Assembled steel pipe concrete laminated column-beam structure system with multiple built-in steel pipes

A technology of concrete filled steel tube and inner steel tube, which is applied in the direction of building structure and construction, can solve problems such as lack of new forms, and achieve the effects of avoiding construction complexity, increasing assembly efficiency, and improving seismic energy dissipation performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The specific embodiments of the present invention will be described in detail below with reference to the drawings.

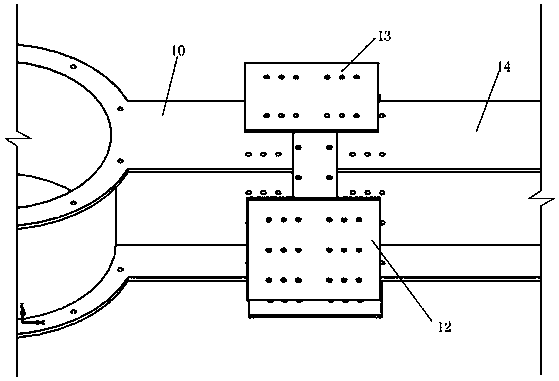

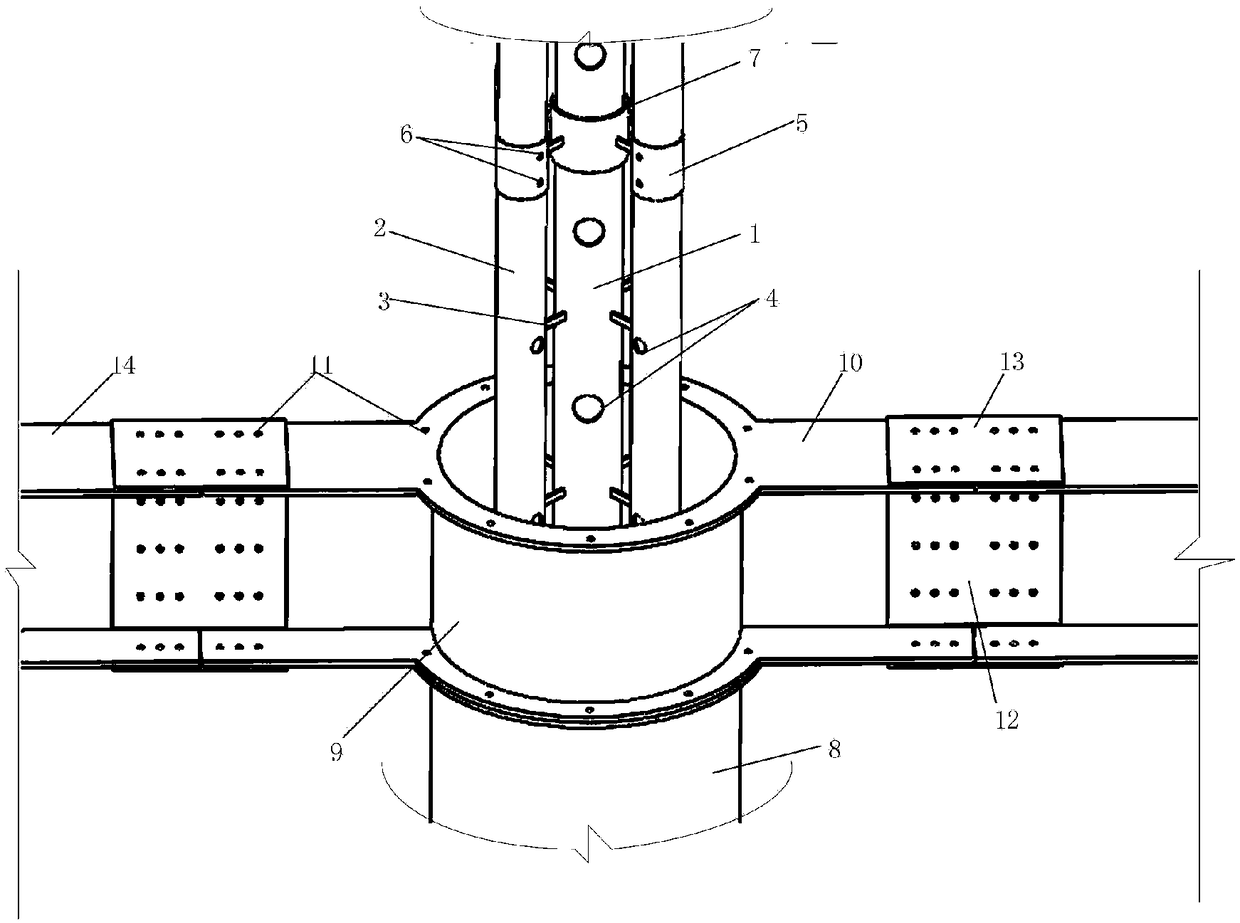

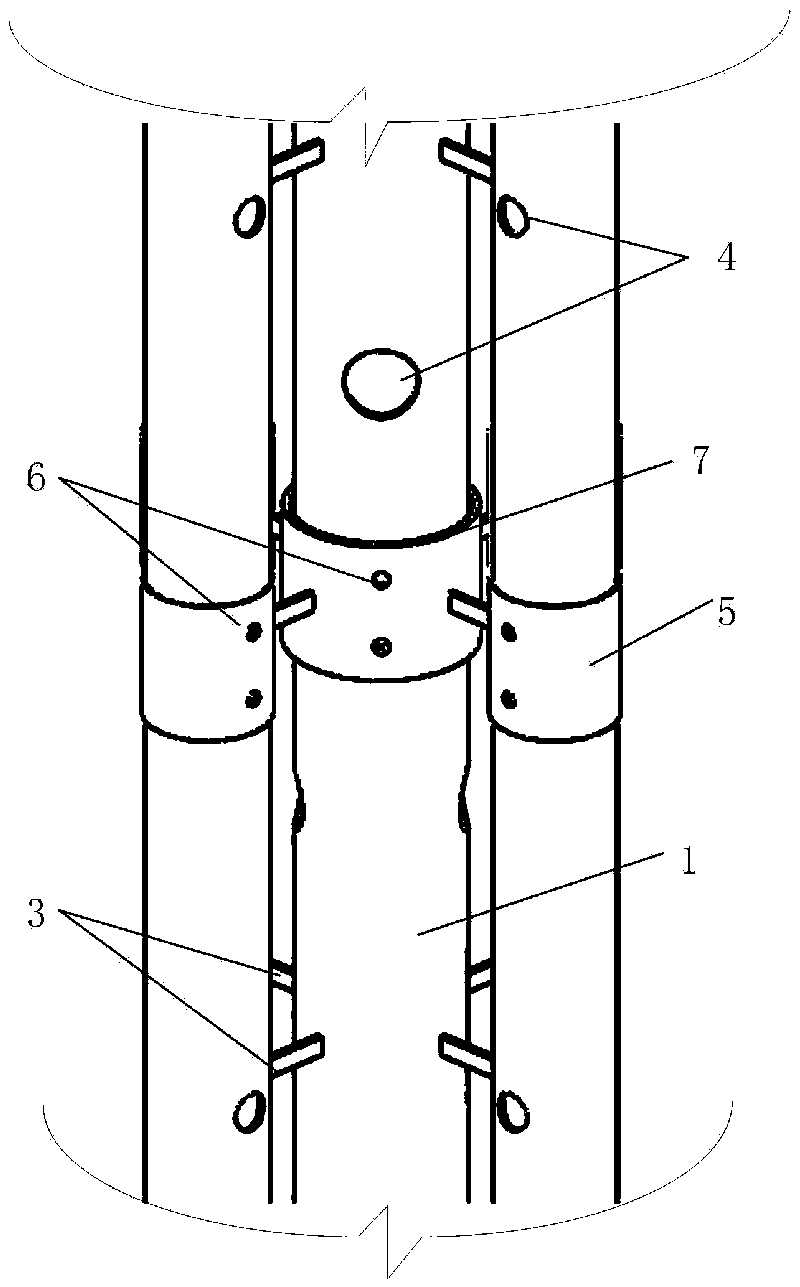

[0031] Such as figure 1 with Image 6 As shown, the prefabricated concrete-filled steel tube composite column-beam structure system with built-in multiple steel pipes mainly includes large-diameter inner steel pipes in the center, small-diameter inner steel pipes in the periphery, mild steel connectors, flow holes, inner pipe casings, and single-sided bolts. , Rubber gaskets, outer steel pipes, outer pipe connecting pipes, extension beam ends, high-strength bolts, beam web connecting plates, beam flange connecting plates and beams. The central large-diameter inner steel pipe is connected to the surrounding small-diameter inner steel pipe through a low yield point steel connector to form a prefabricated built-in multi-steel pipe. The prefabricated built-in multi-steel pipe is provided with flow holes, and the prefabricated built-in multi-steel pipe is 1 / 2 to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com