Production, extraction and purification technology of DHA-enriched algae oil

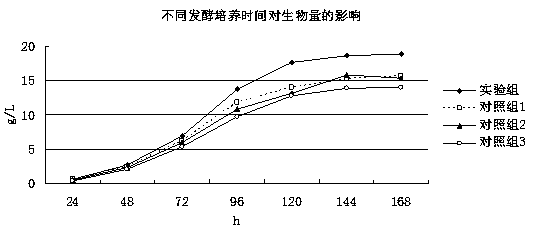

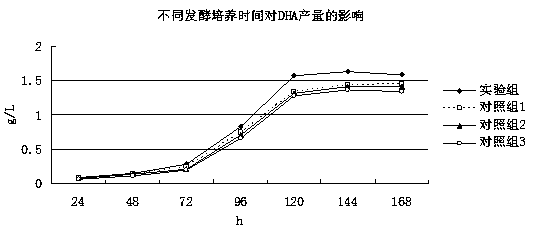

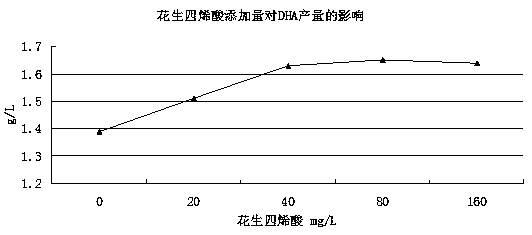

A technology and technology of algae oil, which is applied in the field of production, extraction and purification of DHA-rich algae oil, can solve the problems of unsatisfactory biomass and DHA production, meet the needs of algae growth and product accumulation, and reduce the production of DHA Cost, the effect of increasing DHA production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The production, extraction and purification process rich in DHA algae oil, it comprises the following steps:

[0041] Activate the Cryptidinium ATCC30772 preserved on the slant, and then insert it into a 2L culture flask filled with 500mL shake flask seed medium for shake flask seed culture. Cultivate at 120rpm at 25°C for 48h, and then inoculate according to the inoculum size of 5%. Cultivate in a seed tank equipped with 50L seed tank culture medium, the culture conditions are: 180rpm, 25°C, ventilation rate 0.8vvm, cultivate for 48h, and obtain Cryptidinosa seed liquid, the biomass of which is 3.2g / L after detection;

[0042] The components of the shake flask seed culture medium and the seed tank culture medium are: glucose 10g / L, sodium chloride 5g / L, ammonium sulfate 2g / L, magnesium chloride 0.1g / L, potassium dihydrogen phosphate 0.1g / L ;

[0043] Inoculate the seed solution of Cryptodinium algae into the reaction tank containing the fermentation medium according t...

Embodiment 2

[0049] The production, extraction and purification process rich in DHA algae oil, it comprises the following steps:

[0050] Activate the Cryptidinium preserved on the slant, and then insert it into a 2L culture flask containing 500mL shake flask seed medium for shake flask seed culture, cultivate it at 120rpm at 25°C for 48h, and then inoculate it with an inoculum of 3%. Cultivation was carried out in the medium of the seed tank, the cultivation conditions were: 180rpm, 25°C, ventilation rate 0.5vvm, and cultivation for 72h to obtain the seed liquid of Cryptidoflagellate, with a biomass of 4.5g / L;

[0051] The components of the shake flask seed culture medium and the seed tank culture medium are: glucose 10g / L, sodium chloride 5g / L, ammonium sulfate 2g / L, magnesium chloride 0.1g / L, potassium dihydrogen phosphate 0.1g / L ;

[0052] Inoculate the seed solution of Cryptodinium algae into the reaction tank containing the fermentation medium according to the inoculum amount of 5%,...

Embodiment 3

[0058] The production, extraction and purification process rich in DHA algae oil, it comprises the following steps:

[0059] Activate the Cryptidium preserved on the slant, and then insert it into a 2L culture flask containing 500mL shake flask seed medium for shake flask seed culture, cultivate it at 120rpm at 25°C for 48h, and then inoculate it into the Cultivation was carried out in the seed tank culture medium, the cultivation conditions were: 180rpm, 25°C, ventilation rate 0.6vvm, and cultivation for 60h to obtain Cryptidinosa seed liquid with a biomass of 4.1g / L;

[0060] The components of the shake flask seed culture medium and the seed tank culture medium are: glucose 10g / L, sodium chloride 5g / L, ammonium sulfate 2g / L, magnesium chloride 0.1g / L, potassium dihydrogen phosphate 0.1g / L ;

[0061] Inoculate the seed liquid of Cryptodinium algae into the reaction tank containing the fermentation medium according to the inoculum amount of 4%, cultivate at 25°C, and the aera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com