Railway access door management system and railway access door system

A management system and access door technology, which is applied in the field of railway access door management system and railway access door system, can solve the problems of chaotic management of access doors along the railway line and large safety hazards, so as to reduce the pressure of personnel access management and reduce safety hazards , to ensure the effect of safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

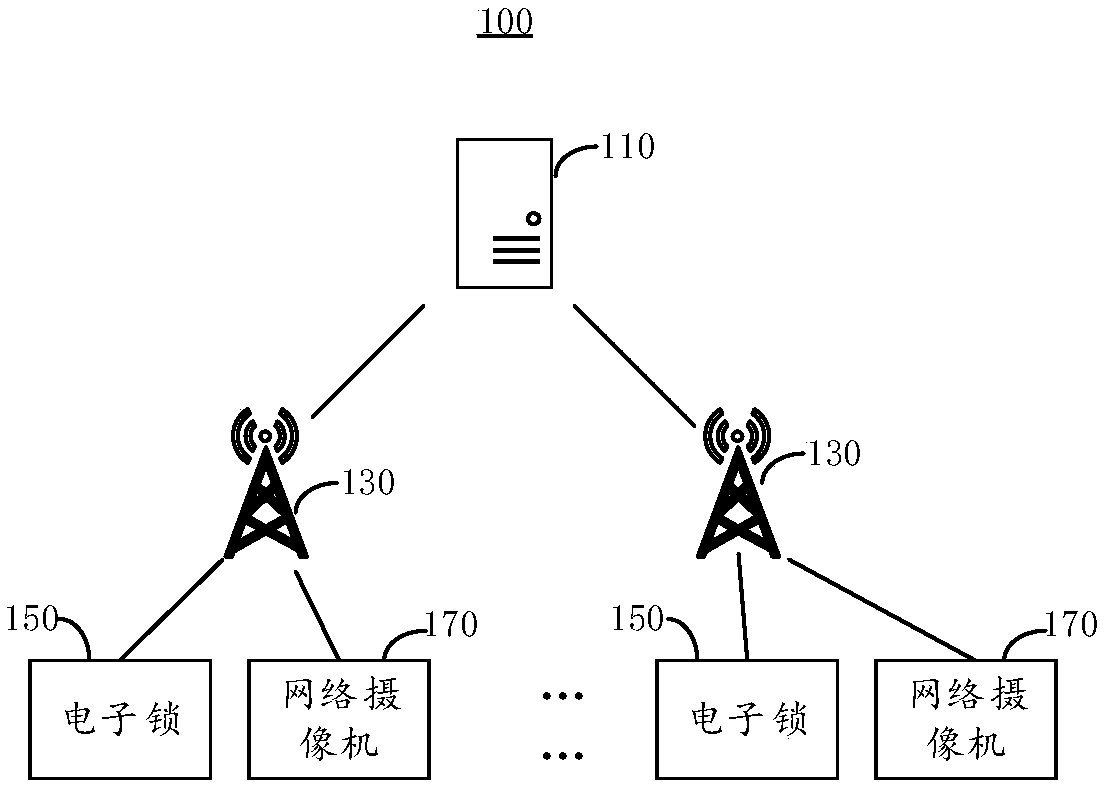

[0032] This embodiment provides a railway access door management system 100 to improve the existing problems of difficult management of railway access doors and a large number of potential safety hazards. see figure 1 , figure 1 A schematic diagram of the railway access door management system 100 provided in this embodiment is shown.

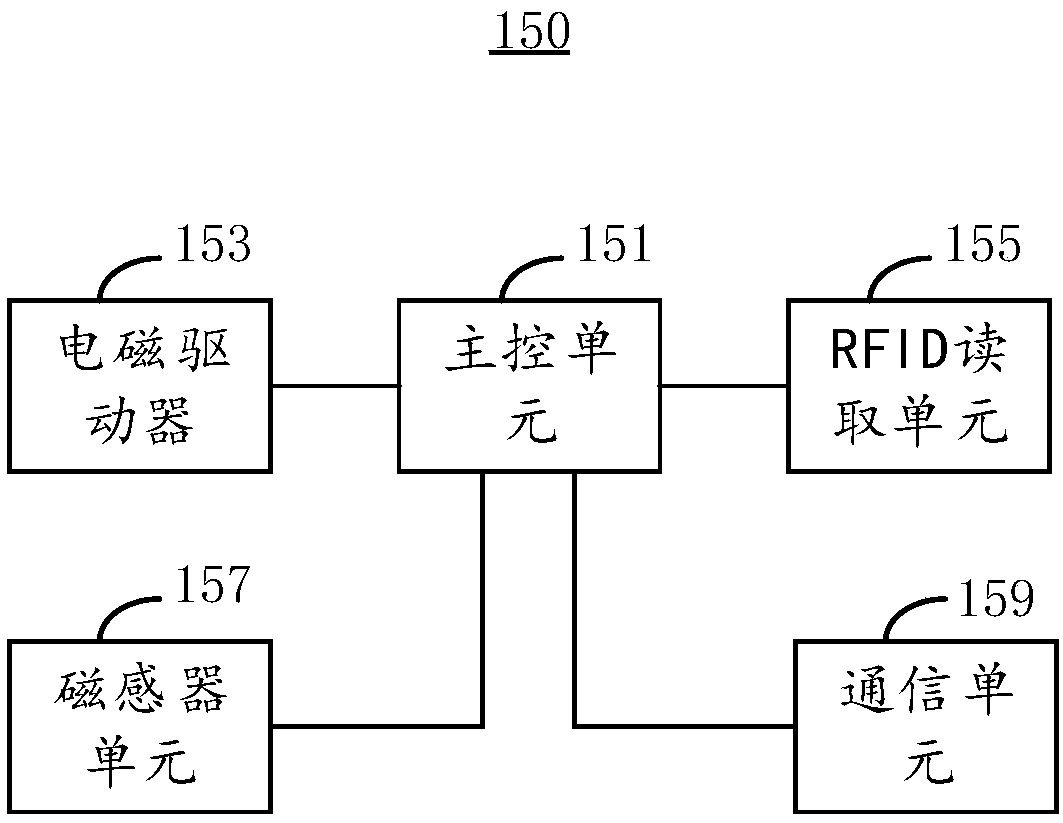

[0033] The railway access door management system 100 includes a monitoring platform 110 , a plurality of base stations 130 , a plurality of electronic locks 150 and a plurality of network cameras 170 . Wherein, each railway access door is provided with an electronic lock 150 and a network camera 170, and a plurality of base stations 130 are connected to the monitoring platform 110 in communication, and each base station 130 is correspondingly connected to a plurality of electronic locks 150 and network cameras 170 in communication. The base station 130 is used to establish communication between the electronic lock 150 , the network camera 170 ...

no. 2 example

[0057] This embodiment provides a railway access door system. The railway access door system includes a plurality of access doors and a railway access door management system 100. The railway access door management system 100 includes a plurality of electronic locks 150, and each railway access door is equipped with an electronic lock. A lock 150, the electronic lock 150 is used to control the opening or closing state of the access door.

[0058] It should be noted that the structure and basic principles of the railway access door management system 100 provided in this embodiment are roughly the same as those of the railway access door management system 100 provided in the first embodiment, and will not be repeated for a brief description of this embodiment. For details, please refer to the relevant content in the first embodiment for details that are not introduced in this embodiment.

[0059] In summary, the present invention provides a railway passage door management system ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com