Steel structure of prestressed high-strength concrete pipe pile body

A high-strength concrete, prestressed technology, applied in the direction of foundation structure engineering, sheet pile wall, construction, etc., can solve the problems to be improved, limit the popularization and application of PHC piles, etc., to improve the integrity, enhance the flexural performance, increase the shear resistance The effect of carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

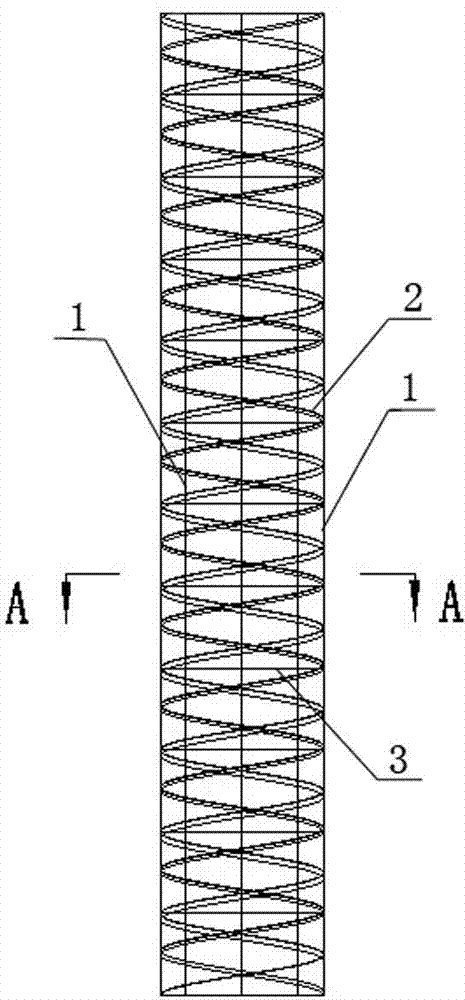

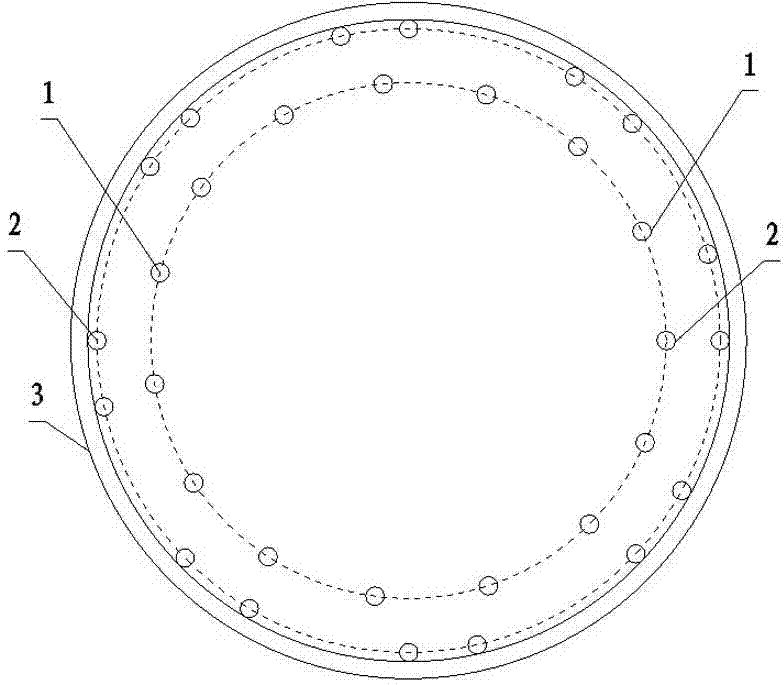

[0011] The steel structure of the prestressed high-strength concrete pipe pile body includes a number of prestressed longitudinal reinforcements 1, a spiral mesh cylinder 2 and a number of annular stirrups 3, and the spiral mesh cylinder 2 is made of a plurality of steel wires that are rotated at a certain pitch at a helix angle. It is formed by crossing and binding together in opposite directions. The plurality of prestressed longitudinal ribs 1 are evenly arranged in the circle formed by the spiral mesh cylinder 2 along the circumferential direction. The formed circles are concentric, and the several annular stirrups 3 are evenly bound on the outside of the spiral mesh cylinder 2 from top to bottom.

[0012] Further, the number of steel wires in the spiral mesh cylinder 2 is equal to the number of prestressed longitudinal bars 1 . It can ensure the synchronous improvement of the flexural bearing capacity and the shear bearing capacity of the pile body along the hoop dire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com