Manufacturing method of lamellar anisotropic rock similar material

A technology with similar materials and production methods, applied in the field of rock exploration, can solve the problems of high acquisition cost of anisotropic rock mass, prone to geological disasters, weak mechanics, etc., so as to reduce acquisition difficulty and acquisition cost, reduce acquisition difficulty and make simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A method for manufacturing similar materials of layered heterogeneous rock mass, comprising the following steps:

[0023] (1) Two kinds of cement with labels of 325 and 425 are used, and each cement is mixed with river sand and water according to the mass ratio of cement: river sand: water = 0.8: 1.8: 0.30 to make 325 cement respectively Two kinds of cement mortar materials with 425 cement;

[0024] (2) The 325 cement mortar material and the 425 cement mortar material are evenly poured into two layers in the mold along the vertical direction, and the order from top to bottom is 325 cement mortar material and 425 cement mortar material, and put them into a 35°C temperature and humidity curing box Demoulding after 40 hours;

[0025] (3) Put the model in an incubator at 18°C for 25 days to form.

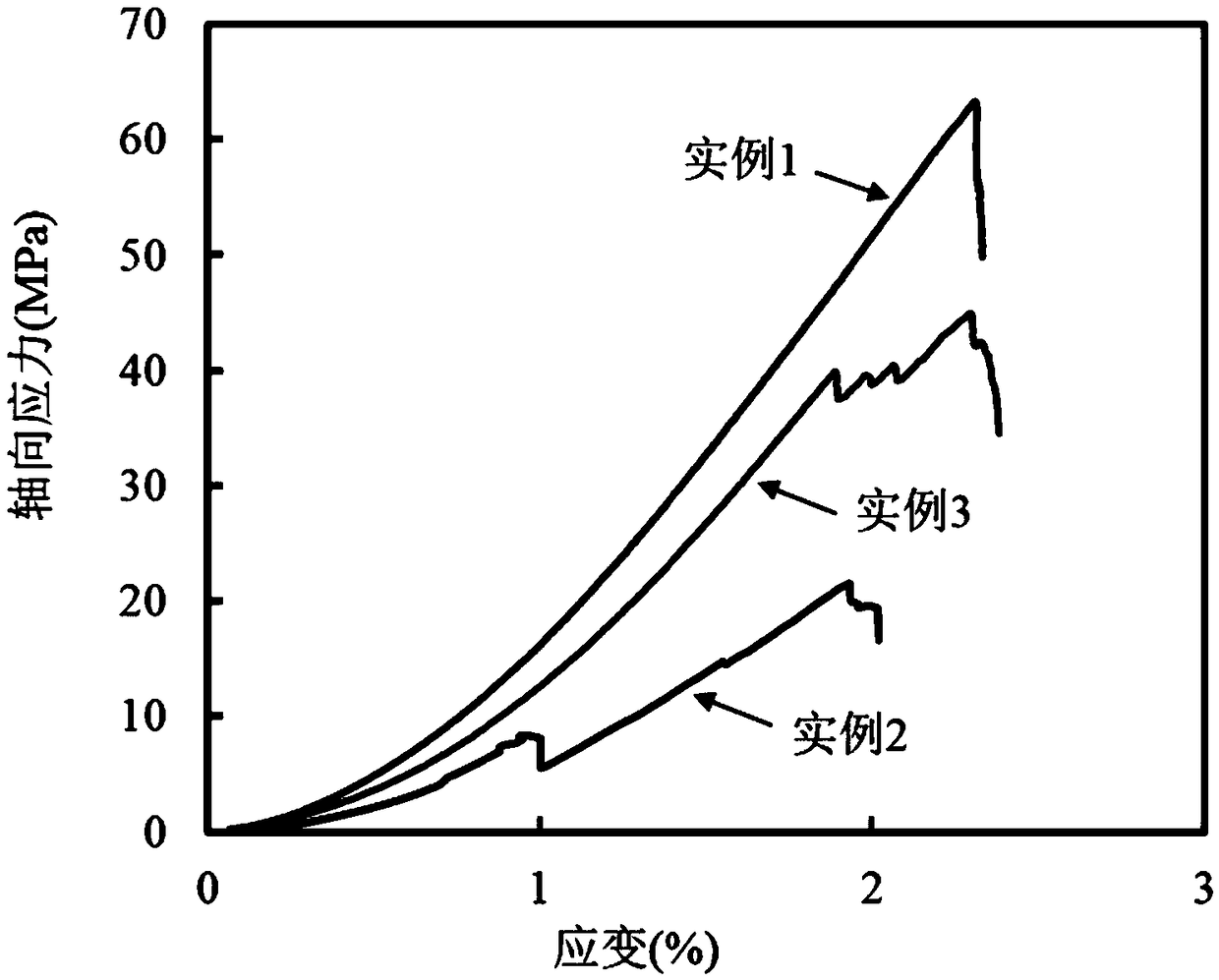

[0026] The model of similar materials of layered heterogeneous rock mass prepared by the above steps is cut perpendicular to the layer into Cylindrical specimens were subje...

Embodiment 2

[0029] A method for manufacturing similar materials of layered heterogeneous rock mass, comprising the following steps:

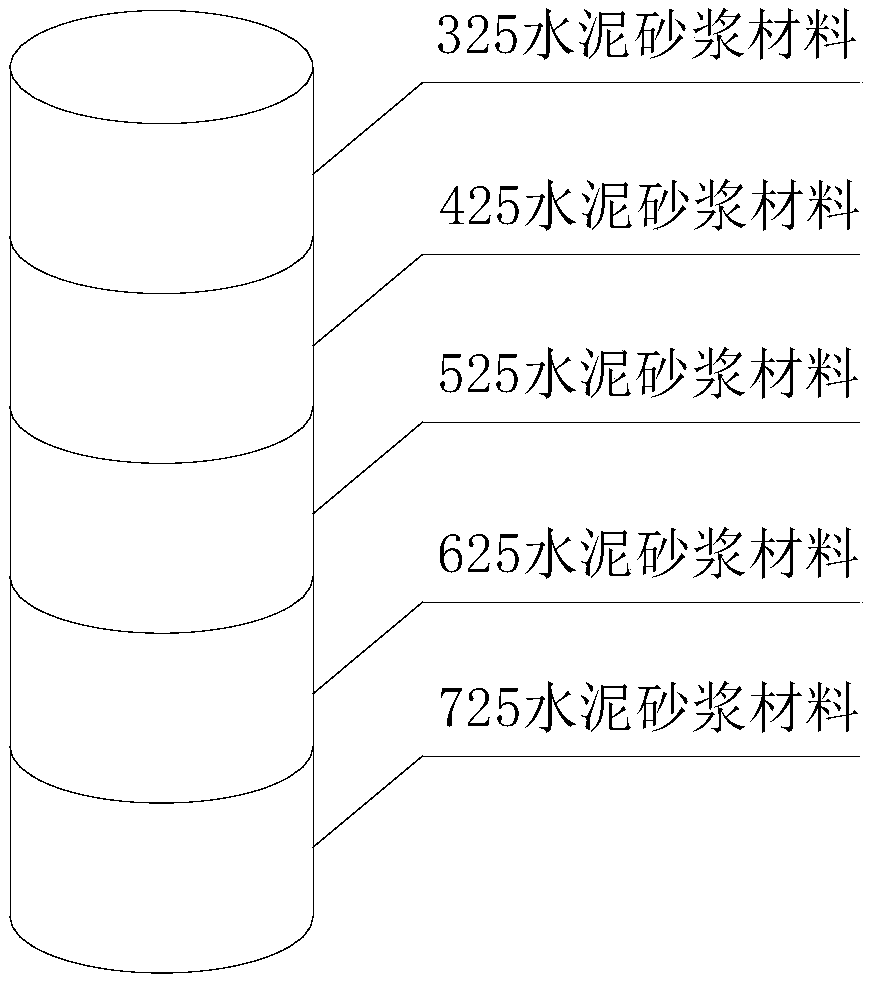

[0030] (1) adopt five kinds of cement that label is 325,425,525,625 and 725, each kind of cement is cement according to mass ratio: river sand: the ratio of water=1:2:0.35 mixes with river sand and water, Make five kinds of cement mortar materials containing 325 cement, 425 cement, 525 cement, 625 cement and 725 cement respectively;

[0031] (2) 325 cement mortar material, 425 cement mortar material, 525 cement mortar material, 625 cement mortar material and 725 cement mortar material are evenly poured into five layers in the mold along the vertical direction, and the order from top to bottom is 325 cement mortar Materials, 425 cement mortar materials, 525 cement mortar materials, 625 cement mortar materials and 725 cement mortar materials, put them in a temperature and humidity curing box at 38°C for 48 hours before demoulding;

[0032] (3) Put the model ...

Embodiment 3

[0035] A method for manufacturing similar materials of layered heterogeneous rock mass, comprising the following steps:

[0036] (1) Adopting three kinds of cements whose labels are 325, 425 and 825, each cement is mixed with river sand and water according to the mass ratio of cement: river sand: water = 1.2: 2.2: 0.4, respectively made into Three cement mortar materials of 325 cement, 425 cement and 825 cement;

[0037] (2) The 325 cement mortar material, 425 cement mortar material and 825 cement mortar material are evenly poured into three layers in the mold along the vertical direction, and the order from top to bottom is 325 cement mortar material, 425 cement mortar material and 825 cement mortar material Materials, placed in a 45°C temperature and humidity curing box for 60 hours before demoulding;

[0038] (3) Put the model in an incubator at 25°C for 35 days to form.

[0039] The model of similar materials of layered heterogeneous rock mass prepared by the above steps...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com