Pressure switch suitable for pump

A technology of pressure switch and switch seat, which is applied to components, pumps, and pump control of elastic fluid pumping devices. It can solve the problems of water pump control failure, pressure switch start-up damage, and the switch is easily blocked by impurities. The effect of improving the accuracy of the machining contact surface, improving the machining efficiency, and avoiding frequent movements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

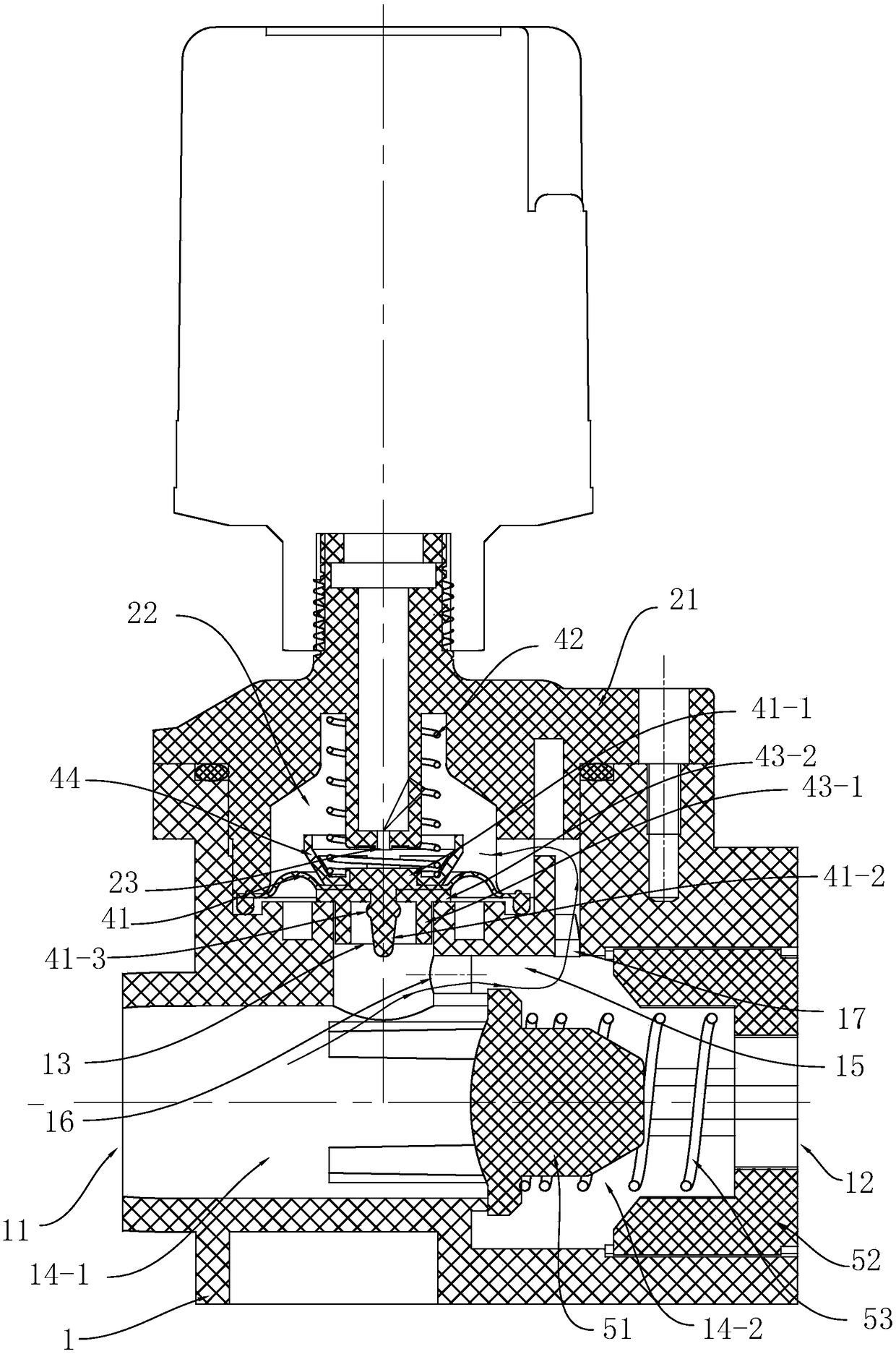

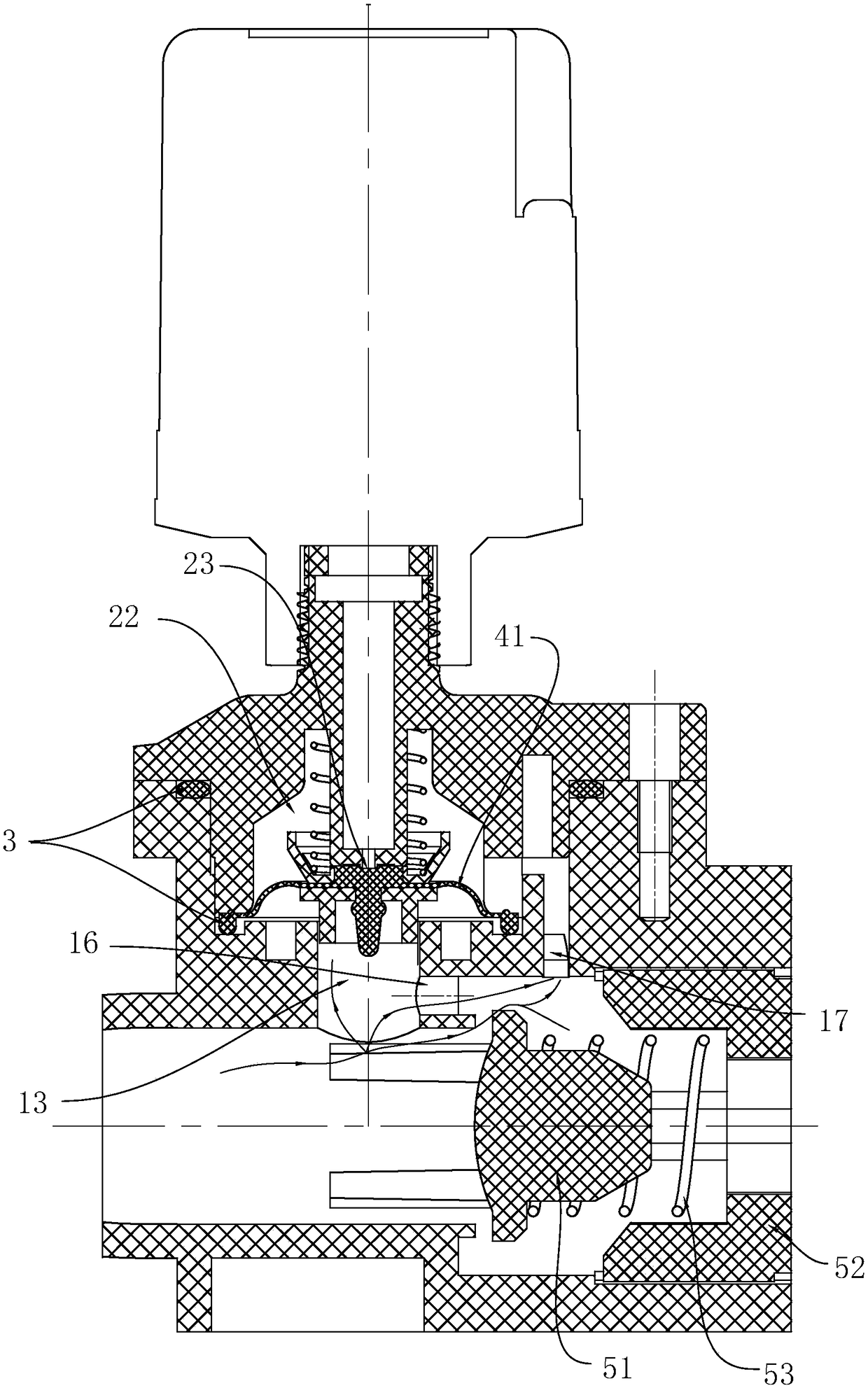

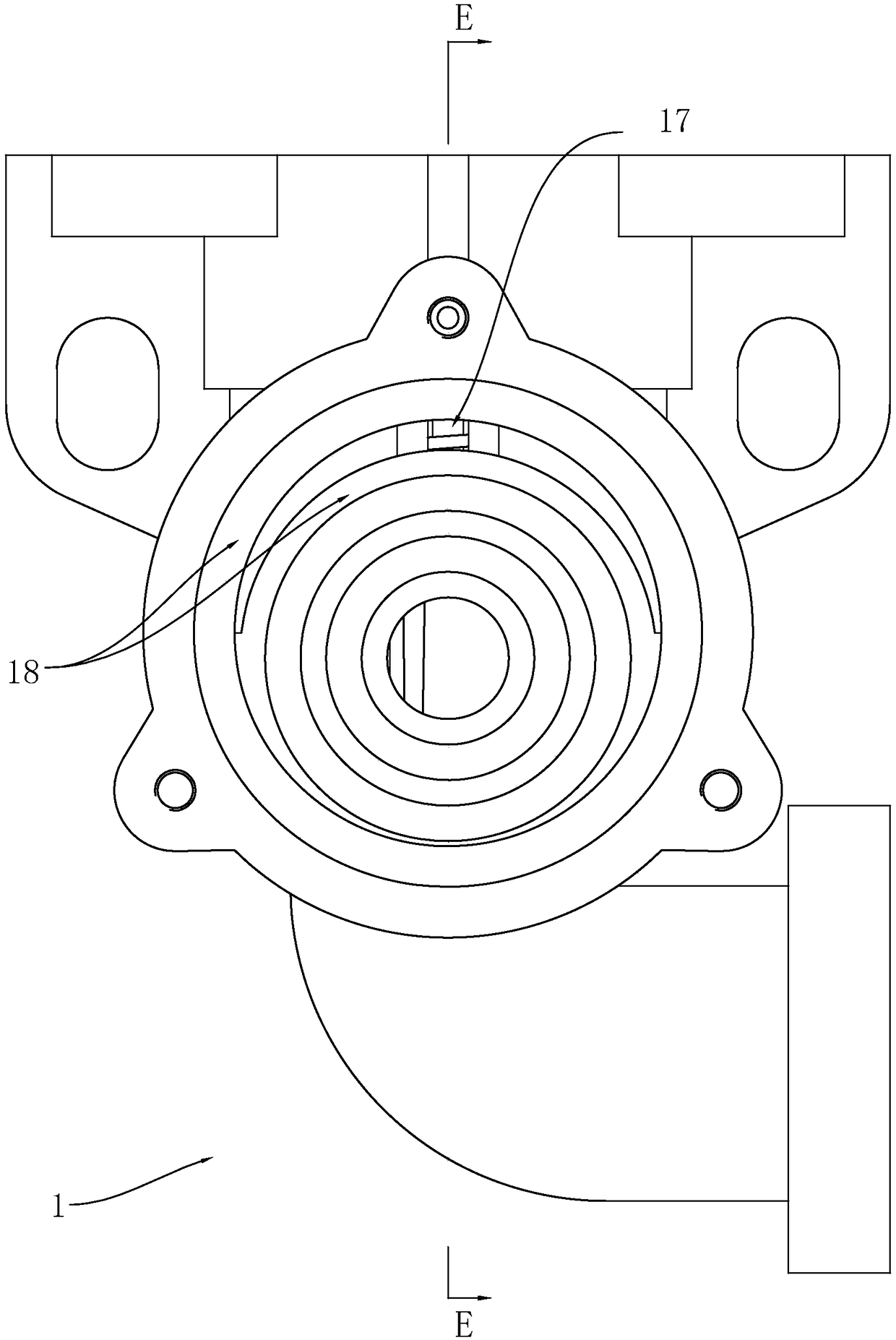

[0038] Example: such as Figure 1-7 shown, pressure switches suitable for pumps, including:

[0039] Check valve: including a valve seat 1 and a valve core, the valve seat is provided with a valve seat water inlet 11, a valve seat water outlet 12 and an external pressure taking port 13, and the valve seat is provided with a check channel and a discharge channel 15 , the valve seat water inlet 11 and the valve seat water outlet 12 are respectively located at both ends of the check channel, the valve core is arranged on the check channel 14, and the check channel includes a water inlet section 14- 1 and check section 14-2, the valve core body on the spool is located between the water inlet section and the check section, the water inlet end of the discharge channel is connected with the water inlet section, and the outer intake The pressure port is in communication with the water inlet section, and the water outlet end of the discharge channel 15 is in communication with the non...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com