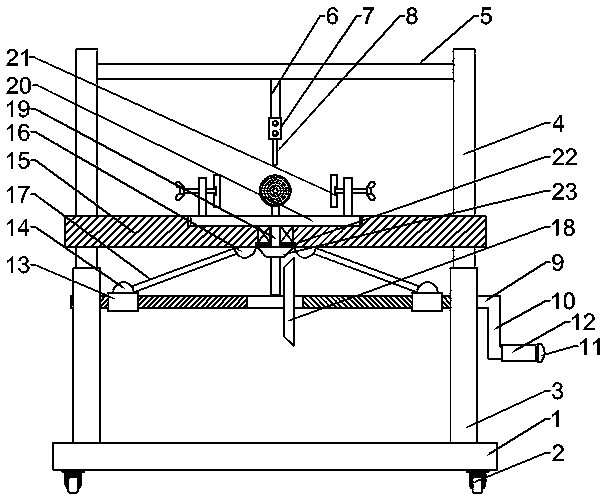

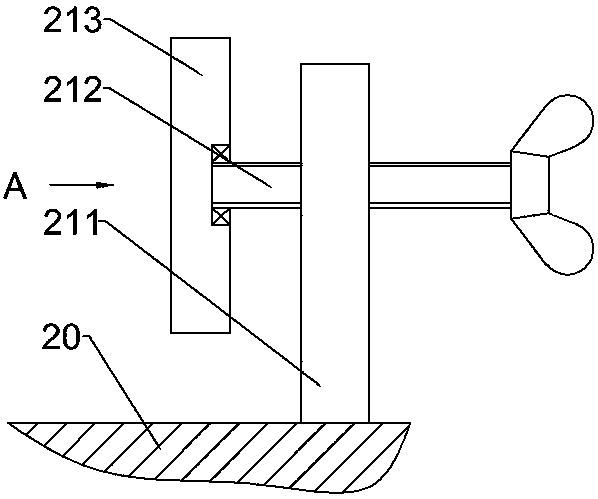

[0022] see figure 1 , a processing and repairing drilling platform for stamping plastic products, comprising a fixed base 1, a fixed column 3 is fixedly connected to the left and right symmetrically above the fixed base 1, and a guide column 4 is slidably connected above the fixed column 3. The guide column 4. A horizontal beam 5 is fixedly connected at the top, a longitudinal connecting rod 6 is fixedly connected at the bottom of the middle of the horizontal beam 5, a drill bit connecting seat 7 is fixedly connected at the bottom of the longitudinal connecting rod 6, and a drill bit 8 is fixedly connected under the drill bit connecting seat 7;

[0023] A screw 9 is rotatably connected to the top of the fixed support 3, a handle 10 is fixedly connected to the outer side of the screw 9, a rotating sleeve 12 is rotatably connected to the outer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com