Circulation oxygen generation equipment

An oxygen production equipment, the first technology, applied in the fields of oxygen preparation, oxygen/ozone/oxide/hydroxide, inorganic chemistry, etc., can solve the problems of bulky and large space, achieve simple operation control and equipment occupation small space effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

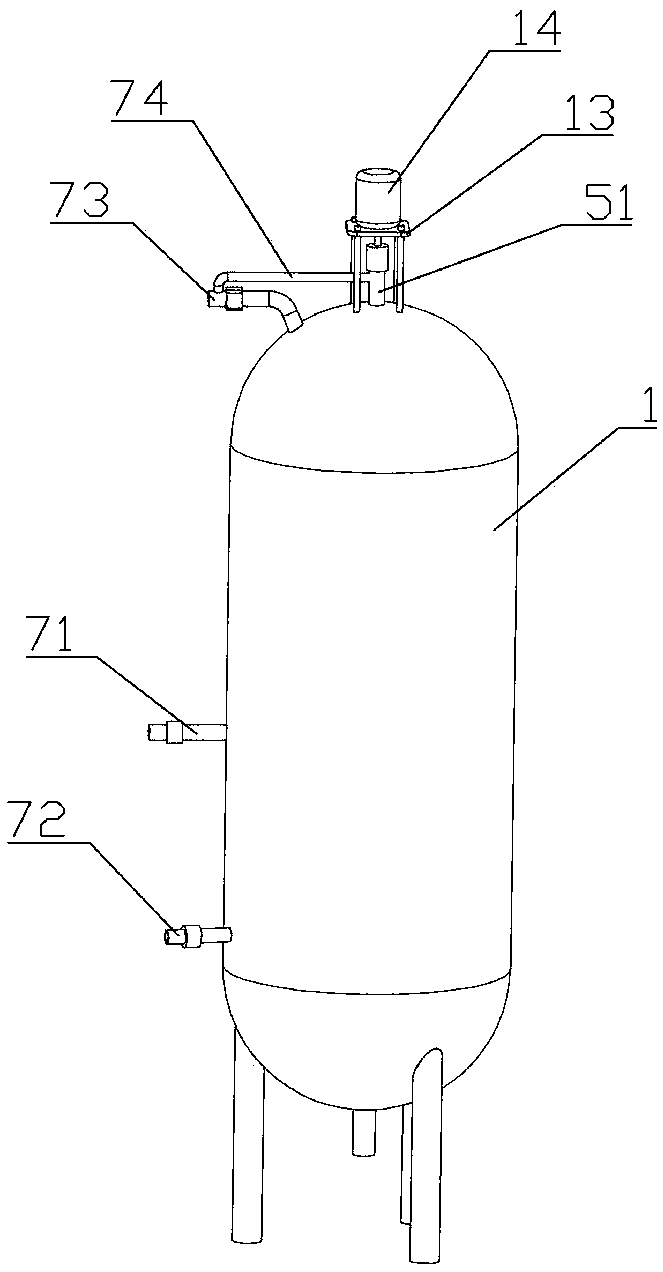

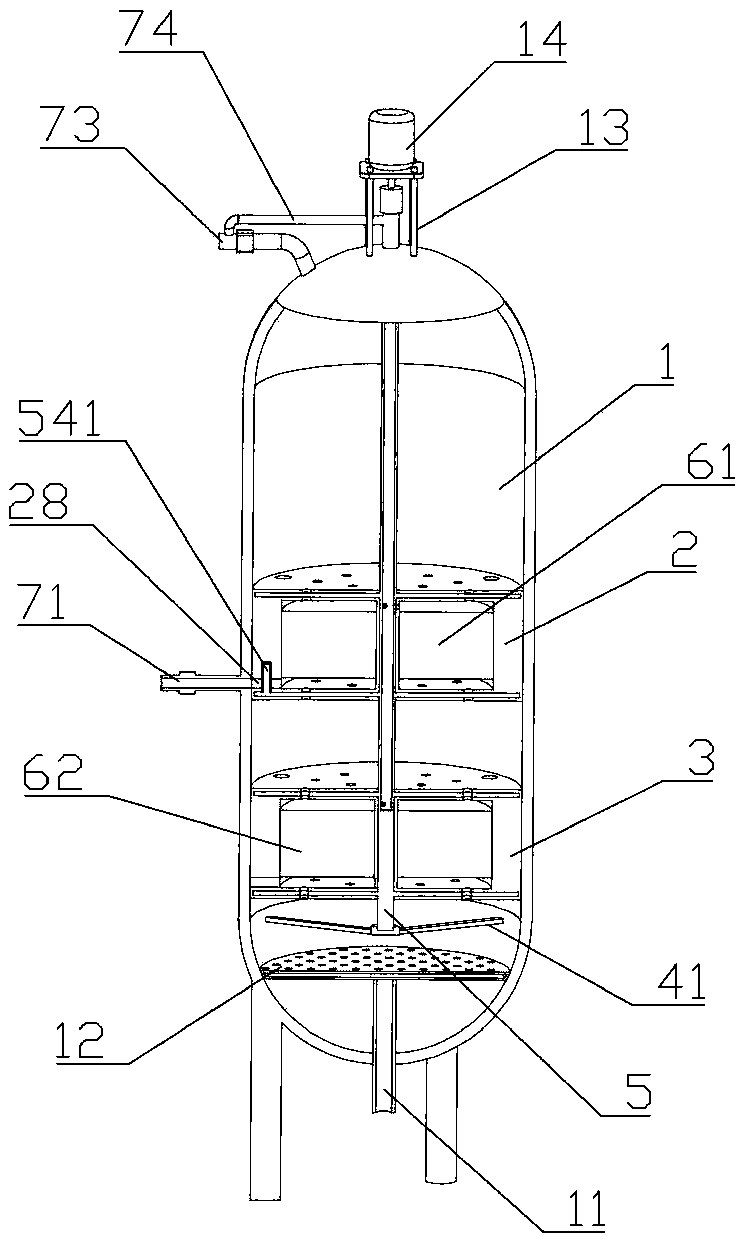

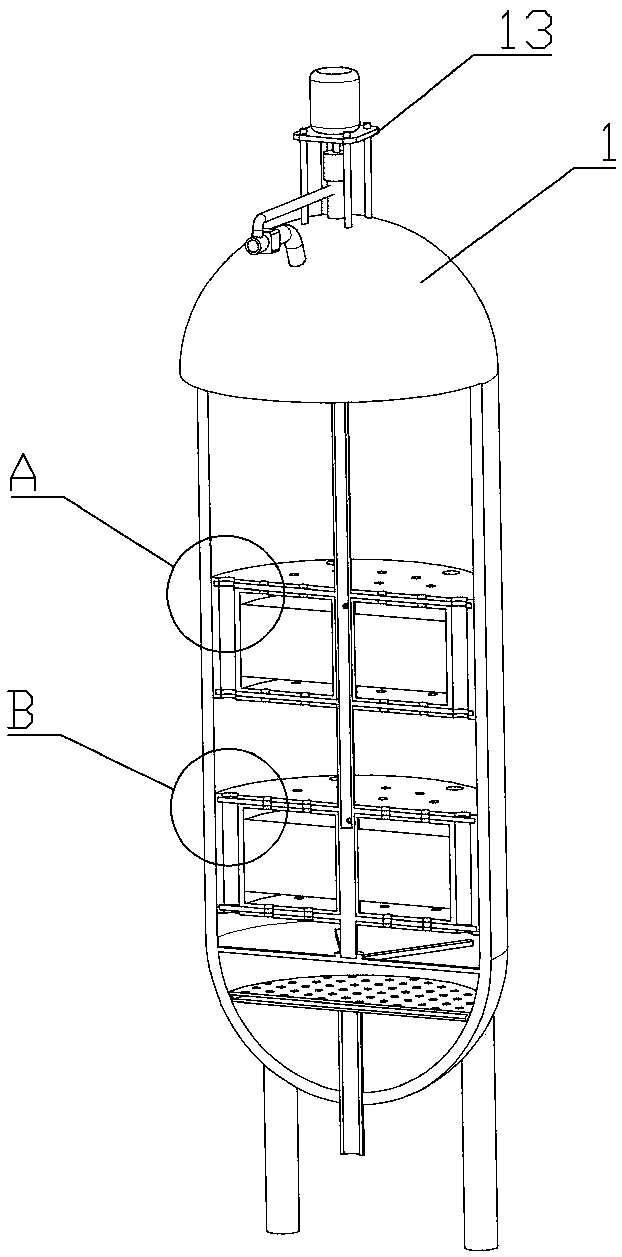

[0027] like Figure 1-7 As shown, a circulating oxygen production equipment, connected air compressor, filter, degreaser, dryer, molecular sieve adsorption tower, membrane separator and oxygen storage tank, filter connected to degreaser, degreaser connected to compression The machine and the compressor are connected to the drier, the drier is connected to the molecular sieve adsorption tower, the molecular sieve adsorption tower is connected to the membrane separator, and the membrane separator is connected to the oxygen storage tank. An exhaust pipe 73 is installed on the top, and a uniform flow plate 12 is installed in the tower body 1 and the lower end of the shaft core mounting frame 41, and the uniform flow plate 12 is connected to the intake pipe 11; the first molecular sieve filter 3 and the second molecular sieve filter 2 A sealing layer is installed between the tower body, and a guide frame 5 is installed in the tower body 1. The first molecular sieve filter 3 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com