Isothermic shift process matched with pulverized coal gasification

An isothermal transformation and pulverized coal technology, which is applied in the field of temperature transformation, can solve the problems of increasing operating costs, inability to solve steam pressure, frequent replacement, etc., and achieves the reduction of equipment and pipeline investment, which is conducive to stable operation and reduces equipment investment. Effect

Active Publication Date: 2018-12-21

SINOPEC NINGBO ENG +2

View PDF8 Cites 7 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] In the isothermal shift, the fluctuation of the reaction temperature at the beginning and end of the CO shift will be transmitted to the heat transfer tubes used for heat transfer in the reaction bed, which will cause fluctuations in the temperature and pressure of the steam produced in the heat transfer tubes, especially with the increase in the size of the CO shift device And multi-serialization, the amount of rich steam is increasing, but the isothermal shift reactor has not been able to solve the fluctuation of steam pressure and the increase of investment in related equipment and pipeline engineering

In the isothermal shift process developed in recent years, the pressure of the medium-pressure steam produced by the isothermal shift furnace is unstable. Especially in the final stage of the reaction, as the catalyst activity decreases, the isothermal shift reaction temperature needs to be increased to maintain the shift reaction conversion. If the rate is high, the pressure of the medium-pressure steam produced by the isothermal shift furnace will fluctuate violently, which will seriously affect the stable operation of the device and even the steam pipe network of the whole plant.

[

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

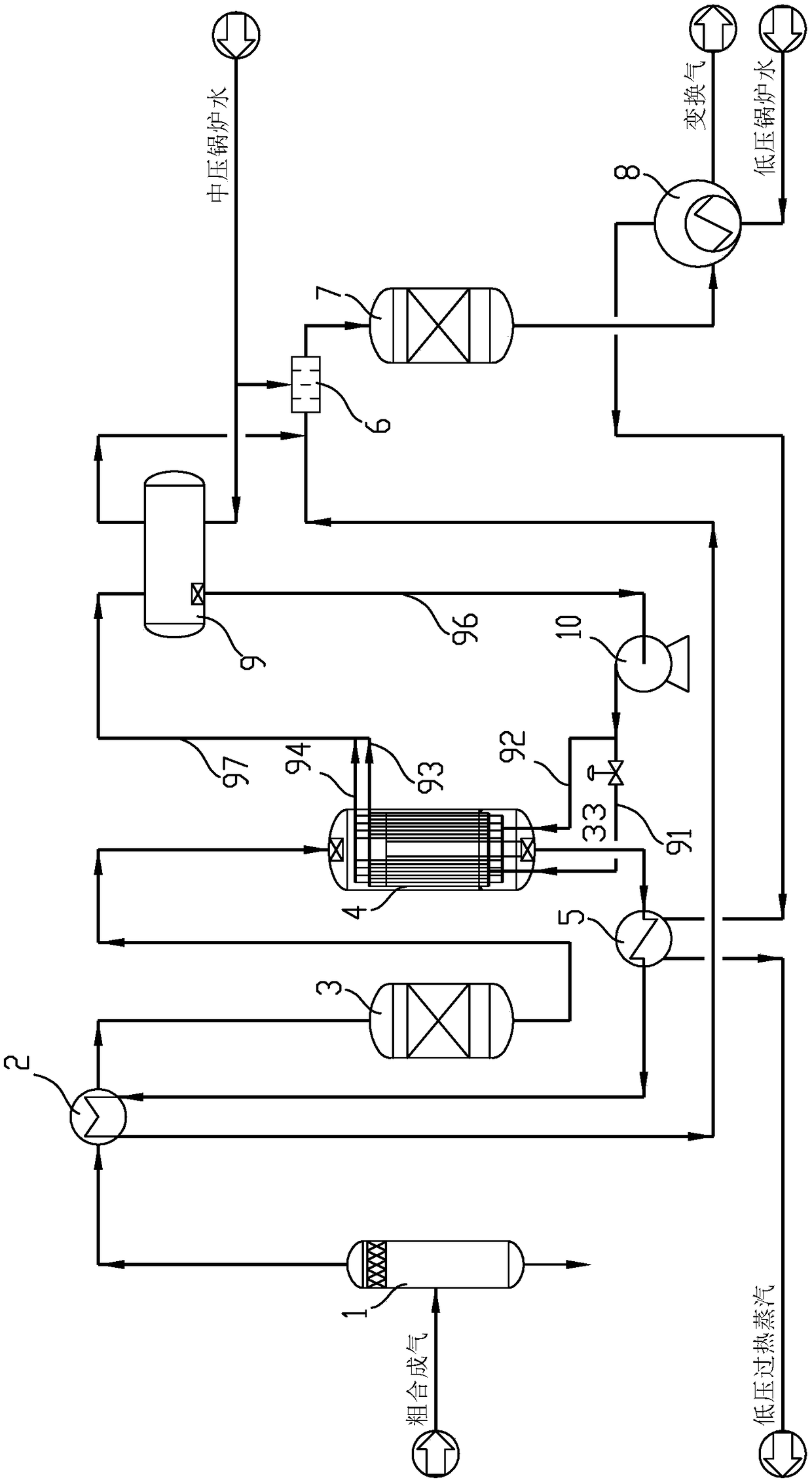

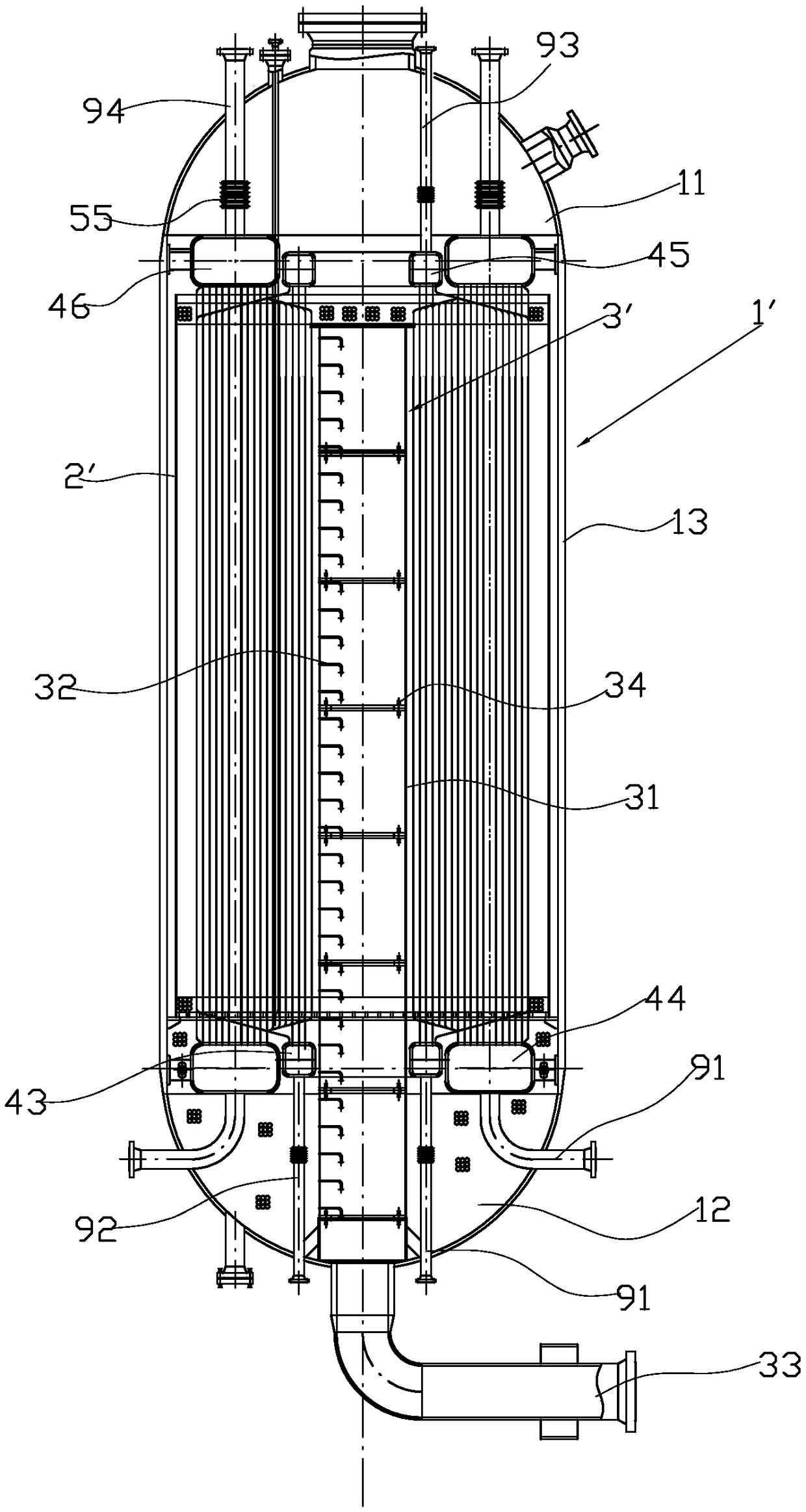

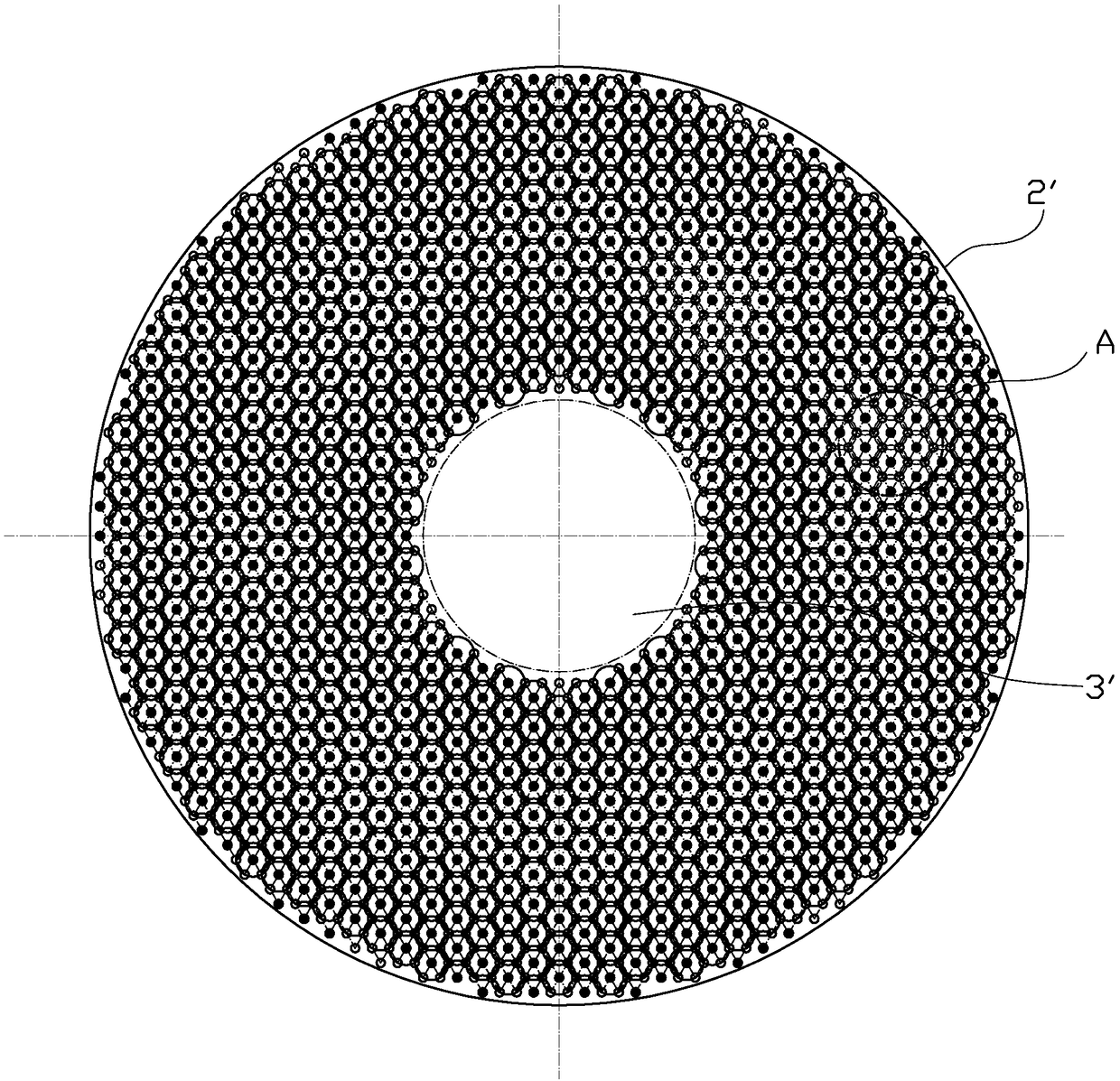

The invention relates to an isothermic shift process matched with pulverized coal gasification. An isothermic shift converter is included in the process; the process is characterized in that two groups of heat exchange pipes are arranged in the isothermic shift converter; after a liquid phase is separated from crude synthetic gas, the crude synthetic gas is subjected to heat exchange and impurityremoval and then sent into the isothermic shift converter for a primary shift reaction; medium-pressure boiler water in a steam drum enters the two groups of heat exchange pipes for heat exchange witha catalyst bed layer in the isothermic shift converter to generate steam, primary shift gas coming from the isothermic shift converter is sent into a thermal insulation shift converter for a secondary shift reaction, and secondary shift gas is obtained; the dry basis content of CO in the secondary shift gas in the thermal insulation shift converter is monitored, when the dry basis content of CO in the secondary shift gas is larger than 1.2v%, one group of heat exchange pipes are closed, the other group of heat exchange pipes work, and the activity requirement of a catalyst and the constant yield are guaranteed under the condition that a steam pipe network is not changed.

Description

technical field [0001] The invention relates to the technical field of carbon monoxide conversion, and specifically refers to an isothermal conversion process for supporting pulverized coal gasification. Background technique [0002] Based on the current situation of my country's resources with more coal, less oil and less gas, the chemical industry using coal as raw material has developed rapidly in recent years, and pulverized coal gasification has been widely used due to its characteristics of wide adaptability to coal types, high energy utilization rate and high gas production capacity per unit of equipment. application. Coal is gasified at high temperature to produce H 2 The crude synthesis gas with CO as the main component is a suitable raw material for the production of C1 chemical industry and its derivatives. The crude synthesis gas produced by pulverized coal gasification process is mainly composed of CO, CO2 and H 2 , and its follow-up is equipped with a CO conv...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C10J3/82C10J3/46

CPCC10J3/46C10J3/82C10J2300/093C10J2300/1603Y02P20/10

Inventor 许仁春唐永超亢万忠涂林李怀双陈冬景程世权周金路刘宏先

Owner SINOPEC NINGBO ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com