A preparation method of anti-oxidation high-density polyethylene resin special for cosmetic bottles

A high-density polyethylene and anti-oxidation technology, which is applied in the field of polyethylene preparation, can solve the problems of inability to achieve long-term anti-oxidation and aging resistance, poor processability of plastic melts, and influence on the safety of cosmetics, so as to improve the shear rate. Sensitivity, good processability, high strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

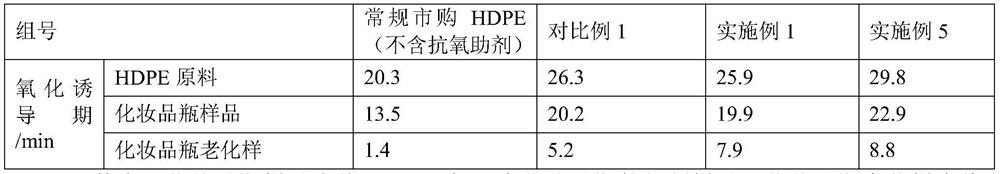

Examples

preparation example Construction

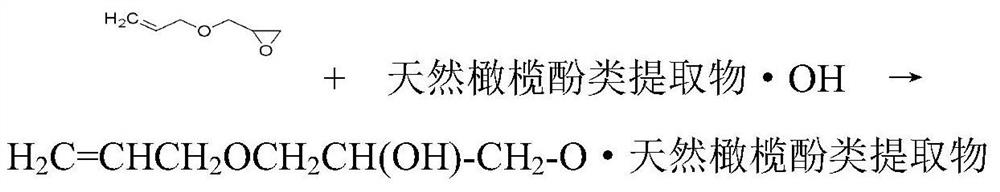

[0037]Preparation of modified natural olive phenolic extract:

[0038]The natural olive phenolic extract and the ring-opening catalyst (resin loaded with tin chloride) are added to the ethanol aqueous solution with a concentration of 60-80wt%, wherein the concentration of the modified natural olive phenolic extract in the ethanol aqueous solution is 5-15wt%, the mass of the ring-opening catalyst is 1-3% of the modified natural olive phenolic extract.

[0039] Under agitation, the temperature is raised to 75-85°C, and allyl glycidyl ether is continuously added dropwise. The reaction is stirred and the reaction temperature is maintained at 60-65°C. After the reaction is completed, the temperature is reduced to room temperature, the ring-opening catalyst is recovered, and then reduced Rotary evaporation is concentrated to remove the ethanol aqueous solution and allyl glycidyl ether, and finally the modified natural olive phenol extract is obtained after vacuum drying.

[0040]The preparation o...

Embodiment 1

[0046]raw material:

[0047]The purity of ethylene gas is ≥99%, the CO content is less than 43.0mg / kg, CO2The content is less than 44.0mg / kg.

[0048]The purity of 1-butene gas is ≥97%, the water content is less than 425mg / kg, and the total sulfur content is less than 410mg / kg.

[0049]The purity of hydrogen ≥95%, the CO content is less than 45.0mg / kg, CO2The content is ≤10.0mg / kg.

[0050]Preparation of modified natural olive phenolic extract:

[0051]The natural olive phenolic extract and the ring-opening catalyst (resin loaded with tin chloride) are added to the ethanol aqueous solution with a concentration of 70wt%, wherein the concentration of the modified natural olive phenolic extract in the ethanol aqueous solution is 10t% The mass of the ring-opening catalyst is 2% of the modified natural olive phenolic extract.

[0052]Under stirring conditions, the temperature was raised to 80°C, and allyl glycidyl ether was continuously added dropwise. The reaction was stirred and the reaction temperature...

Embodiment 2

[0059]raw material:

[0060]The purity of ethylene gas is ≥99%, the CO content is less than 43.0mg / kg, CO2The content is less than 44.0mg / kg.

[0061]The purity of 1-butene gas is ≥97%, the water content is less than 425mg / kg, and the total sulfur content is less than 410mg / kg.

[0062]The purity of hydrogen ≥95%, the CO content is less than 45.0mg / kg, CO2The content is ≤10.0mg / kg.

[0063]Preparation of modified natural olive phenolic extract:

[0064]The natural olive phenolic extract and the ring-opening catalyst (resin loaded with tin chloride) are added to the ethanol aqueous solution with a concentration of 65% by weight, wherein the concentration of the modified natural olive phenolic extract in the ethanol aqueous solution is 8% by weight The mass of the ring-opening catalyst is 1.5% of the modified natural olive phenolic extract.

[0065]Under stirring conditions, the temperature was raised to 82°C, and allyl glycidyl ether was continuously added dropwise. The reaction was stirred and the re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap