Continuous and automatic tray collecting and dispensing mechanism of detection equipment

A technology of automatic tray and retractable mechanism, which is applied in the direction of conveyor, object stacking, and object destacking, etc. It can solve the problems of destroying good products, large demand for manual labor, and affecting detection speed, so as to reduce the operation error rate , Improve detection efficiency and reduce manual effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the purpose, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

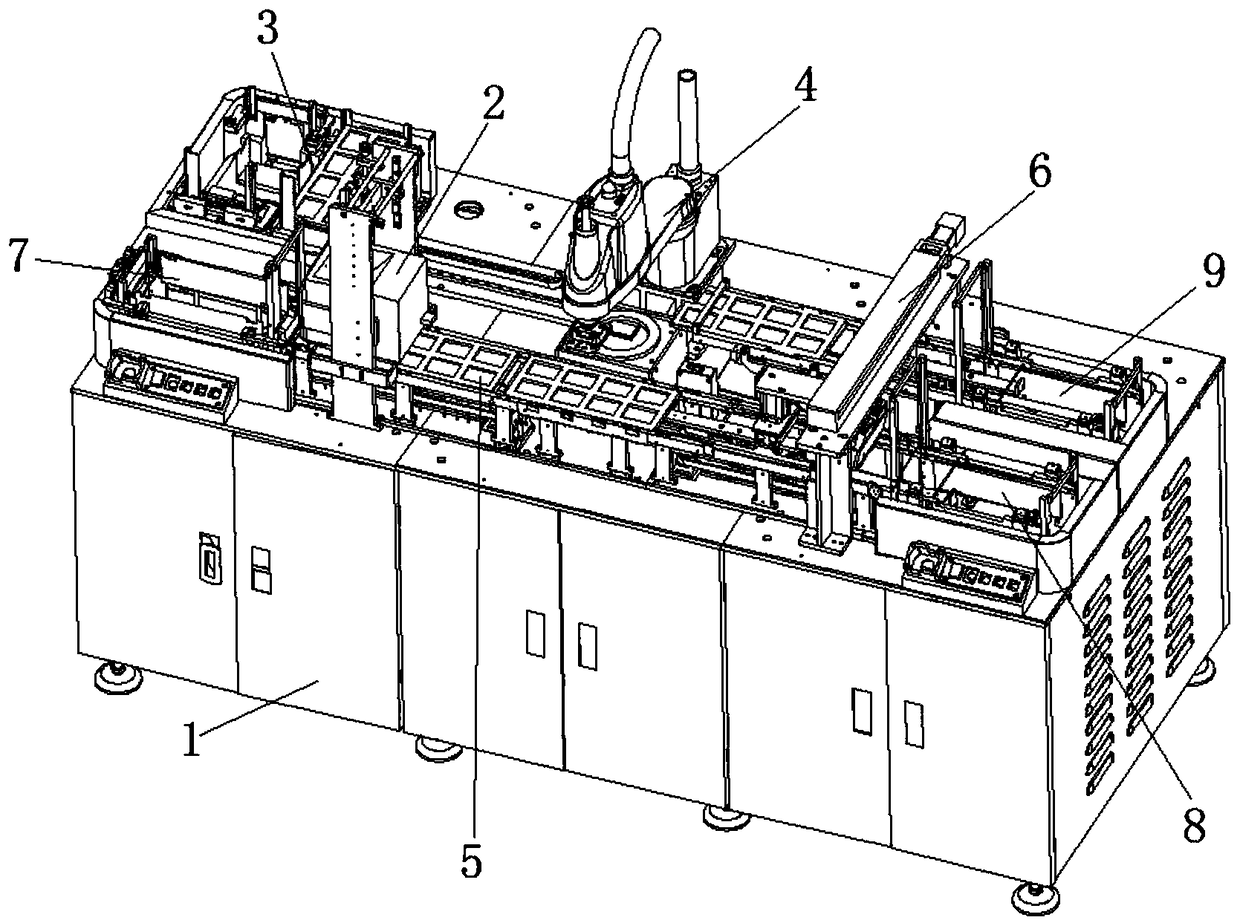

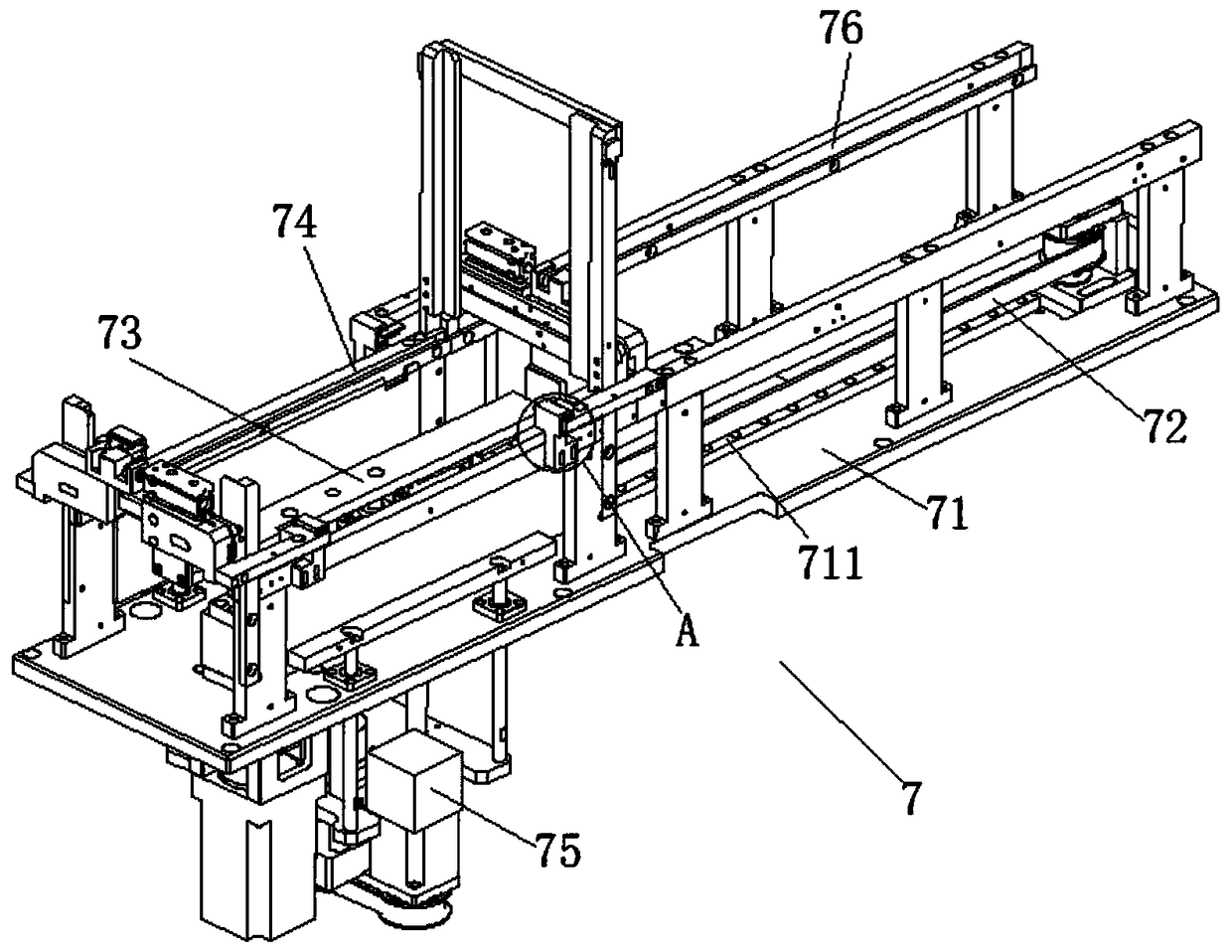

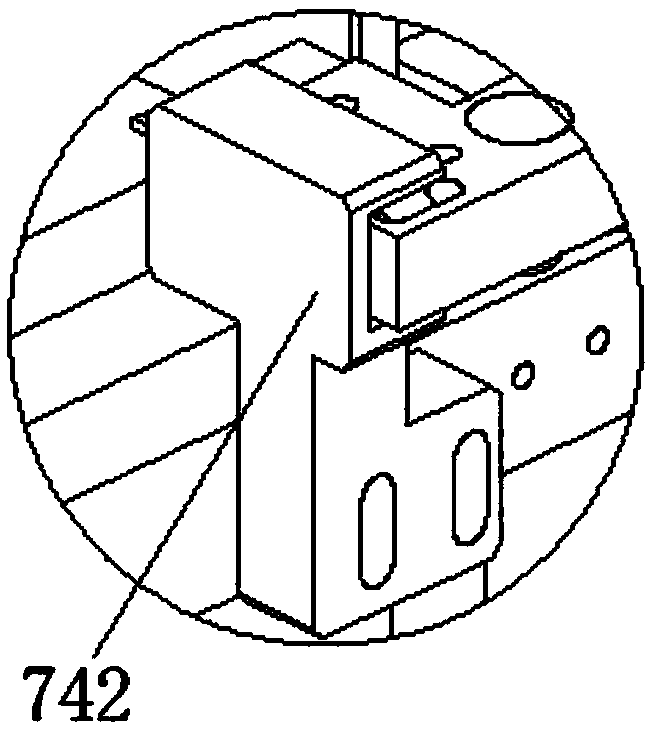

[0033] refer to Figure 1 to Figure 13, a continuous automatic tray retracting mechanism for testing equipment, the equipment includes a frame 1, a testing device 2, a defective product collection mechanism 3, a screening manipulator 4, a screening conveyor table 5, a pallet handling mechanism 6, a pallet lowering mechanism 7, a good product The collection mechanism 8 and the tray collection mechanism 9, the good product collection mechanism 8 and the tray collection mechanism 9 have the same structure; the tray lowering mechanism 7 includes a first bottom plate 71, and the first bottom plate 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com