Automatic release agent spraying device and method for full-automatic magnetic material hydraulic machine

A magnetic material and release agent technology, applied in ceramic molding machines, inductor/transformer/magnet manufacturing, electrical components, etc., can solve problems such as low efficiency, uneven application, poor safety, etc., to achieve uniform application and improve safety , low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

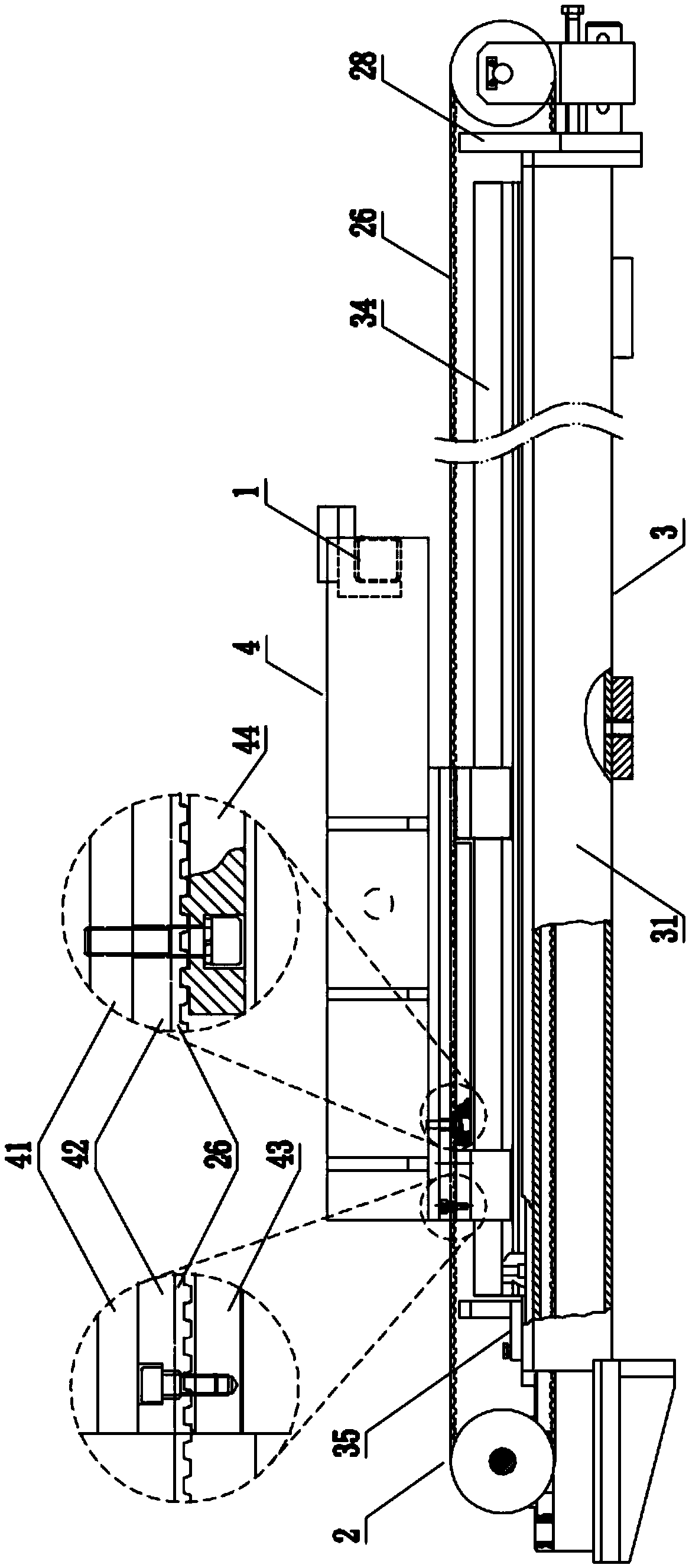

[0043] A fully automatic magnetic material hydraulic press automatic spray release agent device, such as figure 1 , 2As shown, it includes a belt conveying device 2, a guide rail device 3, a walking frame device 4 and some release agent nozzles 1, and the belt conveying device 2 and the guide rail device 3 are all installed on a hydraulic press; the belt conveying device 2 Including two belts 26 arranged in parallel, the two belts 26 are respectively located on the left and right sides of the mold cavity on the die surface of the hydraulic press, the guide rail device 3 is respectively arranged below the two belts 26, and the walking frame device 4 The left and right ends are respectively fixed on the two belts 26, and the lower side of the walking frame device 4 is slidably connected with the guide rail device 3, and the sliding connection at this place can be a cooperative connection between a chute and a slide block, or The matching connection between the slide bar and the...

Embodiment 2

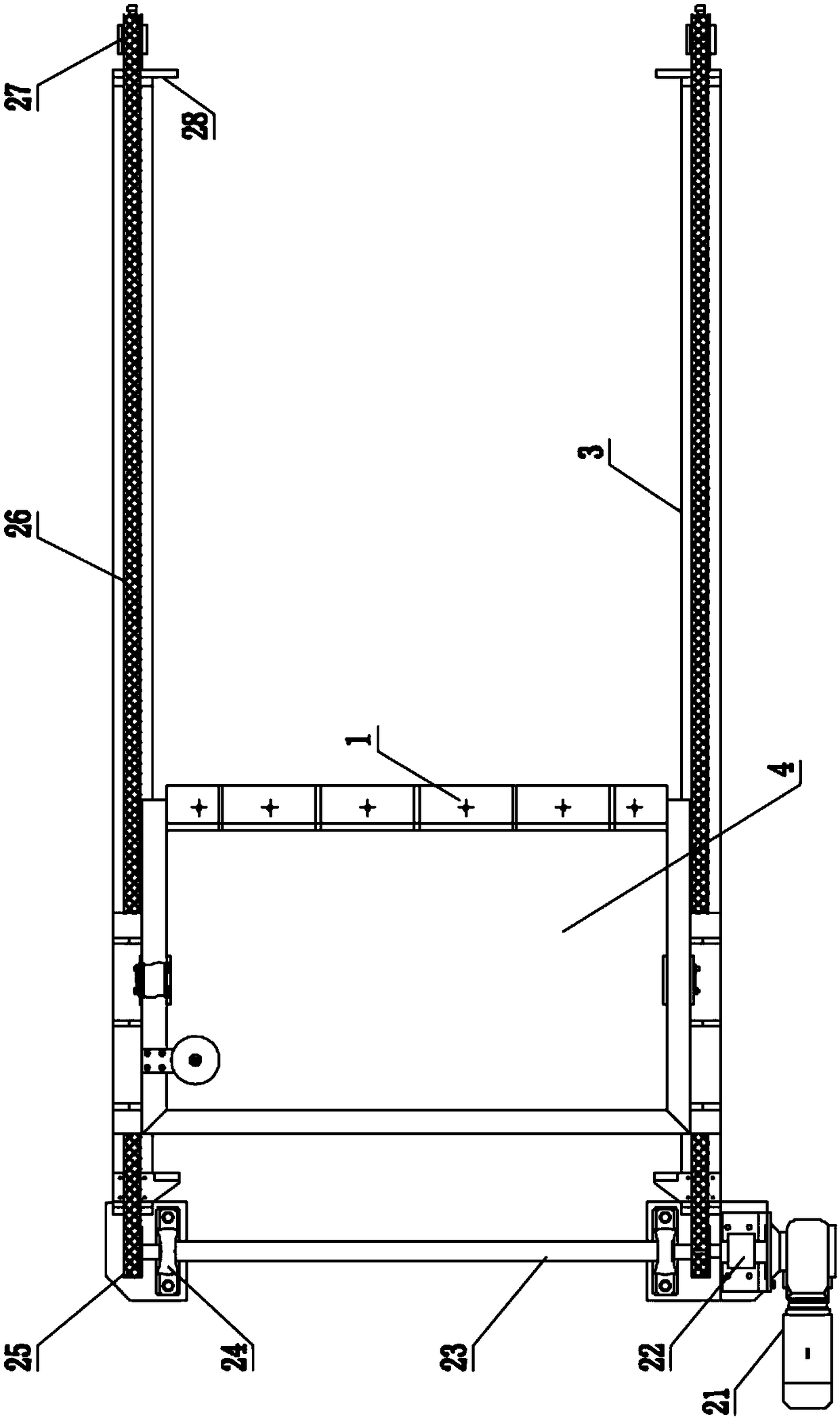

[0047] A kind of automatic release agent spraying device of a kind of automatic magnetic material hydraulic press of this embodiment, basic structure is the same as embodiment 1, and difference and improvement are, as figure 2 As shown, the belt conveyor 2 also includes a motor 21, a shaft coupling 22, a drive shaft 23, a bearing seat 24, a driving wheel 25, a driven wheel 27 and a front wheel adjustment frame 28, and the front wheel adjustment frame 28 is used To adjust the distance between the driving wheel 25 and the driven wheel 27, ensure that the belt 26 is in a tensioned state; the motor 21, shaft coupling 22, transmission shaft 23, driving wheel 25, belt 26 and driven wheel 27 are sequentially connected in transmission, And it is detachably connected, which is convenient for disassembly and maintenance. In the present embodiment, the motor 21, the shaft coupling 22, the transmission shaft 23, and the driving wheel 25 are sequentially connected by keys, and the driving ...

Embodiment 3

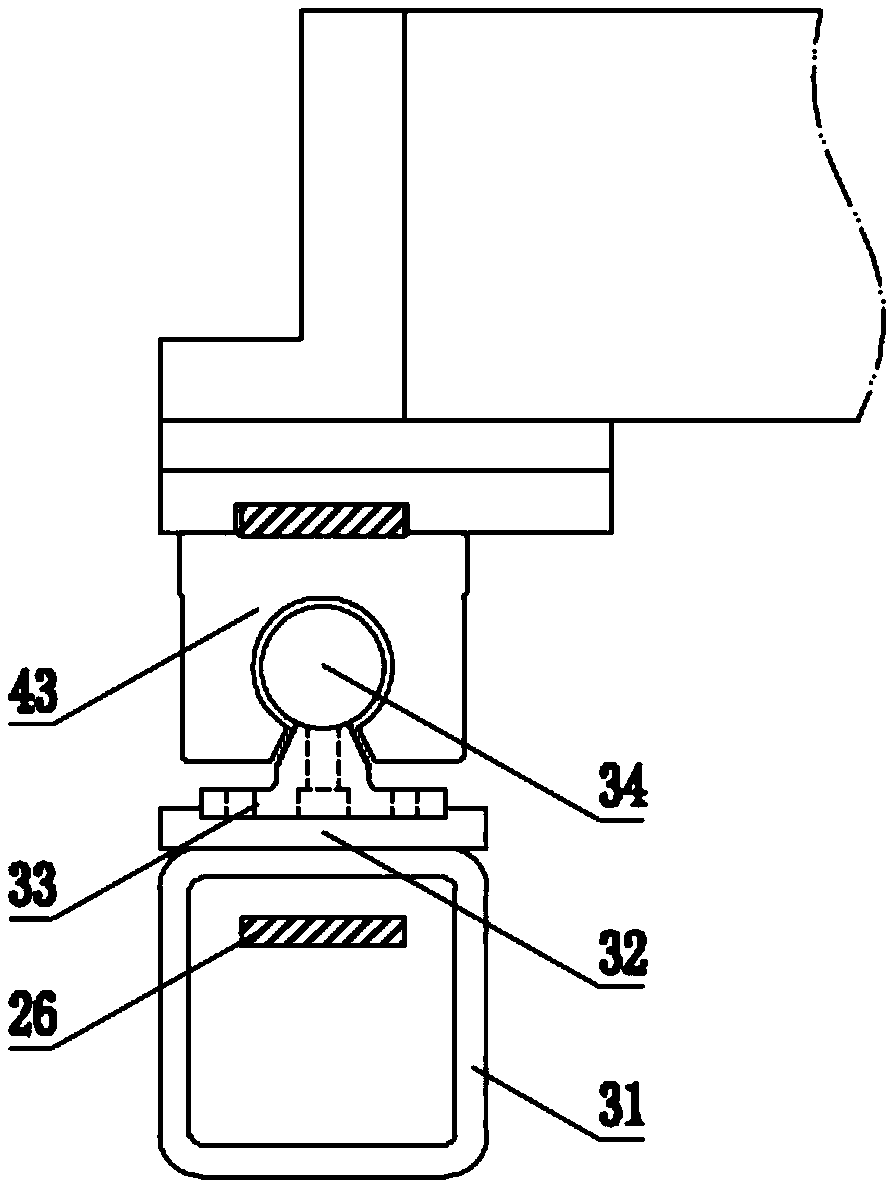

[0049] A kind of automatic releasing agent spraying device of a kind of automatic magnetic material hydraulic press of this embodiment, basic structure is the same as embodiment 1 or 2, and difference and improvement are, as figure 1 , 3 As shown, the guide rail device 3 includes a sleeper 31, a mounting plate 32, a guide rail seat 33 and a guide rail 34 fixedly connected sequentially from bottom to top, the sleeper 31 is used to support the mounting plate 32, and the mounting plate 32 is used to install the guide rail Seat 33, the guide rail 34 is installed on the guide rail seat 33; the sleeper 31 and the guide rail 34 are arranged along the length direction of the belt 26, between the sleeper 31, the mounting plate 32, the guide rail seat 33 and the guide rail 34 It can be detachably fixedly connected or welded, or integrally formed. The traveling frame device 4 is slidingly connected to the guide rail 34 , that is, the traveling frame device 4 can slide forward and backwar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com